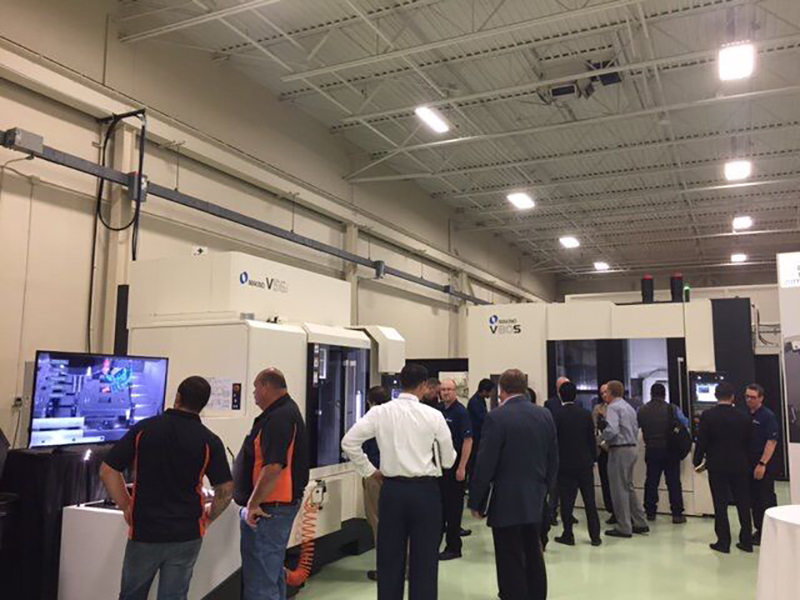

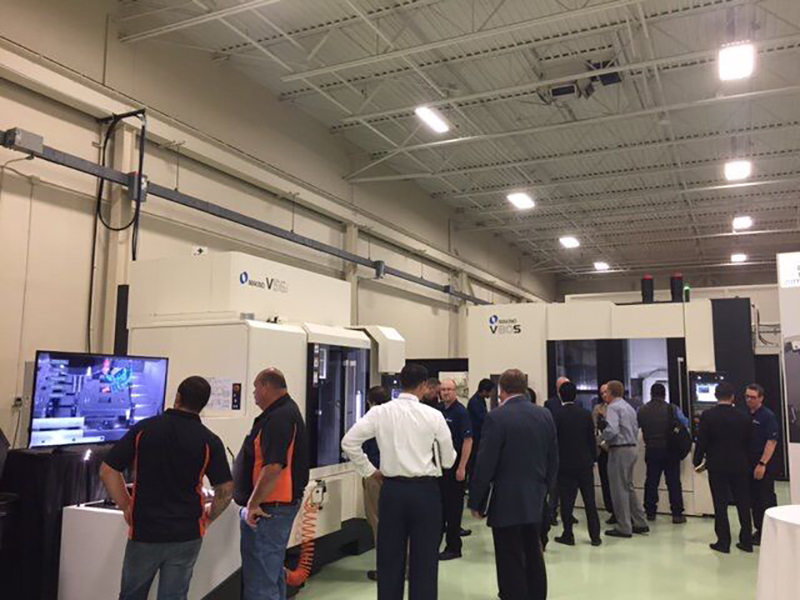

The latest release of WorkNC, by Vero Software, will be featured Sept.13-14 at the Makino Die/Mold Technology Expo, hosted at Makino’s Die/Mold and EDM Technology Center in Auburn Hills, Mich.

2017年9月13-14日,Vero Software旗下的WorkNC最新版在美国密歇根州奥本希尔斯的牧野模具和电火花技术中心举办的牧野模具技术博览会上展出。

The Makino Die/Mold Technology Expo is a biennial exhibition that highlights new and improved manufacturing processes, techniques, philosophies and strategies vital to transforming businesses for greater success in the global marketplace.

牧野模具技术博览会是两年一次的展览,展览会展示了新的改进的制造流程、技术、原理及策略,使企业在全球市场取得更大的成功至关重要。

The event will include demonstrations of some of Makino’s latest high-precision machining technologies,including machines equipped with the new Professional 6 (Pro6) control, updated sinker EDM technologies with the new Hyper-i control, the recently released D200Z 5-axis vertical machining center, and an all-new high-precision 5-axis vertical machining to be unveiled on the show floor. More than 23 machines are going to be powered up, with multiple demonstrations displaying state-of-the-art machining process solutions.

此次活动将演示牧野的部分最新高精度加工技术的,包括配备新的专业6(Pro6)控制的机器、新的Hyper-i控制的新EDM技术,最近发布的D200Z5轴立式加工中心,以及全新的高精度5轴立式加工中心在展会现场亮相。本次展览有超过23台设备多次加工展示了最先进的加工工艺解决方案。

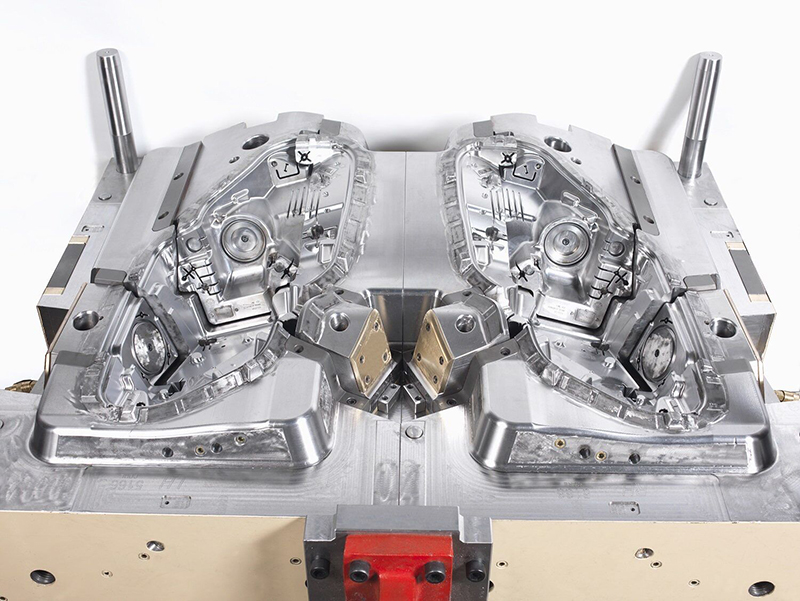

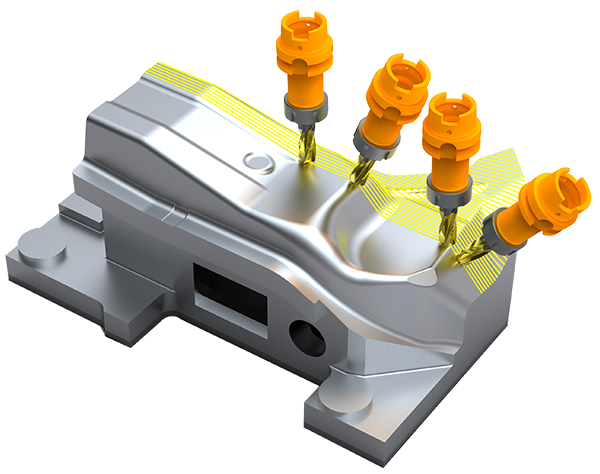

WorkNC’s new Parallel Finishing toolpath makes use of innovative Advanced Toolform technology, which offers efficient high-feed cutter management.Toolpath calculations are based on the real shape of the cutter,which ensures optimal surface quality and machining times reduced by up to 80 percent.

WorkNC新的平行精加工Parallel Finishing toolpath利用创新的高级Toolform技术,提供了高效进给的切削管理,刀具路径计算基于刀具的真实形状,确保最佳的表面质量,使得加工时间减少高达80%。

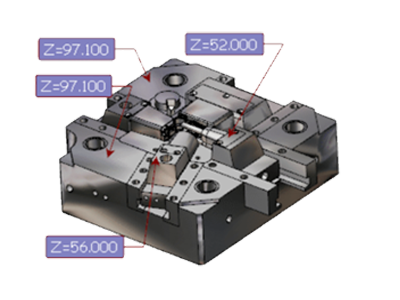

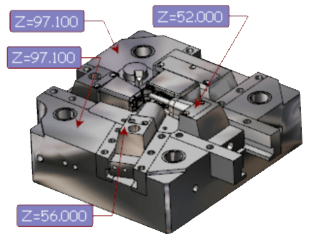

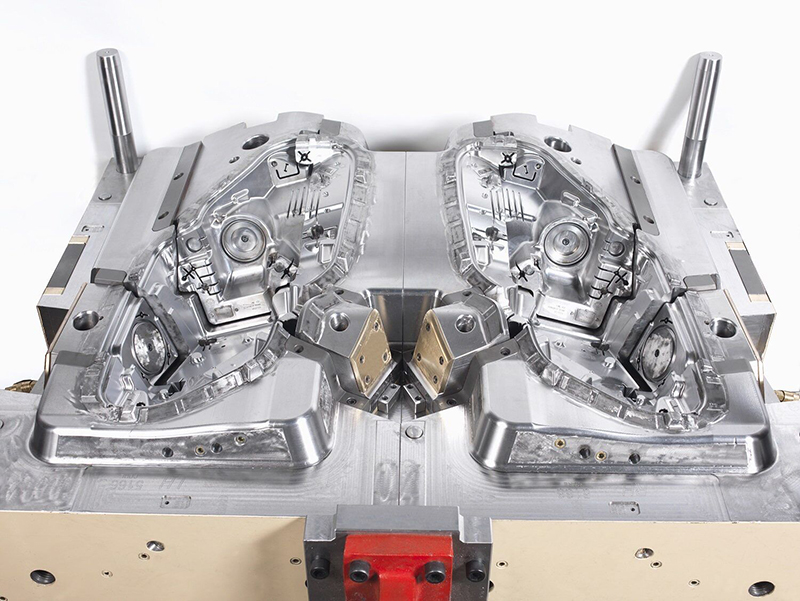

This latest release of WorkNC automates and simplifies the Machining Sequence process, delivering step-by-step assistance during toolpath programming. The Machining Sequence process now informs the user of any missing data in the Workzone, such as views, curves, point, etc.,allowing for last-minute corrections.

最新版的WorkNC自动简化了加工顺序过程,在刀路编程期间提供分步帮助。在处理序列过程中实时提示用户工作区中的任何丢失的数据,例如视图、曲线、点等,允许最后一分钟进行更正。在中国,牧野机床受到众多企业的喜爱,在做复杂及精密件加工时,很多选购牧野机床的公司选择了编程软件WorkNC进行配套加工,如(小糸车灯、歌尔、海信、星宇车灯、赫比、汇众、待确定)。WorkNC在牧野机床上的应用,使用户获得极佳品质的同时,大提高了生产效率。

WorkNC&Makino加工Chrono手表视频:

○关于WorkNC ○

WorkNC CAM software isthe premier automatic CNC software for surface or solid models in mold, die andtooling businesses for 2 to 5-axis CNC programming. Allwestern, Japanese, and Korean automotive makers, and well-known OEMs from arange of other industries, use WorkNC.

WorkNC CAM软件是世界领先的高效自动化2-5轴CNC编程软件,所有西方发达国家、日韩国、中国等汽车制造商以及其他行业的知名OEM厂商都在使用WorkNC。

更多WorkNC信息,请关注WorkNC微信公众号:qh_worknc;访问强互官网:http://www.qianghu.com/

WorkNC技术问题,欢迎在WorkNC技术论坛交流,全国最强的WorkNC技术工程师在线与你互动:http://www.qianghu.com/bbs

数控设备与WorkNC战略合作热线:

13651990564

|

WorkNC

WorkNC