|

Vero Software GmbH has developed a new WorkNC high feed rate strategy together with the cutting specialists at Audi Toolmaking. Their achievement: Audi has reduced processing times in various pre-finishing pressing tools by up to 30 percent while tool service life has trippled at the same time.

Vero软件公司已经开发出一种新的WorkNC的高速进给策略并应用于奥迪制造。客户效果:奥迪已经在各种半精加工效率方面提高了30%,同时还延长了刀具使用寿命。

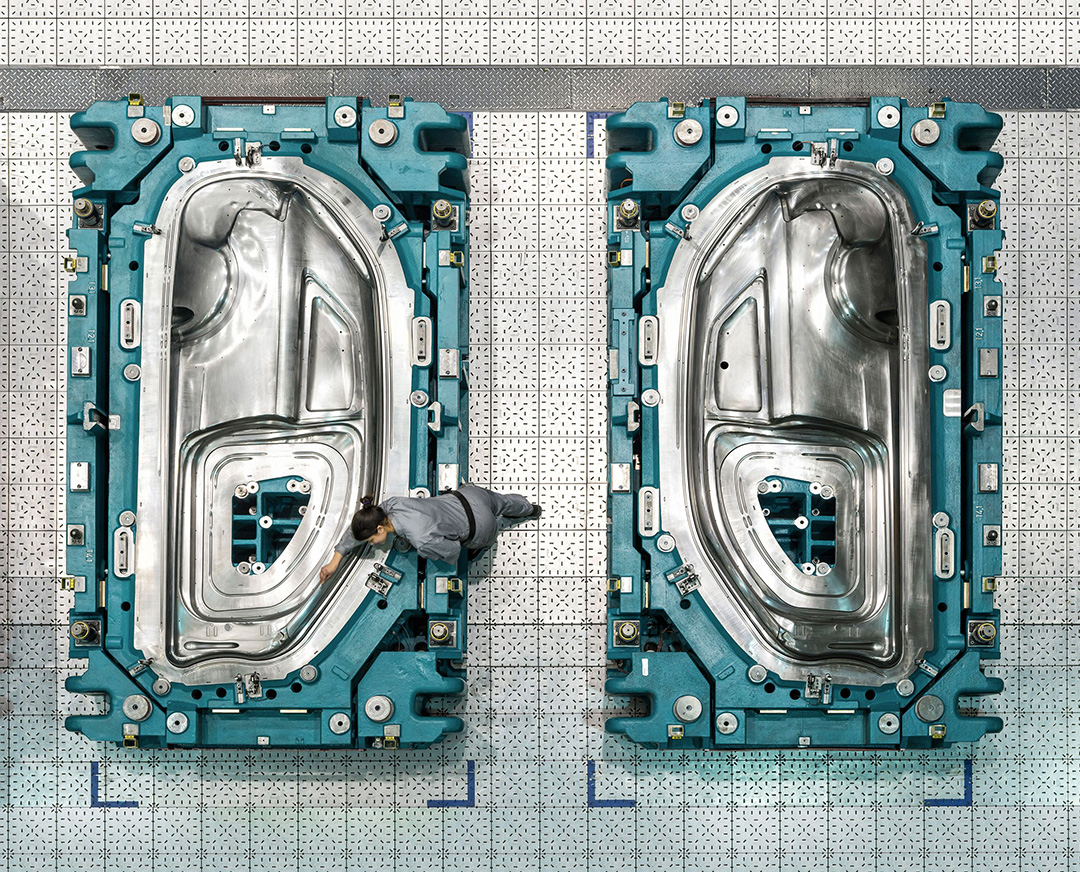

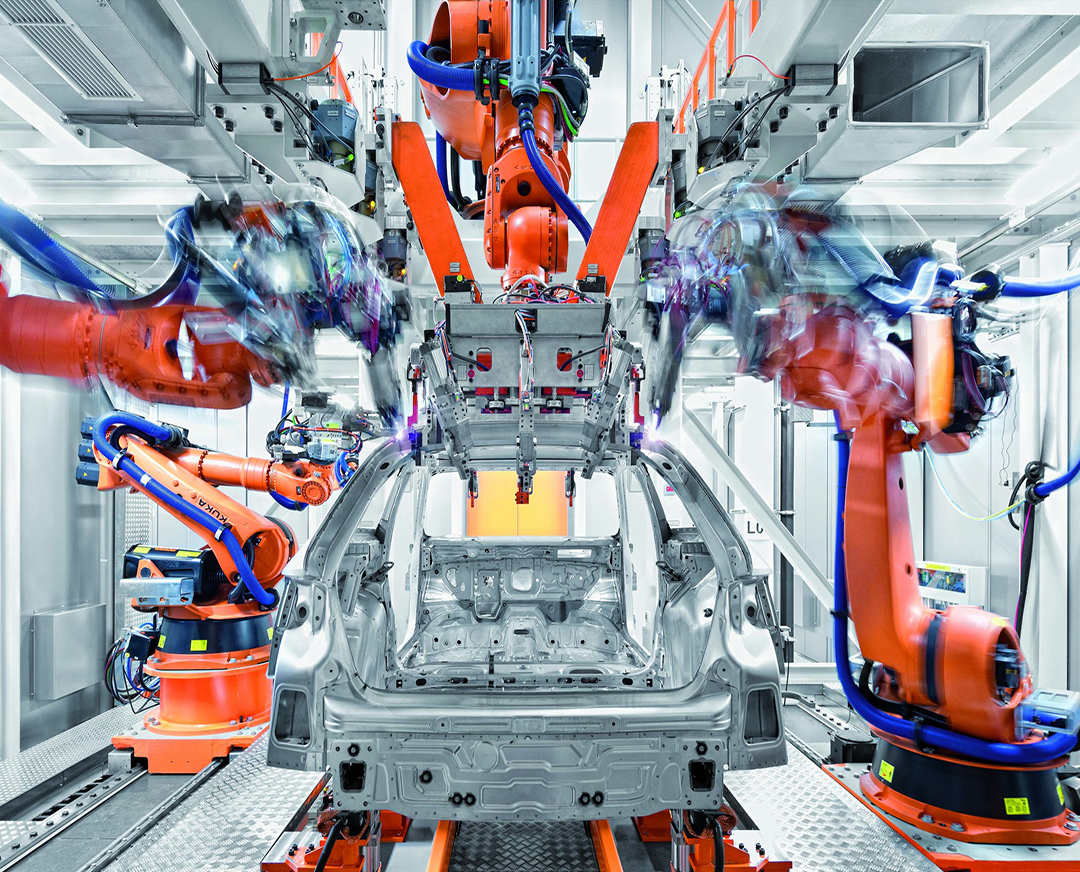

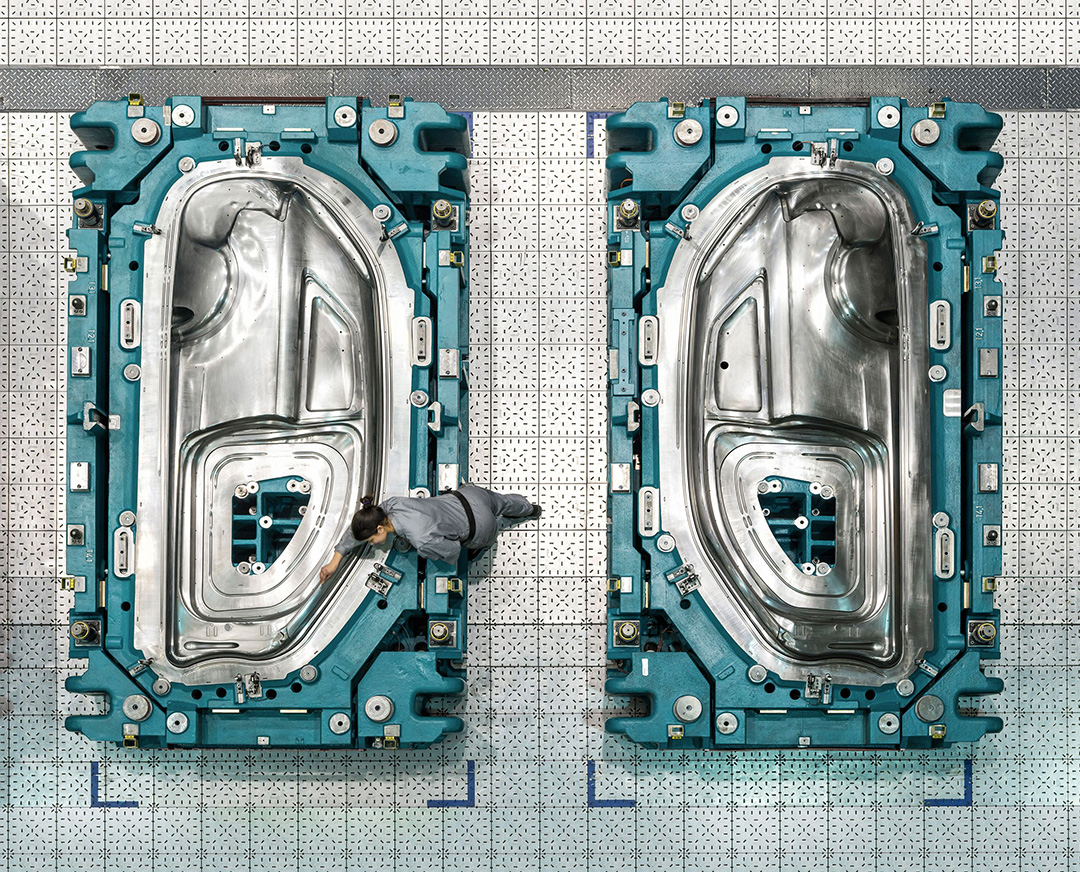

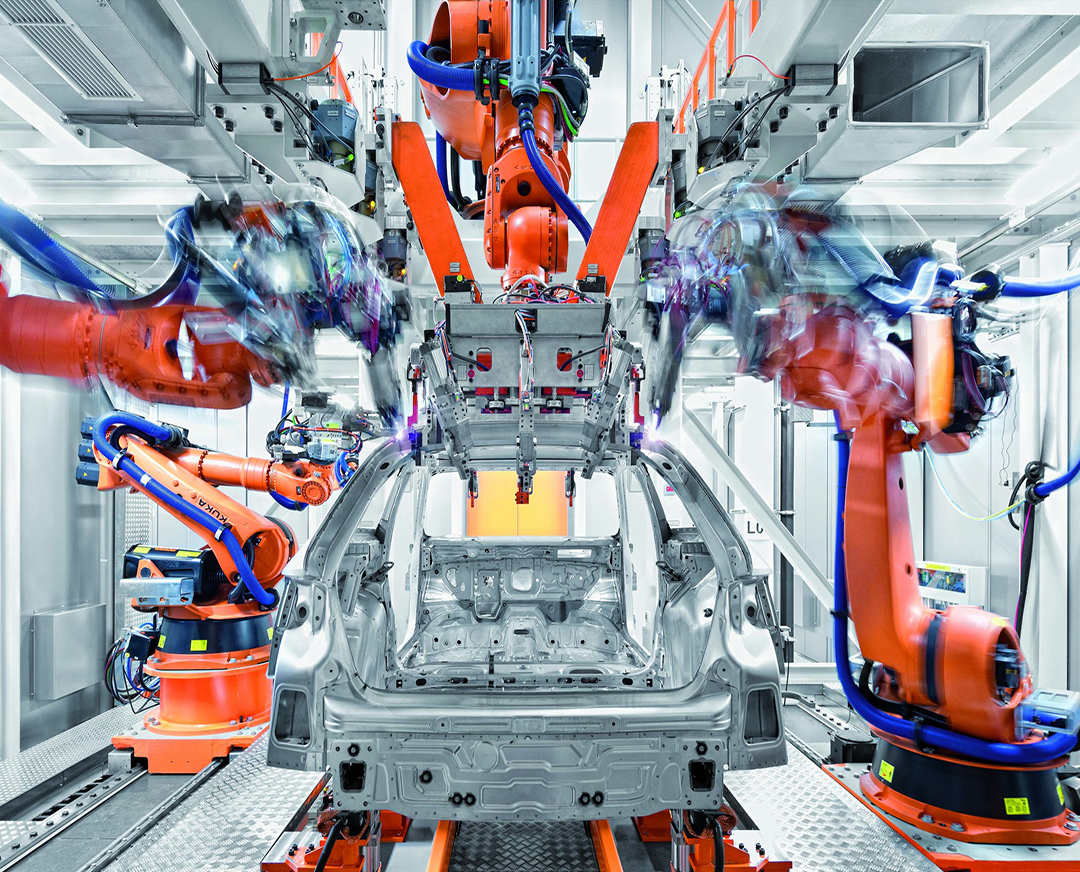

The toolmaking department at Audi AG (officially known since 2017 as the“competence centre for plant equipment and forming technology”or“KCU”)has always been one of the core competences of Audi AG. It is in charge of press tools for components such as vehicle doors, engine bonnets and side panels, as well as plants for building chassis. Driven to deploy external service providers by international competition, the people in charge are constantly on the lookout for innovations to improve processes and results.

奥迪公司的制造部门已成为奥迪的核心竞争力部门之一(从2017年以来,凭借先进的车间设备、成型技术和数控技术,奥迪制造部门成为最具有竞争力的部门),该部门负责制造各种冲压模具,例如车门、引擎盖、侧板和设备底盘。在具有国际竞争力的外部服务供应商的协助下,奥迪制造部门员工持续创新,提高加工效率和加工品质。

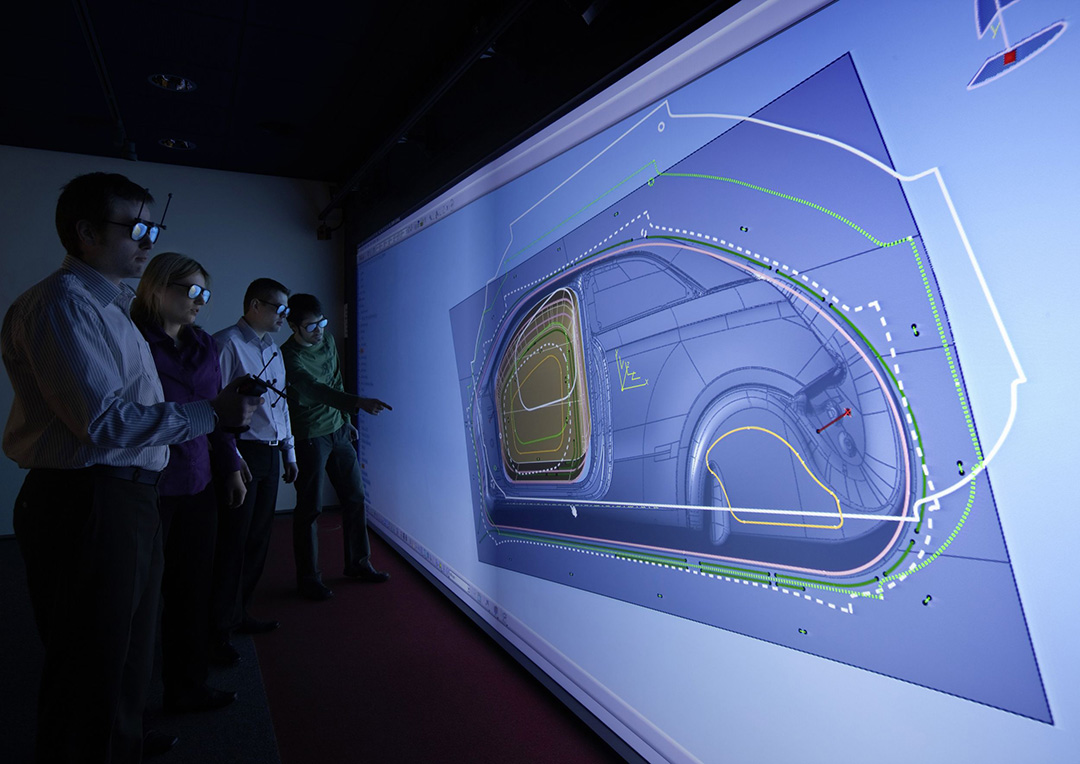

One such person who deals with innovations on a daily basis is Markus Brunner, a member of the Machine Technology Management team at the KCU in Ingolstadt. One of his tasks is optimising the toolmaking cutting production in terms of CAD and CAM technology.

“Single-part machining is one of the challenges we are confronted with here, and it gives rise to special requirements,”he explains.“Above all, frequent product changes necessitate high flexibility in machining. Efficient CAM programming is also very important in this regard.

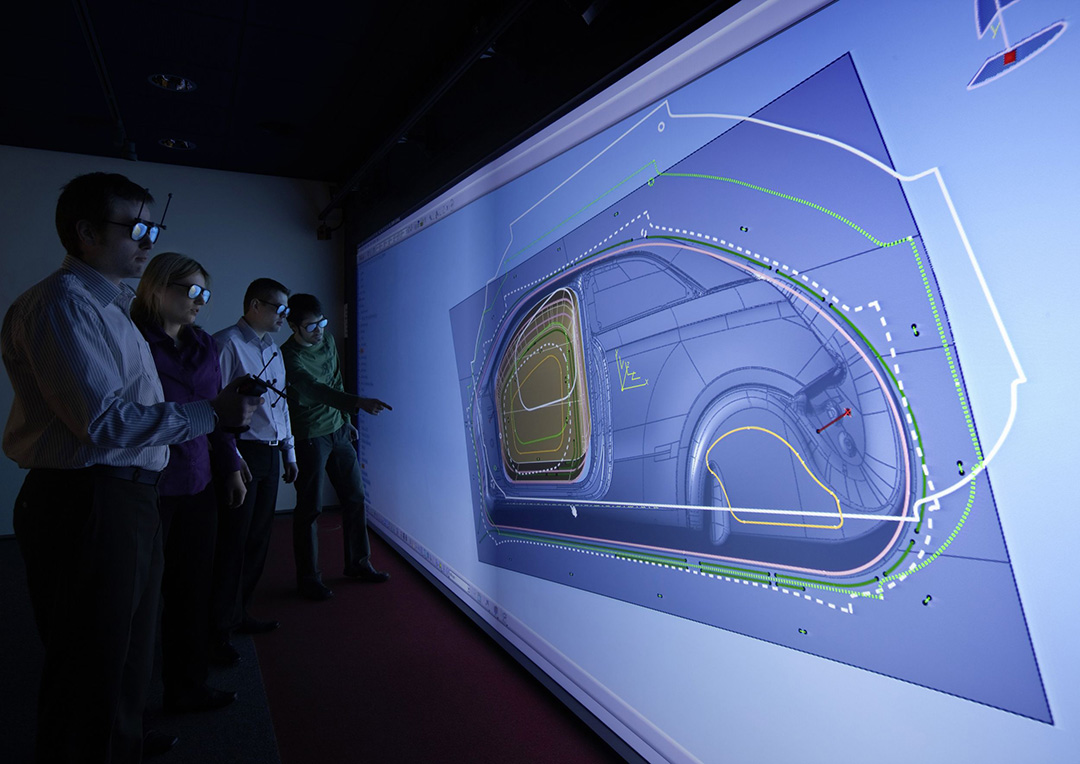

Markus Brunner is primarily occupied with increasing processing quality and throughput times with the use of modern, CAM-programmed machining technologies, thus reducing processing costs. His partner in programming software is Vero Software GmbH, with its WorkNC CAM system, which Audi Toolmaking has been using for many years now.“We continuously use WorkNCfrom 3 and 3+2 axis to 5-axis simultaneous milling of forming tools, and increasingly 2.5D processing as well,”Markus Brunner explains.

“WorkNC is extremely easy to program and handle, which is especially important in single part machining. It allows us to do the programming for even highly complex parts in a quick and intuitive manner. WorkNCalso offers many ways of standardising and automating machining tasks and the programming for them, in spite of single part production.”He also describes the processing strategies which WorkNC offers as“versatile and efficient,”as they make it possible to“program and process every component in a cost-effective manner.”

位于德国Ingolstadt的KCU的机械技术管理团队中, Markus Brunner主要负责日常工艺创新,其中的一项工作职责是优化模具加工生产方面的CAD/CAM技术。

他解释说:“单件的零件加工是我们面临的挑战之一,它会有一些特殊的要求。首先,频繁的产品变化需要加工的高度灵活性。在这方面,高效的CAM编程显得尤为重要”。

Markus Brunner主要忙于通过CAM编程技术,基于现代的加工时间提高加工质量,降低加工成本。他在编程软件领域的合作伙伴是Vero软件公司的WorkNC CAM系统,奥迪模具已使用WorkNC很多年了。“我们持续使用WorkNC的3轴、3 + 2轴、以及联动5轴铣削加工,现在也越来越多的使用WorkNC进行2.5D加工”,Markus Brunner解释说。

“WorkNC操作极其简单,尤其用于零部件加工。WorkNC能够使我们有效提高复杂零部件加工效率。除此之外,WorkNC提供多种标准化和自动化的加工策略 。”他把WorkNC的加工策略描述为“多样且高效”,帮助他们实现低成本,高效编程及高效加工。

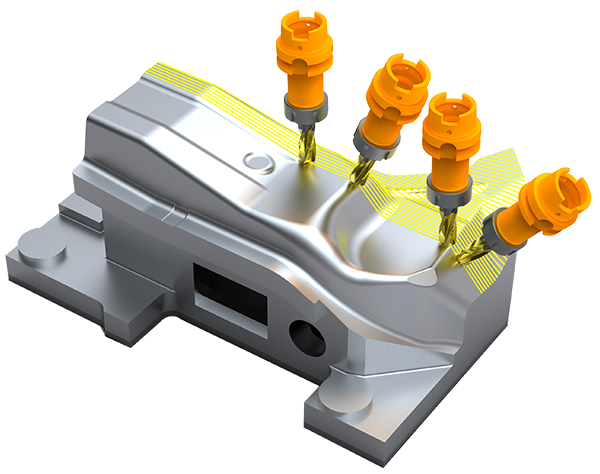

Vero is constantly refining WorkNC software in order to make milling work even more efficient in the future. For instance, the current release includes a new high-feed strategy which was proposed by the toolmakers at Audi and created in a close and partner-like co-operative effort.

为了提高铣加工效率,Vero不断改善WorkNC功能。比如,WorkNC最新发行版本中增加了由奥迪制造部门提出的新的高进给速率策略,这也为双方创造了一个紧密、互赢的合作关系。

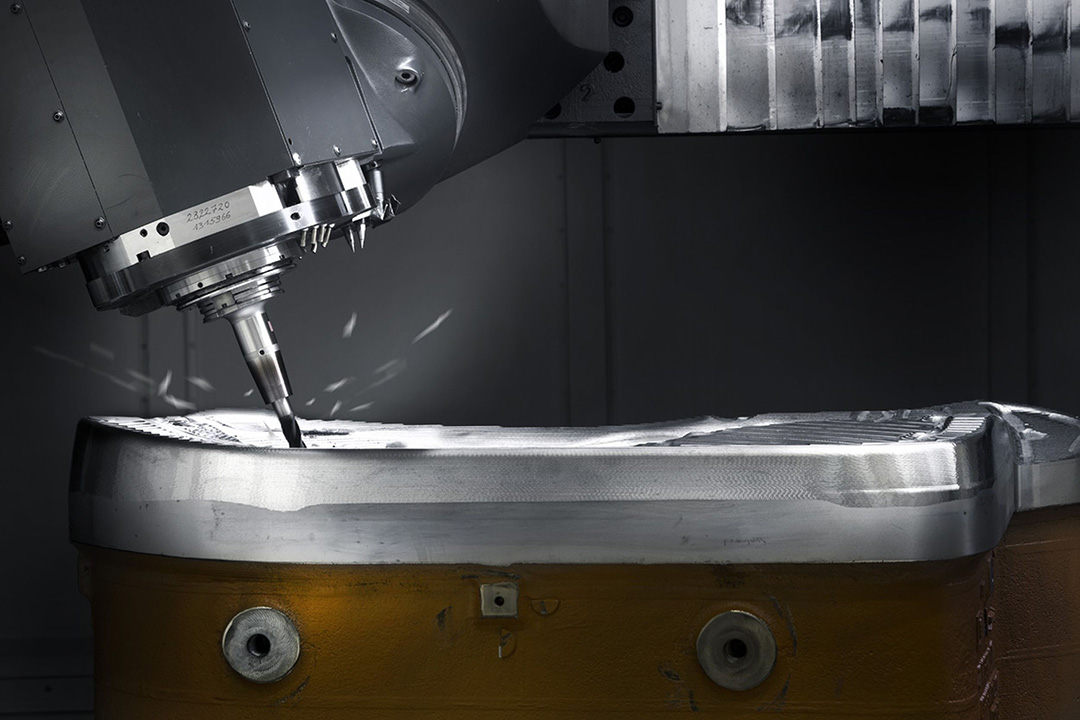

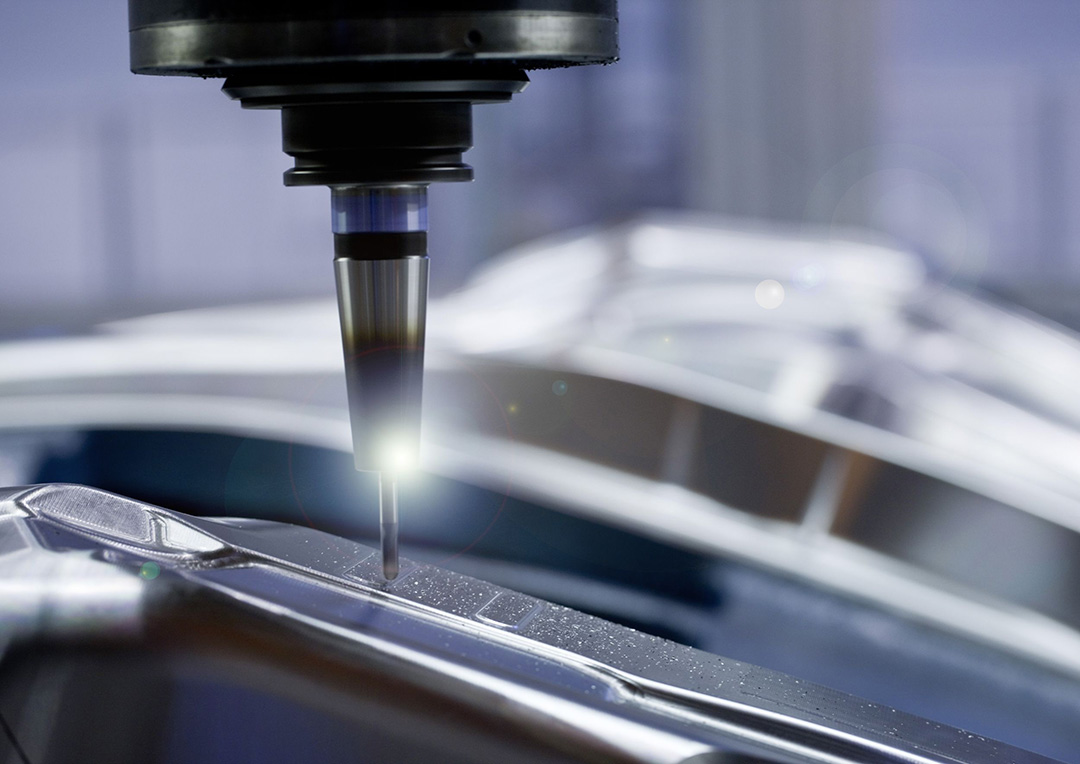

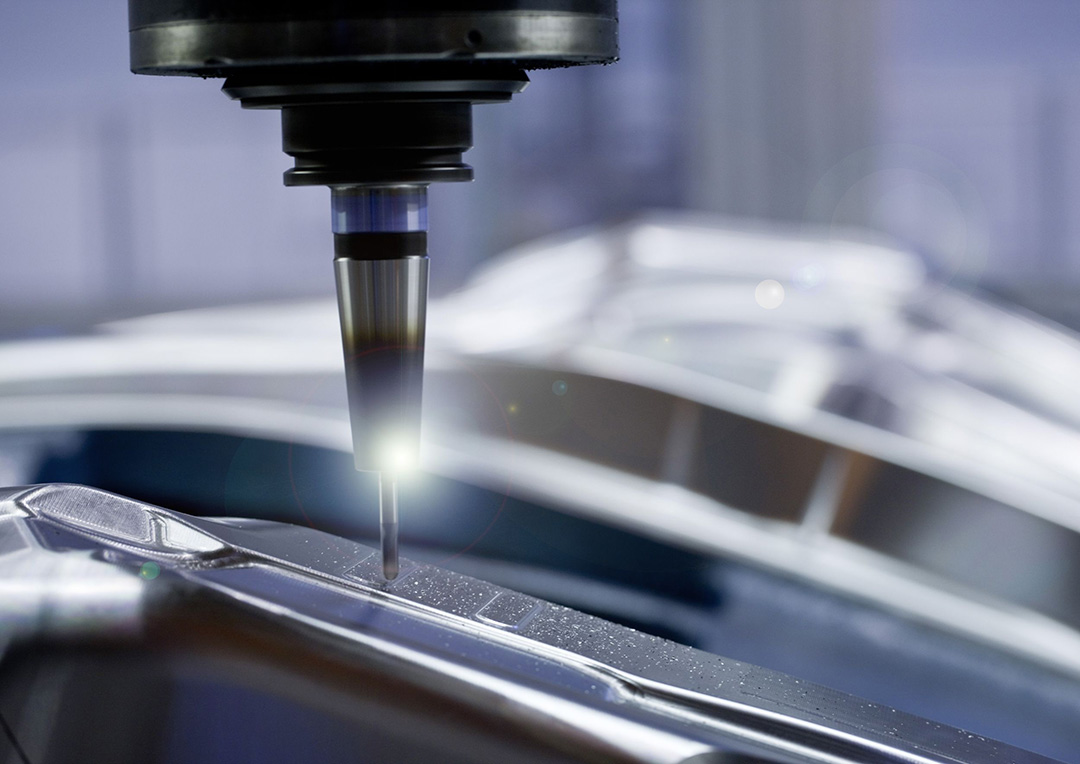

While high-speed cutting (HSC) primarily involves creating high-quality surfaces, high-feed cutting (HFC) provides short processing times in roughing and pre-finishing. Various suppliers have developed special tools with high-feed geometries for this purpose, with cutting edges that have a much larger line of contact with the workpiece than conventional round inserts.

This reduces the radial cutting force load on the mill and the machine spindle so much as to allow significantly higher tooth feeds and increase the metal removal rate many times over. This is especially advantageous for reducing processing time and production costs in roughing and pre-finishing work with intensive cutting.

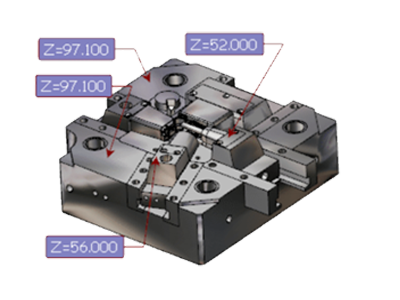

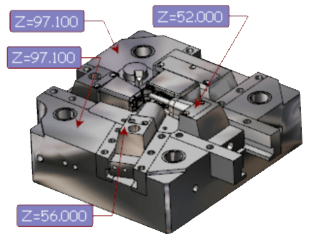

Before Vero presented its new WorkNC solution, the users found themselves confronted with the following problem when using these tools: Up till then, CAM systems were not able to sufficiently reproduce the new high-feed geometries, which led to an undefined allowance on the component surface. This, in turn, impaired processing reliability in the downstream finishing process.

The new high-feed strategy now factors in deviations in milling tool geometries with irregular cutters. WorkNC thus prevents undefined allowances from appearing on the workpiece. Markus Brunner is enthusiastic about the result:“This new strategy enables us to use milling tools of any contour, even ones with cutters which deviate from a regular geometry such as a sphere or torus. This even allows us to use milling tools which were specifically designed for a defined application case.”

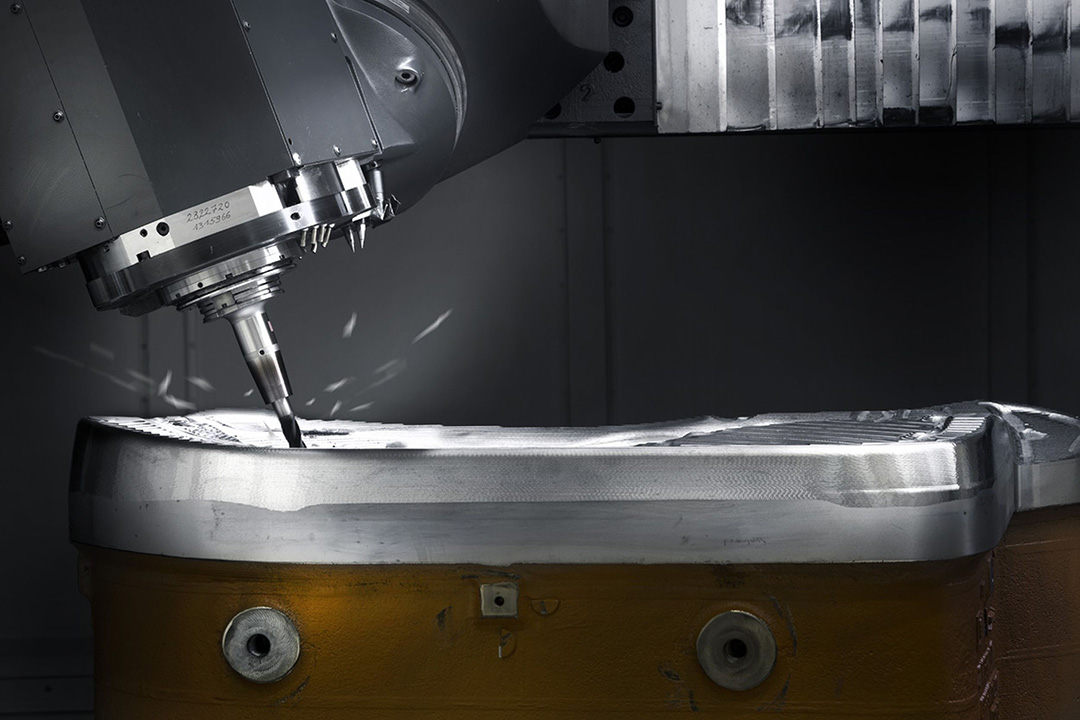

His enthusiasm doesn’t come from nowhere. After all, Brunner and his colleagues were the driving force behind the new development. They also provided machine capacities for testing purposes. For instance,they cut the negative surface offset of a press tool for a car door. Whereas pre-finishing work for the outer door panel used to take three hours and 15 minutes, and the cutting inserts had to be changed three times, processing with the new WorkNC high-feed strategy only took one hour and 42 minutes–without having tochange any inserts. The tool used was a 1DP1E high-feed mill from Ingersoll Cutting Tools (WSP type PEMT0502ZCTR-HR, WSP quality IN2505; 65 mm projection length).

高速切削(HSC)主要包括提高加工表面品质,而高进给切削(HFC)在粗加工和精加工过程中缩短了加工时间。为此,刀具供应商们开发了很多专用于高进给切削的几何形状异形刀具,异形刀的切削刃与工件之间的接触面比传统的圆刀片要大得多。

这减少了径向切削力对机床及主轴头的载荷,提高了切削进给量的同时提升了金属去除率,这对于减少粗加工和半精加工的时间及节约生产成本特别有益。

在Vero发布新的WorkNC策略之前,很多用户发现,当他们使用异形刀具时,他们会发现这些问题:直到那时,CAM系统还不能充分地显现新的高进给几何形状刀具,从而导致切削时无法定义工件表面残留量,相应地又损害了下游加工过程的加工可靠性,破坏了精加工品质。

现在,WorkNC新的高速进给策略能够适用于异形刀具,能够精准地定义工件残留量。有效提高加工效率和工件表面质量。 Markus Brunner对于这个结果非常兴奋:“WorkNC新的策略能够使我们使用各种形状的铣刀,如偏离常规的几何形状,如球面或环面刀具,甚至允许我们使用专为特定应用程序设计的铣削异形工具。”

Brunner如此兴奋是有原因的。毕竟,布鲁纳和他的同事是新发展的驱动力。他们还提供测试机器能力。比如,他们为汽车车门冲压模具进行精加工。然而,外车门半精加工通常需要3小时15分钟,需要进行3次刀具装夹。而使用WorkNC新的高速进给策略,只需1小时42分钟,且一次刀具装夹就可完成整个加工。(所用的刀具是由英格索尔刀具公司提供,刀具型号:PEMT0502ZCTR-HR,切削增量:63627mm/min,切深:65mm )

“By using WorkNC’s high-feed strategy and the tools to match, we have reduced processing time in pre-finishing work by up to 30 percent,”says Markus Brunner. The driftingforces are lower than those with round insert cutters, which contributes to longer tool life.Since the main machining forces arise in the Z-direction (i.e. the spindle direction), vibrations are reduced and the tool generally runs more quietly, which has a positive effect on the cutting process.

“The new WorkNC strategy can also be used with negative surface offset,which I believe is not possible with any other CAM supplier at present. In the future, we will definitely be using it with all components in the pre-finishing processing step.”

“通过使用WorkNC新的高速进给策略和匹配刀具,我们半精加工效率提高了30%,”Markus Brunner说,“与球形刀具相比,切削力更均匀,有助于延长刀具寿命。当Z轴切削力量增加时,减少震动、刀具运行更加平稳 、有效提高加工品质。”

WorkNC新的高速进给策略能设置加工负余量。我相信目前除了WorkNC,没有任何一款软件可以做到。未来,我们一定会把他用在制作不同工件的所有半精加工步骤中。

To the Audi team, the new high-feed strategy is an example of the productive, partnership with Vero and the WorkNC developers. However, their satisfaction extended to a great many other aspects:“WorkNC’s options for subsequently modifying programmed milling paths, such as offsetting and cutting paths, are extremely important to us.”He is also impressed with the short calculation times, thanks to 64 bit and multiprocessor technology, which he says is very important, especially when programming large parts.

“The flexibility of the overall system is also much appreciated. For instance, WorkNC’s post-processors are not encrypted, and can be adjusted by the user at any time. This has enabled us to significantly increasethe level of automation in our single-part production over the past few years.”In addition, this allows it to quickly adjust the CAM output to the increasingly complex machine technology, so as to exploit the full potential of the tool machines.

对于奥迪的团队,WorNC新的高速进给策略生产是一个于Vero及WorkNC开发商友好合作的成功案例。奥迪还对WorkNC很多方面都非常满意:“WorkNC能够修改已经编好的切削路径。例如,补偿路径切削量 ,这对我们极其重要。”他对WorkNC快速的计算速度大为赞赏,多亏了64位多重处理器技术,尤其在计算大工件的时候特别重要。

“感谢WorkNC整个系统的的灵活性。比如,开放的后置处理器,用户任何时候都可以修改。在过去几年中,WorkNC显著提高了我们零部件加工的自动化水平。”除此之外,WorkNC能够快速应对不断发展的加工技术,从而帮助我们充分挖掘加工设备的全部潜能。”

|

WorkNC

WorkNC