Roughing operations take half the time to program and run 70% faster.

——Roy Thomas, Patterson Mold & Tool

Direct machining of the die has eliminated EDM operations resulting in a dramatic 82% reduction in manufacturing time.

——Hiroki Takama, Riken Forge

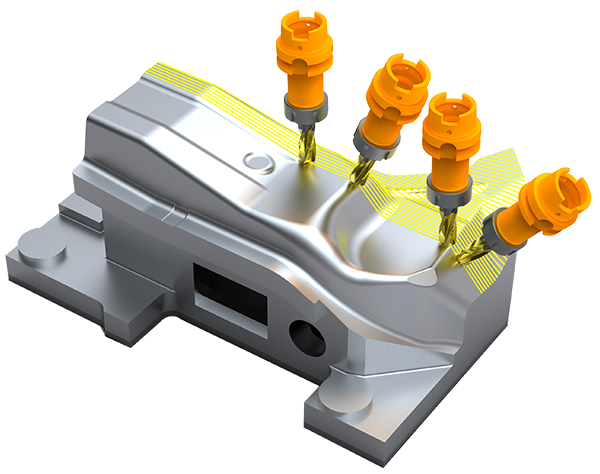

WorkNC allows us to machine successfully with 0.2mm diameter tools 10.5mm long, which is a length to diameter ratio of 26, without deflection or damage.

——Mr Kazuya Fukushima, Shinkoh Mold Co. Ltd

On the new complex milling programs we are working with, WorkNC’s simulation ensures a high level of security for the whole machining process.

——Thorsten Koch, Meissner AG

WorkNC’s graphic toolpath editor is lightning fast.

——Ceyhun ÇINAR, Serdar Plastik

Four modellers in the Styling Studio use WorkNC in the workshop. Its ease of use makes their tasks much simpler and they have absolute confidence in the results it produces.

——Kevin Baker, Bentley Motors

The analysis function color codes radii so we can select the right tools from the tool library, and the dynamic cross section and semi-transparent part views make it easy for us

to examine complex components.

——Haruki Matsui, TOMCO Co Ltd

WorkNC’s parallel processing is a quantum leap in performance.

——John Harvey, Harvey Precision

I was totally amazed at how easy it was to learn. Additionally, we get regular visits from WorkNC engineers and we take full advantage of extra training opportunities.

——Marvin Sims, Presrite Corporation

The benefit of WorkNC to Prospect Mold is phenomenal, we monitor our machine utilization levels and we consistently spend 80% of our time cutting metal.

——Mark Gruic,Prospect Mold

The 3D stock model feature is a very useful option for us. Being able to rough the part out, and then go back in with smaller tools, helps us to remove as much material as possible before finishing.

——Jason West,Astro Machine Works

Once machining is complete the tooling component is practically finished, as WorkNC’s rapid and reliable finishing toolpaths give a remarkably high surface quality. The parts require very little manual reworking.

——Michel Gauthier, Bemap Aranda

We used WorkNC’s machining strategies for roughing and finishing and the result was remarkable. Using the same parameters as we had on our old CAM system, WorkNC solved our problems easily, producing smooth curves without any ripples or stripes, and a much brighter and higher quality surface finish straight off the machine.

——Mr Liu, Shandong Weifang Foton Mould Co. Ltd

The benefit of WorkNC to Prospect Mold is phenomenal, we monitor our machine utilization levels and we consistently spend 80% of our time cutting metal.

——Mark Gruic,Prospect Mold

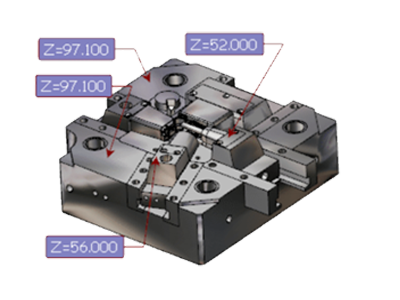

The return on investment from WorkNC Feature Recognition was immediate. Not only has it saved us many hours of work, it has also made our machine shop more productive and cut out many of the sources of error, greatly increasing the accuracy of our finished tools.

——Ed Busman, Walker Tool and Die

Automatic feature recognition will actually identify all of the holes, whether it’s a tapped hole, a drilled hole, hole, et cetera. That saves a lot of time.

——Joseph Batz, Sable Engineering

Machining productivity is up by 75% thanks to WorkNC. Machine down time has been eliminated and problems caused by inconsistent manufacturing methods, incorrect tooling and hole positioning errors are a thing of the past.

——Ron Francis,Walker Tool and Die

Ten years ago, when we would machine the cosmetic side of a component, it would take 24 hours, and now, we have it down to seven.

——Darren Wright,LB Mold

WorkNC is the best software we have for 3 and simultaneous 5 axis machining. Our engineers prefer it by far. It has definitely enabled us to win more business.

——Haruki Matsui, TOMCO Co Ltd

We use WorkNC’s Auto5 module exclusively for our 5 axis programming and we found it so easy to use that we did not need any training. Now around 25% of our work requires 5 axis machining and our 10 machinists use it every day in the workshop.

——Roy Thomas, Patterson Mold & Tool

了解更多详情,可以添加我们的微信号:qh_worknc

扫二维码:

WorkNC

WorkNC

赛科利评价

赛科利评价 通用评价

通用评价 海信评价

海信评价 长安马自达评价

长安马自达评价 宇通客车评价

宇通客车评价 北汽评价

北汽评价 河北金环评价

河北金环评价 中国中车评价

中国中车评价 柯尼卡美能达评价

柯尼卡美能达评价 上海大众评价

上海大众评价 上海小糸评价

上海小糸评价 上海汇众评价

上海汇众评价 沈阳宝马评价

沈阳宝马评价