A high-volume mould-maker for the French food processing industry says WorkNC, from Vero Software, is an “irreplaceable” asset to their production process. The software helped them to implement a completely automated workshop, freeing up time to take on new projects.

一家法国食品行业模具制造商说:Vero集团旗下的WorkNC软件在他们产品加工中占有不可以替代的地位。WorkNC帮助他们实现自动化加工、提高加工效率、承接更多订单。

Société Nouvelle Caulonque, based at Soustons, manufactures multiple cavity thin-walled moulds for thermoplastic injection and thermoforming.

Société Nouvelle Caulonque坐落在法国 Soustons, 是一家制造多种类型的注塑模具和热成型的腔体薄壁模具供应商。

“Everythingis manufactured with WorkNC, which has allowed us to considerably reduce machining times,” says Production Manager Stéphane Rousseau. “We can produceparts much quicker, enabling us to accept new projects.”

“用WorkNC加工,使我们全面提高了加工效率”生产经理Stéphane Rousseau说。“WorkNC使我们零部件加工效率更高、能够承接更多新订单”

Once a job enters the programming phase it’s distributed amongst four full-time programmers, and each design is tailored to theirclients’individual needs. “We never re-use an existing mould process– we recreate them each time to make improvements, ensuring our clients benefit from new technologies and manufacturing methods.”

他们会把编程工作分配给四个全职编程人员,为满足客户需要量身定制。“我们从来不会重复使用现有的模具加工程序,我们每一次都重新创建新的且更先进的程序,保证我们的客户能够从新技术和加工方法中获益”。

WorkNC allows them to be highly responsive and flexible,reducing programming time from two weeks to less than half a day. “Sometimes, we’ve even been threeweeks ahead of schedule on ten different jobs.”

WorkNC使得他们的工作效率更高、更加灵活,将编程时间从两个星期缩短到半天。“有时候,在同时处理10项不同工作的时候,利用WorkNC,我们能比预定计划提前3周完成。”

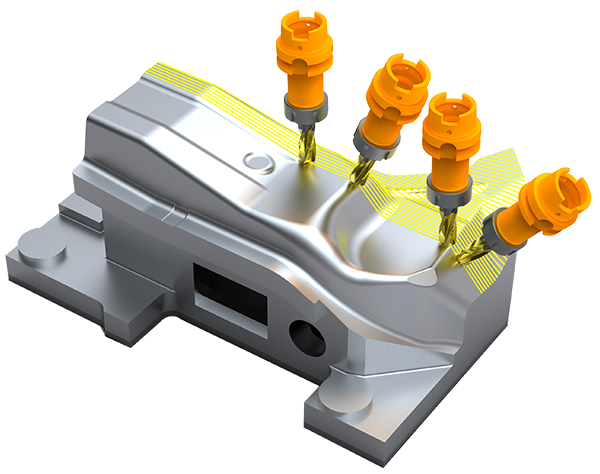

Société Nouvelle Caulonque has invested in eight CNC machine tools which are programmed withWorkNC – one5-axis Mazak, three 3-axis Mazak roughing machines, one 3-axis OKK, two 5-axis OKK and one 5-axis GF MIKRON. The workshop functions 24/7.

Société Nouvelle Caulonque厂房面积1750平方米,42名员工,8台CNC加工中心都配置了WorkNC:一台五轴Mazak 、3台三轴Mazak 、一台三轴OKK、两台5轴OKK、一台五轴GF MIKRON,24小时开机。

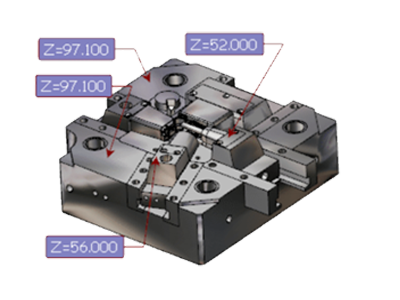

“WorkNC enables us to manufacture large quantities of thin-wall moulds for producing plastic containers for the agri-food industry. Our clients are very demanding in terms of quality. With this type of packaging at such a high density, anexcess thickness of just 0.01mm can lead to a weight variation of more than 0.2g per unit, which is unacceptable for our customers. They need a maximum variation of 0.1g.”

“WorkNC能够使我们大批量制造模具,我们生产的是包装鲜活农产品的塑料集装箱薄壁模具,所以用户对质量要求特别高,要求包装承重能力好、要轻薄,而仅仅0.01mm的薄度就会使得每个塑料集装箱的重量变化幅度大于0.2千克,这对于我们用户是无法接受的。他们能够接受的包装重量最大变化是0.1千克。”

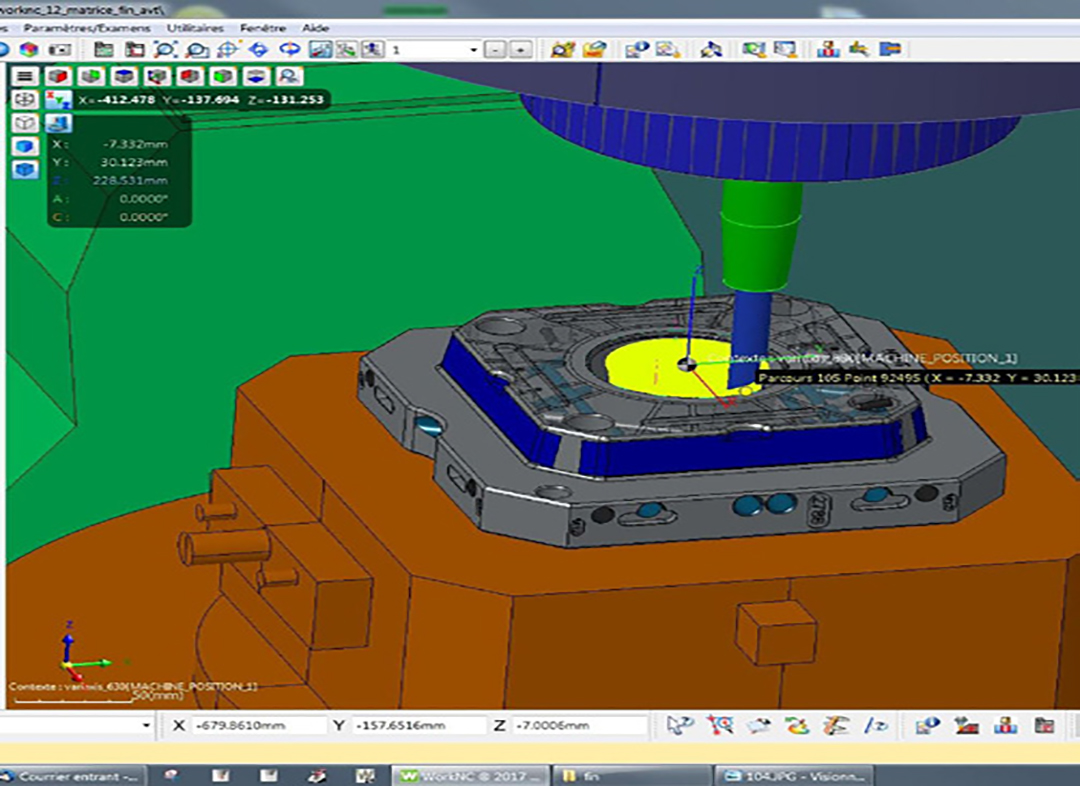

Thanks to WorkNC he says they have significantly raisedquality levels in terms of precision. The manufacturing process for all Société Nouvelle Caulonque’sproducts is now fully controlled using a combination of WorkNC CAD and WorkNC2017 R1. The native CAD files, designed with Solid Edge, are easily opened thanks to the WorkNC’s direct translators which have been continuously developed to provide an optimum level of performance and reliability when opening native CAD files.

他说:幸亏有WorkNC,他们才能够显著提高加工精度。如今,所有Société Nouvelle Caulonque 产品加工都用WorkNC CAD功能和WorkNC 2017 R1 。WorkNC可以直接导入并轻松打开Solid Edge做的原始设计文件,这个功能还在持续更新、优化中,同时使打开原始文件时更加可靠。

Eachmould to be produced is analysed in the CAM functionality to ensure 100 percent programmed production. When a project is launched in the engineering office we create a layer management system consisting of files containing different protected areas, which allows us to reduce machining times. We’re able to design the moulds in such a way that we can obtain repeatable strategies,programming jobs much more rapidly.

“WorkNC CAM 可以分析每一个将被生产的模具,确保他们都是100%标准化生产。当我们工程部门启动一个项目时,我们会创建编程模板系统,不同的部位应用不同的加工方法,这使我们能够缩短时间。用这种方式获得可重复利用的策略,提高编程效率。”

“We have standardised methods between the engineering office and workshop, so that tool libraries created in WorkNC are now physically available at the NC machinetool. We also use WorkNC CAD to produce our electrodes.”

“我们在工程办公室和工厂之间建立了标准化加工方式,WorkNC建立的刀具库可以直接应用于NC加工中心。我们也会利用WorkNC的CAD功能生产电极。”

Sociéphane Rousseau finds undercut machining to be highly beneficial for their manufacturing process, along with feature recognition, die flats roughing/finishing and flatsurface finishing toolpaths.

Stéphane Rousseau发现利用WorkNC底刃加工可以有效提高加工效率。WorkNC能够特征化识别加工区域,强大的开粗和精加工功能,以及安全稳定的平面精加工路径。

And the company specifically requested one particularitem of functionality – 3D tool compensation. “Before this wasincluded in the software we had to program toolpaths with different positiveand negative stock allowances, because it was impossible to obtain dimensional data results prior to machining. A mould was programmed three or four times to anticipate these differences – programming a mould represents around 80 different toolpaths – so it was long and tedious. But the WorkNC R & D team worked closely with us to develop the 3D tool compensation.

“Thismeans we can re-run toolpaths with the correct allowance on NC machines which aren’tequipped with their own 3D tool compensation feature.

公司还专门要求一个特别的功能-3D刀具补偿功能。在此之前,我们不得不将不同刀具的刀具路径程序编到软件里,一个模具需要被编程3-4次才能得到这些不同的结果,这是一个冗长又枯燥的过程。但是WorkNC研发部门与我们密切合作,给我们提供3D刀具补偿功能。

“这就意味我们能够重复使用刀具路径,安全应用于NC加工中心。”Stéphane Rousseau说。

He also developed functions allowing them to recoverand interpret measurements from a sensor fitted to the machine, and automatically feed the required adjustments to the WorkNC toolpaths, with the necessary toolpath offsets being taken into consideration by the 3D toolcompensation. The machine operates totally independently without any human intervention. “Withone single programming cycle we can finish the part whatever the measurement readings.”

他们还开发了这样的功能,能够读取传感器得到的测量结果,并通过WorkNC的三维刀具补偿来实现自动调整刀具的切削量,机床独立工作,无需人为干预。“无论测量结果显示是什么,只用一个指令就能完成”。

He says WorkNC’s great strengthis that its different functions ensure each phase of the manufacturing processit completely secure. “These include roughing strategies with dynamic tool and tool holder collision control, automatic stock model updating,machine simulation, along with 5-axis collision detection and machineout-of-limits management. No part has ever been scrapped since WorkNC was implemented.”

他说,WorkNC的最大优势就是能够确保每一个加工过程完全安全可靠。包括粗加工策略中的刀具、刀柄碰撞检查、机床模拟、5轴碰撞检测、机床极限管理。使用WorkNC之后从来没有出现过撞机。

The company has also invested in an OKK cell imported by Halbronn. The combined efforts of StéphaneRousseau to create the postprocessor along with the methodical work of the two operators - Fabrice Dulau and Tom Nelet - have led to the game-changing implementation of a fully automated process: an autonomous cell for producing high precision cavity moulds.

Société Nouvelle Caulonque已通过Halbronn采购了OKK 设备。通过Stéphane Rousseau和另外两位系统操作人员:Fabrice Dulau 和 Tom Nelet的共同努力建立的后处理,便于适用于各类机床,实现完全自动化加工:智能化生产高精度型腔模具。

In conclusion, Stéphane Rousseau says the software has become irreplaceable. “Since 2003programming with WorkNC has been the only manufacturing process in our 2D, 3Dand 5-axis strategies. It’s an integral element in our automated in-house manufacturing and control system for NC machines.

Stéphane Rousseau说:总之,对于他们公司而言,WorkNC是不可取代的。“从2003年开始,我们就一直用WorkNC 2D加工、3D 加工和WorkNC五轴加工。WorkNC帮助我们实现自动化生产、安全加工。”

“Thanks to WorkNC and our engineering department’s high level of expertise, Société Nouvelle Caulonque has never produced a dysfunctional mould.”

“感谢WorkNC 和我们专业的工程部门。正因为有他们,所以Société Nouvelle Caulonque从来没有生产过有瑕疵的模具。”

|

WorkNC

WorkNC