机床:

|

Hermle 哈墨

|

品牌及型号:

|

Hermle 哈墨 C32U

|

加工材质:

|

AlMgCuPb aluminium 等

|

行业类型:

|

汽车行业赛车轮架模型等

|

刀具:

|

Ingersoll 英格索尔

|

装夹:

|

Gressel 格里塞

|

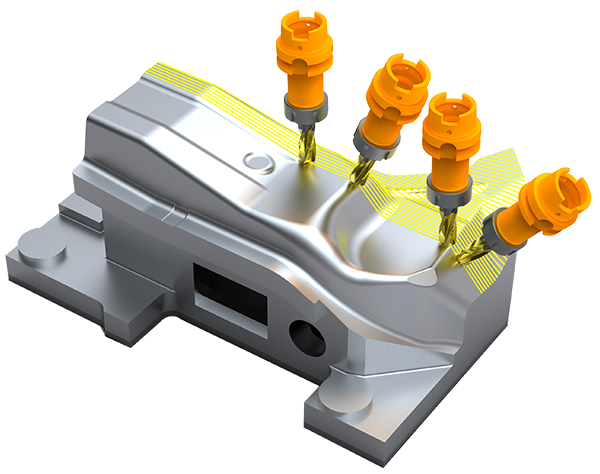

WorkNC partnered with Hermle, Ingersoll and Gressel to provide a one-stop machining solution for a motorsport prototype wheel carrier.

WorkNC与Hermle、Ingersoll 、Gressel 合作为赛车模型轮架制造商提供一站式加工解决方案。

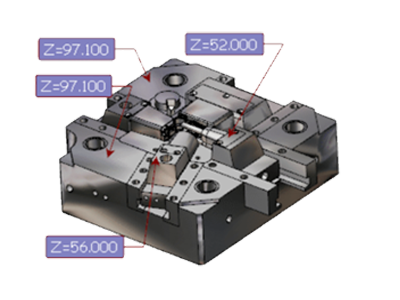

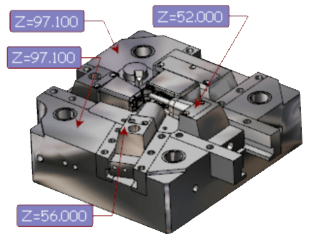

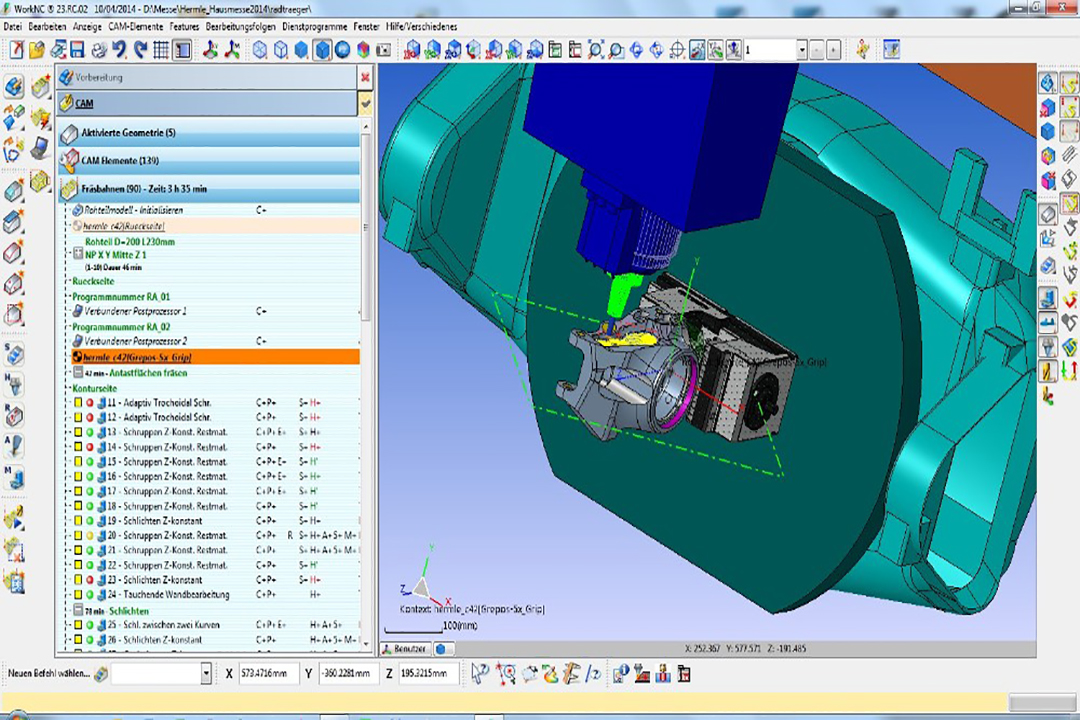

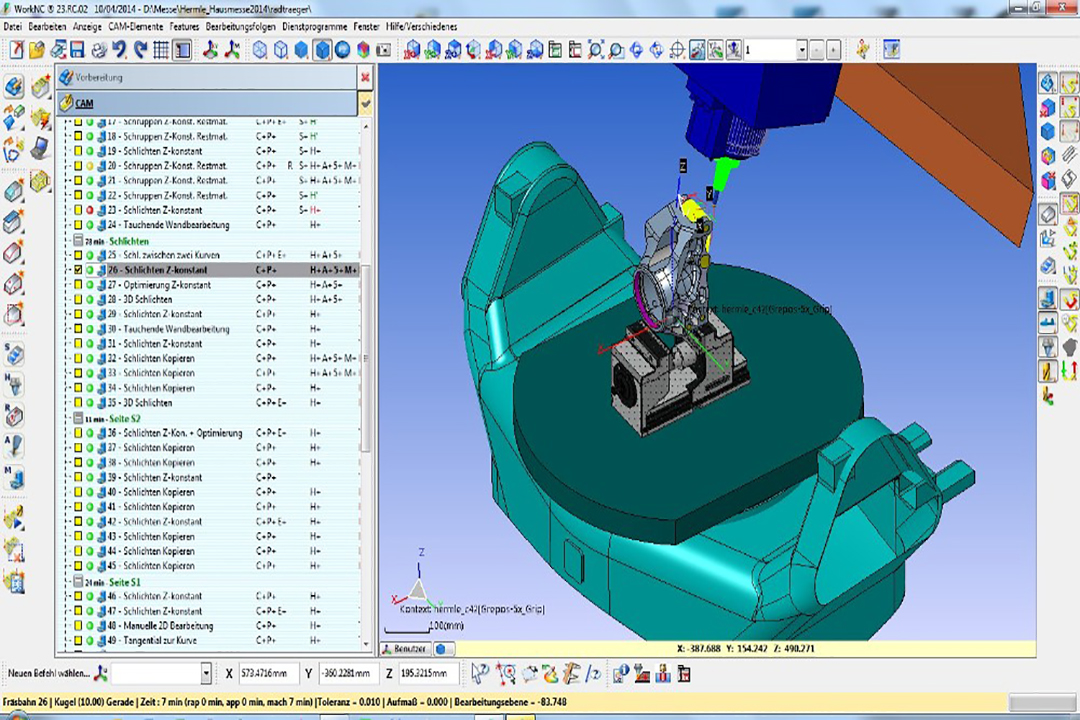

Utilising WorkNC’s diverse 2D, 3D and 5-axis toolpaths, the wheel carrier was machined from AlMgCuPb aluminium using adaptive trochoidal roughing and global re-roughing strategies and finished largely with 3+2 axes.

AlMgCuPb铝制轮架加工时,利用了WorkNC丰富的2轴、3轴 和5轴加工策略,其中包括可调节的摆线粗加工和全局再粗加工策略,并由3+2轴完成主要精加工。

It was carried out on a Hermle C32U machine, with the stock held in place by a Gressel workholding system. The Ingersoll cutting tools included FormMaster pro for the pre- roughing and machining of the back of the carrier, ChipSurfer for re-roughing, OctoPlus for facing, ChipSurfer Ball for contour finishing, and a variety of tools for drilling, tapping and boring.

由WorkNC配置于安装Gressel装夹系统的Hermle C32U加工中心合作完成整个加工过程。其中利用的Ingersoll 刀具包括用于轮架背部开粗的FormMaster,用于二次开粗的ChipSurfer,用于表面加工的OctoPlusr,用于轮廓精加工的ChipSurfer球刀,以及多种用于钻孔、攻螺纹和镗孔的刀具。

Gerhard Hermann, Sales Engineer at WorkNC, says the partnership shows co-ordinated teamwork in the manufacturing chain between machine tools, cutting tools, workholding and CAM software. “We have worked together on many occasions in the past few years. This wheel carrier for a racing car is a perfect example of how a proven, single source solution ensures manufacturers can optimise their machining process.”

WorkNC销售工程师Gerhard Hermann表示,该合作关系展示了加工中心、刀具 、夹具 以及CAM软件制造链之间的协调合作。“过去几年中,WorkNC和Hermle, Ingersoll and Gressel一直密切合作。而此次合作加工的赛车模型轮架完美证明了一个成熟的一站式解决方案能够确保制造商最大程度优化加工过程。”

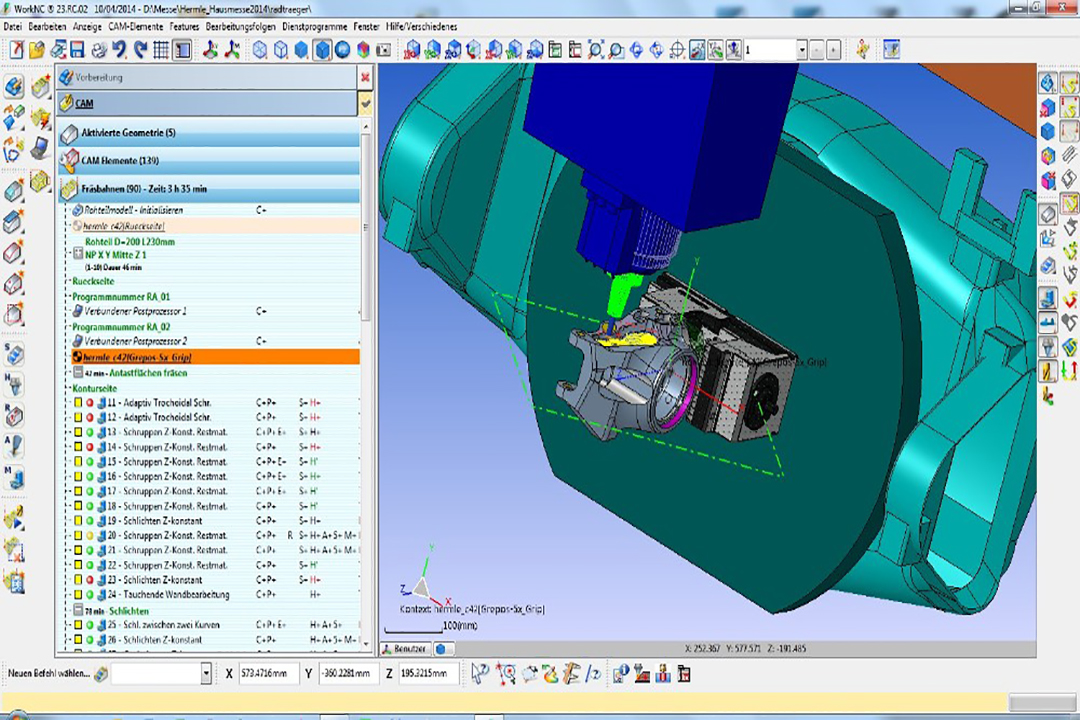

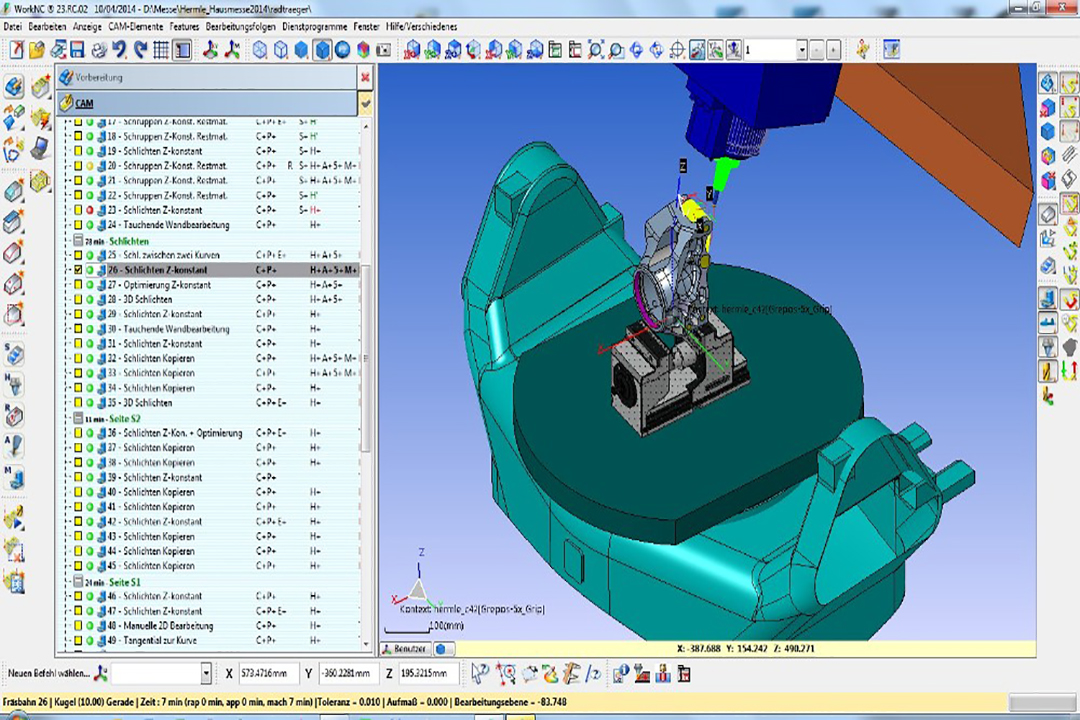

In producing the wheel carrier WorkNC automatically considered the tool holder during calculation, to obtain optimal machining of all areas. “This was achieved principally through the use of a dynamically updated stock model,” says Gerhard Hermann. “Due to exact information about the current state of machining, only areas with remaining stock were milled. WorkNC automatically separated those 3-axis toolpaths into several inclined 3+2-axis paths. The angles can either be set by the user or defined in a very simple way using the Auto 3+2 module, reducing programming to just a few clicks.”

轮架加工时,WorkNC在计算过程中自动考虑夹具,获得所有区域的最佳加工效果。“这主要通过使用动态更新储存模型实现,”Gerhard Hermann说,“根据当前加工状态的准确信息,只铣削模型剩余未加工区域 。WorkNC 自动将那些3轴刀路分成几条不同角度的3+2轴刀路。这些角度可以由用户重新设置或通过Auto5模块轻松进行定义,减少编程时间。”

In addition,WorkNC’s 5-axis simultaneous milling generates continuous toolpaths, creating an excfellent surface finish with short tools. “Programming is considerably simpler as only a few toolpaths need to be defined.”

除此之外,WorkNC5轴同步铣削可生成连续性刀路,通过短刀具生成优质表面。“WorkNC编程要简单很多,只需要定义好几条刀路即可。”

Each WorkNC toolpath can be automatically converted into a collision-free 5-axis path, meaning there is no need for time-consuming definition of guide curves or surfaces.

WorkNC的每一条刀路都能自动转化为安全可靠的5轴刀路,这意味着不需要费时费力去定义是曲线还是曲面。

WorkNC可应用于各行各业的数控加工领域,可与市面所有的数控铣床无缝对接,最大程度地发挥机床的潜能,保障加工高效高质高安全。不论是什么品牌的机床,进口机还是国产机、不同的机床系统(西门子、发那科、海德汉、三菱、CAXA还是各种机床自带的特殊系统等)、不同的材质如钛合金、铝、镁、锌、钢、尼龙、油泥、木材、塑胶、硅胶、亚克力等等,都可配套WorkNC进行加工编程。

资料来源:WorkNC用户和哈墨、英格索尔、格里塞网站

WorkNC

WorkNC