As is the case with all manufacturers, time is of the essence for Andreas and Joseph Batz.The two experienced Michigan-based manufacturers of automotive, aerospace and medical parts are dedicated to turning out the best products in the business while cutting both programming and machining time.“We’re taking this to the next level and doing things that other people haven’t even thought of doing,” says Joe Batz, director of operations for Sable Engineering of Port Huron, Michigan.

Andreas 和 Joseph Bat如所有制造商一样,都认为时间至关重要。他们来自美国密歇根,在汽车、航空航天和医疗器械零部件加工方面拥有丰富的经验,长期致力于为用户提供最优质产品的同时,节省编程和加工时间。“我们正在提高这个水平,通过正在做一些其他人甚至还没有想到的事情,” Joe Batz说。他是位于密歇根休伦港Sable Engineering公司的运营总监。

Sable’s key strategy for taking business to the next level is investing in the kind of machinery and software that will empower them to reach the topmost rung of their enterprise. “We are striving to build state-of-the-art facilities,” says Andreas Batz, Sable’s president and founder, of what sets his company apart from the pack.

Sable提高业务水平的关键策略是投资那些能够让他们成为企业龙头老大的高品质加工设备和数控编程软件。“我们正在努力建造最先进的设备,”Sable公司总裁兼创始人Andreas Batz说,这能够让他的公司从同行业中脱颖而出。

Established partially for Andreas’s love of automotive engineering, the company has steadily grown since its founding in November of 1999. With 14 employees strong and still growing, Sable’ s star remains on the rise.

由于Andreas热爱汽车制造,所以自Sable建立以来就把其作为主要业务。Sable成立于1999年11月份,一直稳定发展。目前,Sable已拥有14名工程师,并仍在不断壮大中。Sable的明星工程师人数将会越来越多。

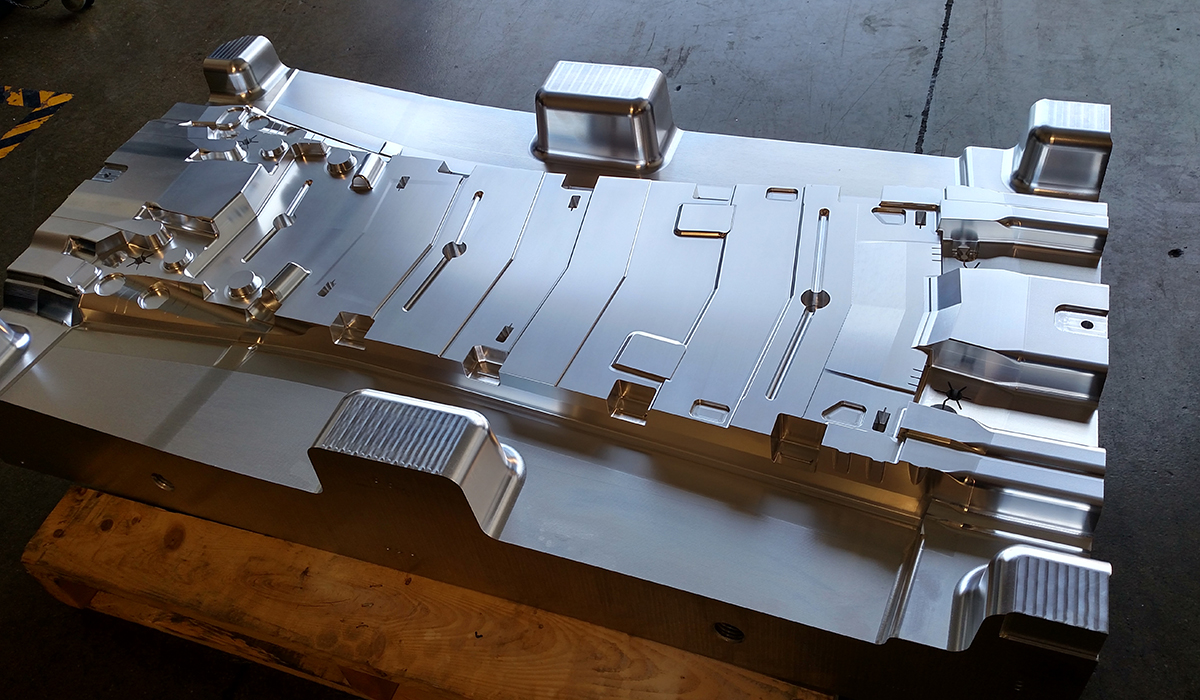

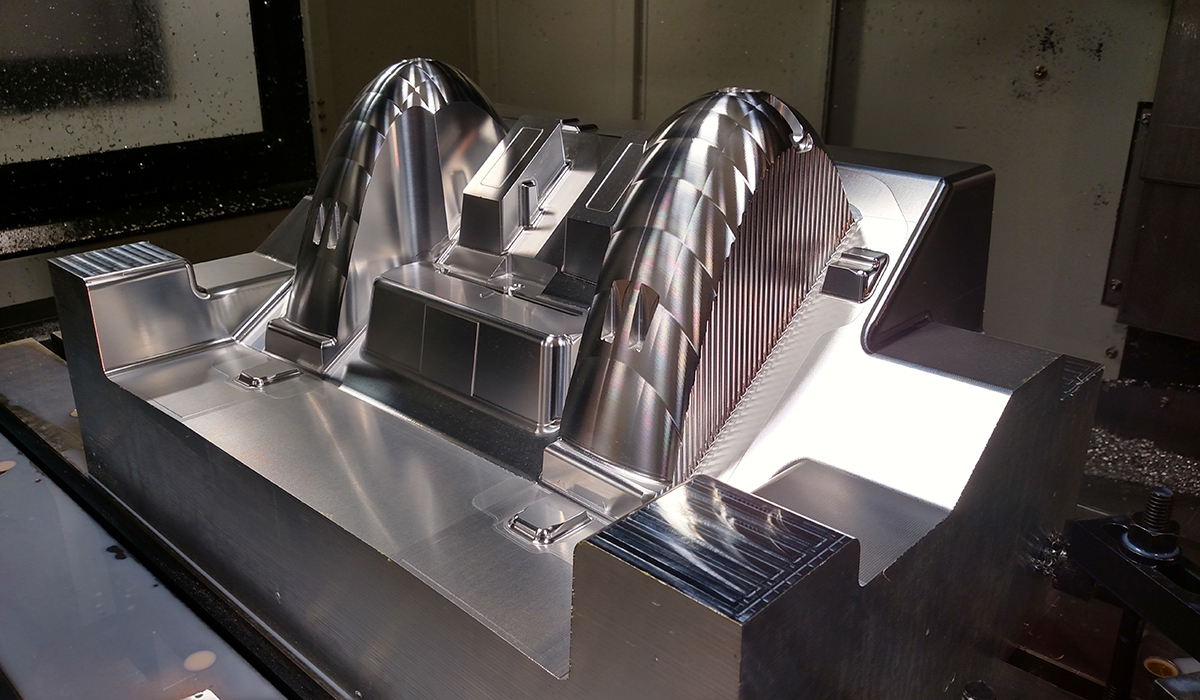

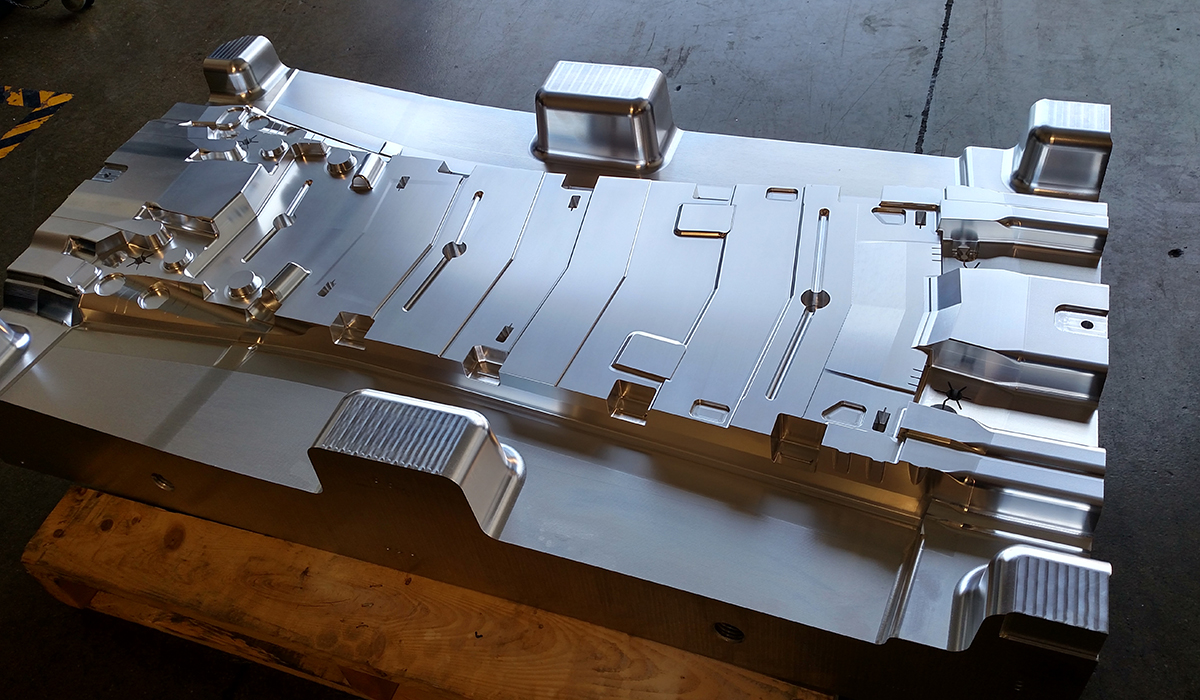

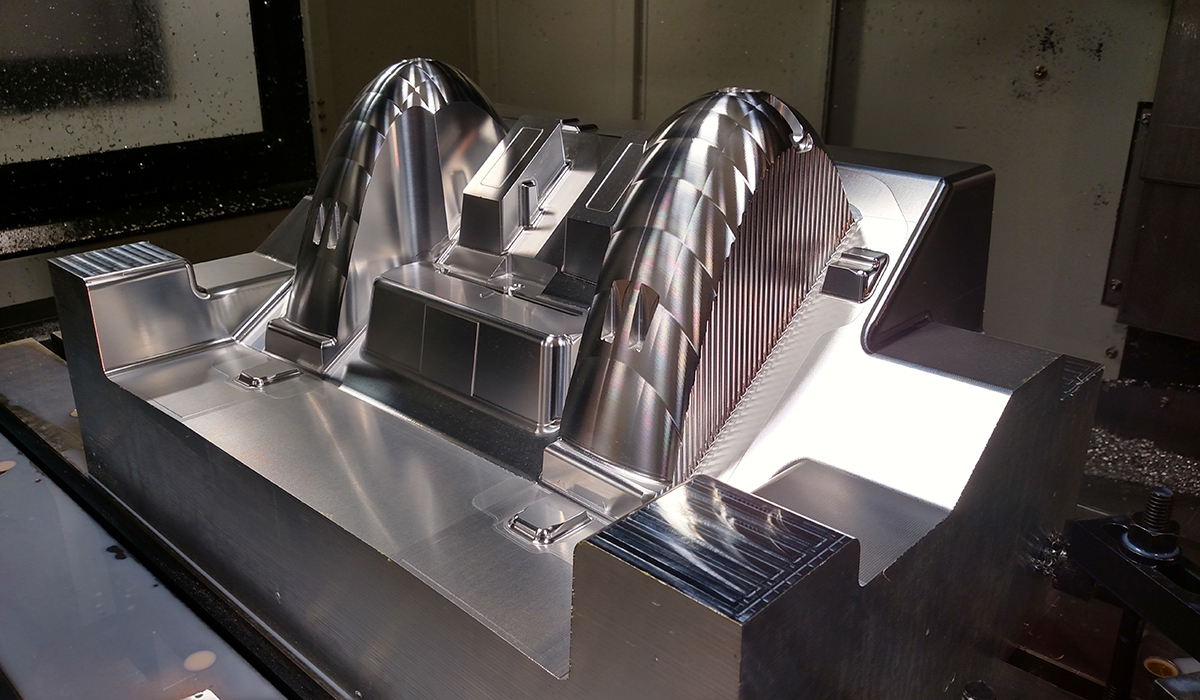

The machining of automotive injection tooling accounts for the lion’s share of business, followed by various aerospace parts — particularly fixturing and forms — and medical products, such as implants. “We have a wide array of customers,” says Andreas, who adds that he also has a lot of competition. “Sable prides itself on going the extra mile to provide very high-quality work, and exceptional surface finishes.”

汽车注塑模具加工占据了Sable的大部分业务,然后依次是各种航空航天零部件—尤其是夹具和模型—以及医疗产品, 例如机械植入物。 “我们的客户群体非常广泛,” Andreas说。接着他又补充道,他们也面对着很多竞争。“但Sable一直致力于为用户提供高品质产品及保证产品的优质表面光洁度。我们以此为豪。”

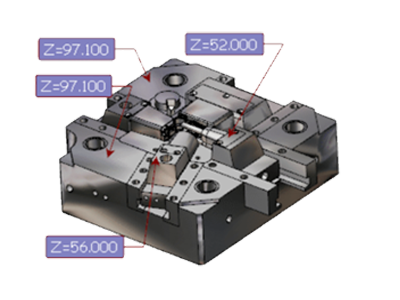

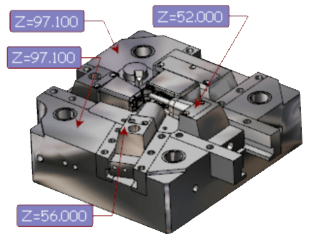

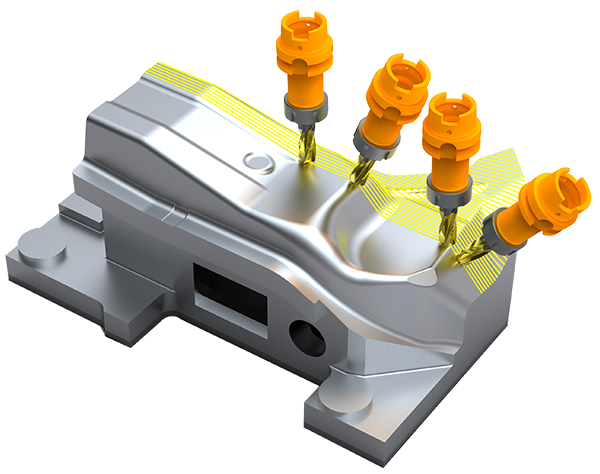

Sable’s equipment includes 8 CNC Machining Centers — both three and 5-axis — with multiple fixture setups on each. This combination of steep financial investment and machine-tool complexity prompted Andreas to invest in a reliable computer-aided-manufacturing (CAM) solution that would enable him to maximize and protect his machinery.

Sable拥有8台CNC加工中心—其中4台为三轴和4台为五轴,并给每台机器都配置了多种夹具装置。对于复杂性机床的大幅度资金投入,促使Andreas要投资一款可靠的、能够最大限度保护机床安全的CAM编程软件。

As a long-time manufacturer, Andreas is well versed in the offerings of the CAM market. He was familiar with the WorkNC CAM solution, by Vero Software, upon opening his business, and has since found that it has fulfilled Sable’s needs. “We use WorkNC because it allows us to have multiple fixture setups on all of our CNC machines,” he says. “Some of the parts we produce can be plus or minus .0002.”The majority of materials machined at Sable are aluminum, P20 steel, H13 hard steel, stainless steel, and plastics, which can be challenging to cut due to an abrasive carbon contents.“In other words,” Joe says, “this isn’t your grandfather’s machine shop.”

作为一名资深的制造商, Andreas深谙CAM市场的产品。自创业之日起,他就非常熟悉Vero公司的WorkNC,同时发现WorkNC完全能够满足Sable的加工需要。“WorkNC能够使我们在所有CNC加工中心上设置多个夹具,这也是我们选择WorkNC的原因。”他说,“我们生产的部分零部件的加工精度可以是正负.0002”。Sable使用的大部分加工材料为铝,P20钢,H13硬质钢,不锈钢和塑料。由于这些材料中的碳成分耐磨性较高,故切削难度非常大。“换句话说,”Joe 说,“这已不是祖父当年经营的传统的加工店。

Programming with Flexibility 灵活编程

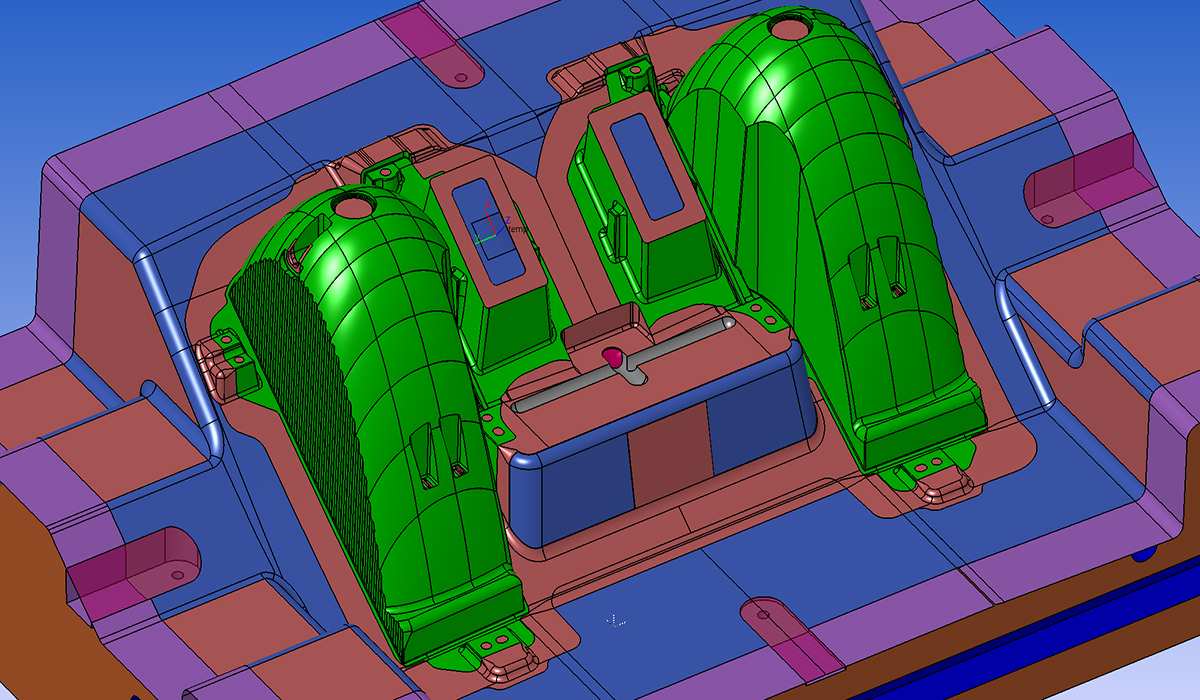

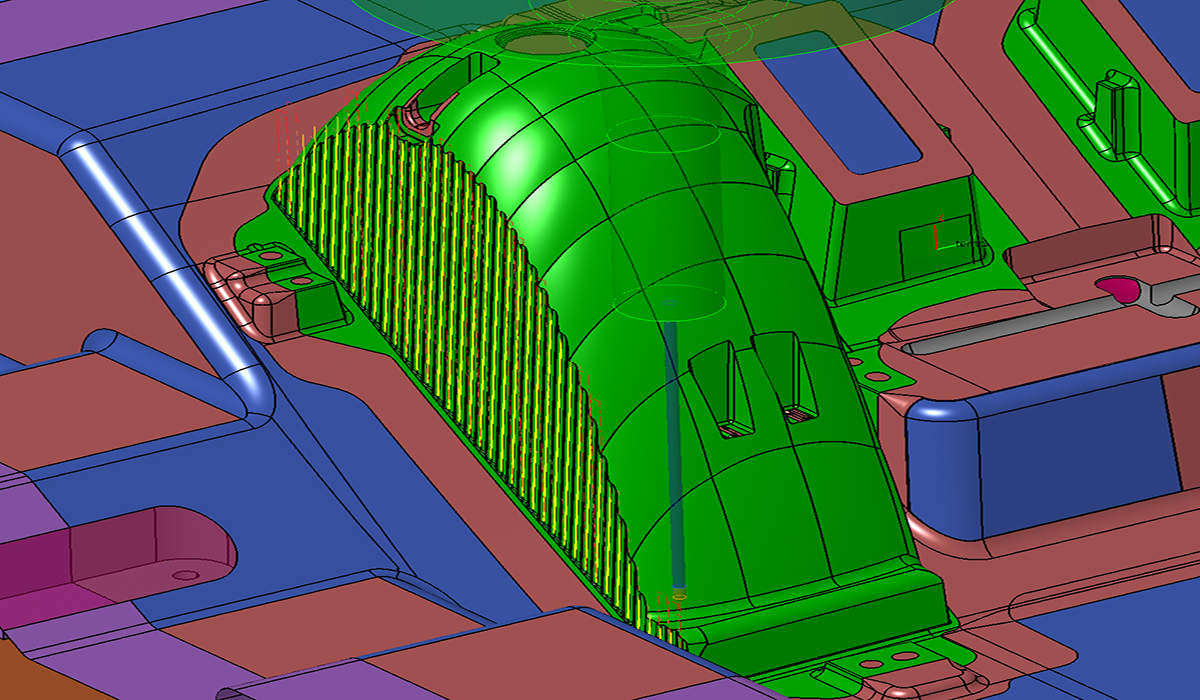

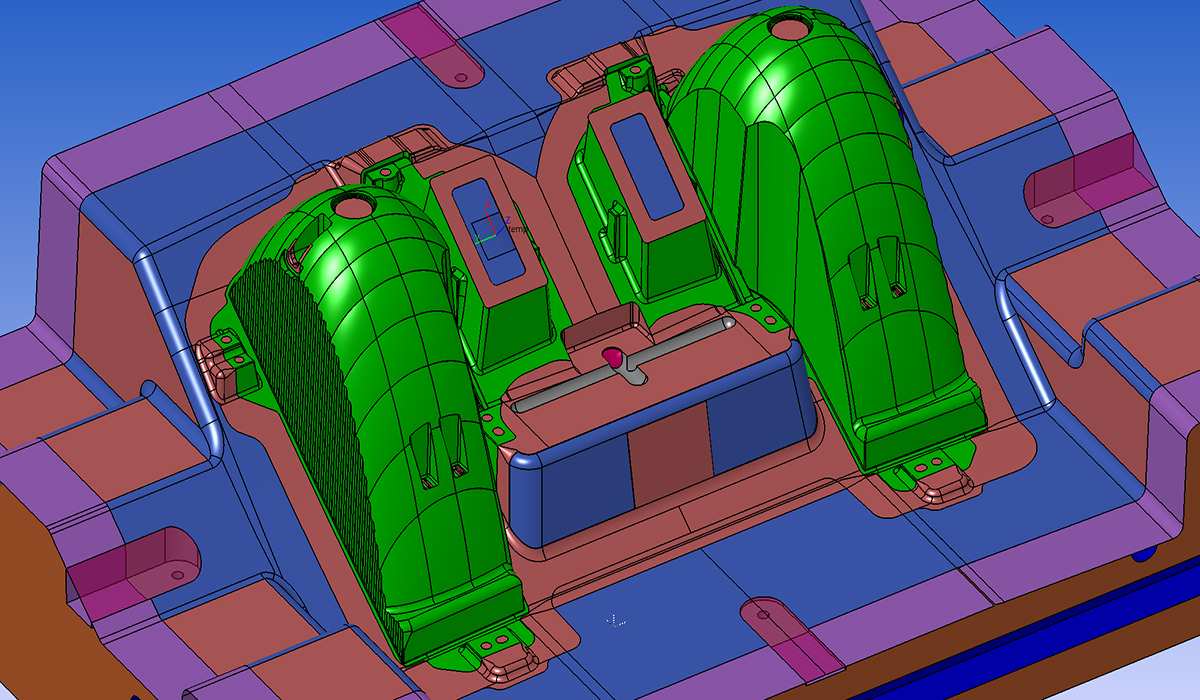

To begin the programming process, programmers at Sable typically import a solid model designed in the Cimatron computer-aided-design (CAD) system into WorkNC. Sable utilizes Cimatron for its major design needs, but also takes advantage of the CAD capabilities within WorkNC to make minor changes during the programming process.

编程开始前,Sable的编程人员通常会把Cimatron中的CAD图形导入WorkNC。Sable利用Cimatron做设计。但是在编程过程中,也会利用WorkNC CAD的优势对原始设计进行小幅度修改。

Due to the associative nature of the CAD and CAM functionality of WorkNC, Sable programmers can make changes to the CAD model that are automatically reflected within the CAM program.“The CAD side of WorkNC will establish how to set up a job, and it’s linked to the CAM side,” Joe says. “In WorkNC, I can switch from the CAM side back to the CAD side to make a change, and it automatically updates the CAM program.”

得益于WorkNC CAD与CAM的无缝连接,Sable的编程人员对CAD模型的修改会自动反映到CAM程序中。“在WorkNC CAD中开始的新工作会自动连接到CAM中,” Joes 说,“使用WorkNC, 我可以从CAM返回到CAD中去做修改,所做的修改会自动更新到CAM程序中。”

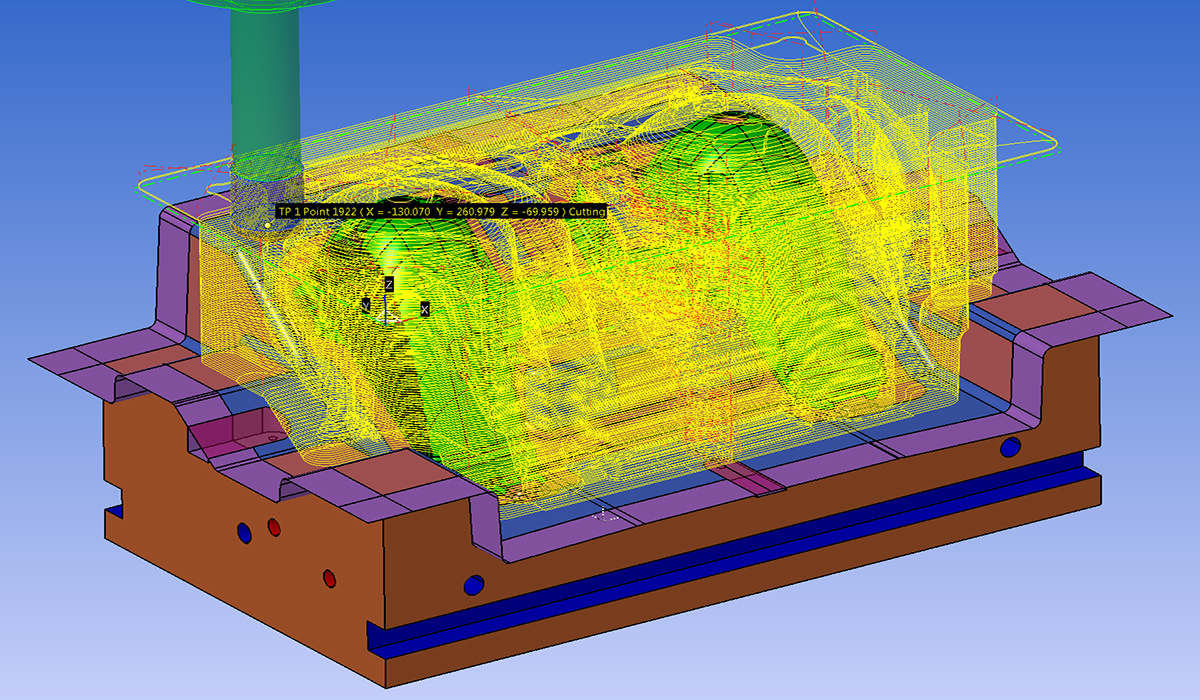

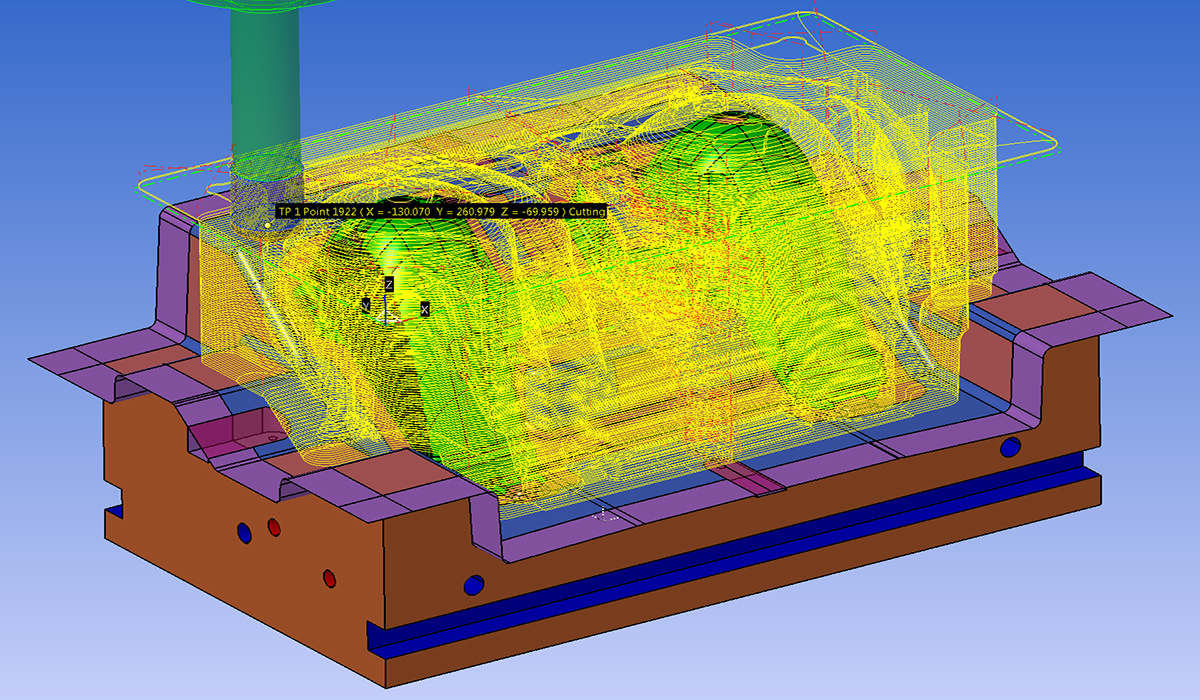

Sable also saves time by utilizing the batch mode capability of WorkNC to program parts and simultaneously calculate multiple toolpaths on separate stock models.“WorkNC will actually process three toolpaths at one time,” Andreas says, noting that it isn’ t uncommon for the company to be working on 15 programs simultaneously.

Sable通过利用WorkNC 批处理计算功能进行零部件编程,同时计算不同库存模型上的多条刀路,有效节省了时间。“在实际应用中,WorkNC能够同时编辑三条刀路,”Andreas 说,一家公司同时自动计算15条刀路很常见。

“There is a lot of software that doesn’t utilize multiple computer processors at the same time,” Joe says of the power inherent to WorkNC. “Back in the old days, you would hit a button to process programs and then go get a cup of coffee.” At Sable, those days are over.The batch mode calculation ability of WorkNC, which keeps the user interface free to tackle other jobs, utilizes the full processing capabilities of the PC.The software’ s parallel 64bit processing functionality also enables multiple cutter paths in the WorkNC workzone to be run simultaneously, provided that any given toolpath is not dependent upon another.

“很多软件不能同时进行多核计算,但是WorkNC可以”,Joe说这是WorkNC自带的强大功能。“回想以前编程的日子,你会点击计算刀路的按钮,然后在计算结束之前去喝杯咖啡。”在Sable,这种日子已经结束了。WorkNC批处理计算功能使用户在编程结束后把计算步骤放在后台批量运行的同时,用户界面仍可处理其他工作,且充分利用PC处理能力。WorkNC 64核并行运算功能让工作目录中的多条刀路能够同时计算,只要他们之间不存在继承关系。

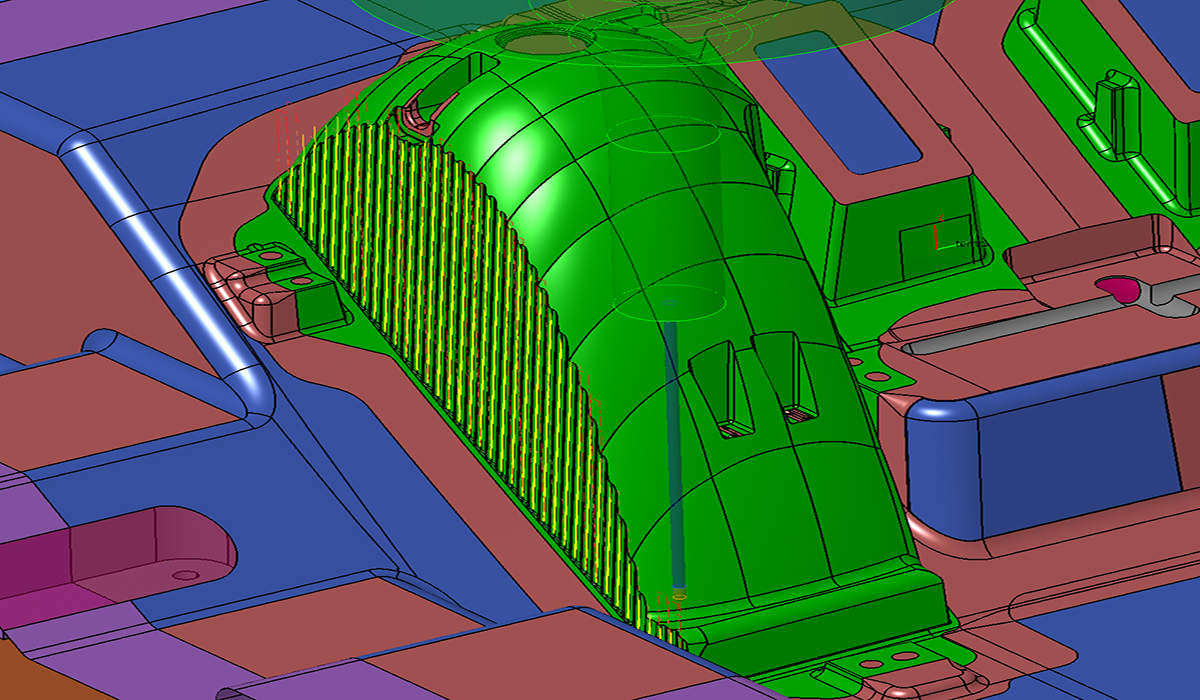

WorkNC’s automatic feature recognition function, which saves the programmer time that would otherwise be invested in identifying and defining the dimensions of part features, is an additional time saver for Sable’s programming department.

WorkNC自动化识别特征功能,节省了编程人员用于识别和定义工件类型、特点以及尺寸的时间,大大节省了Sable编程部门额外需要花费的时间。

Once the CAD model is imported into WorkNC, the software can automatically identify part features to be machined. The flexibility of the system allows for the customization of the process, as programmers are also able to de-select automatically defined features if they’ d prefer, for instance, to wait to machine them.

一旦把CAD模型导入到WorkNC中,WorkNC就能自动识别零部件特征,进行加工。系统的灵活性能够考虑到定制的流程,如果编程人员不想使用此功能,也能够取消自动定义的功能,例如,去等待加工。

“Automatic feature recognition will actually identify all of the holes — whether it’s a tapped hole, a drilled hole, hole, et cetera,” Joe says. “That saves a lot of time.”

“自动特征识别功能可以识别所有孔的类型,无论是螺纹孔、钻孔、还是其他孔,” Joe说。“这为我们节省了很多时间。”

The application of WorkNC workzones to stock models is another time-saving function for Sable. Workzones simplify and maintain the integrity of the programming process while allowing multiple programmers to work on the same program from different locations.

对于Sable而言,WorkNC的工作目录应用于模板编程是另外一个有效节省时间的功能。WorkNC工作目录操作简单,能够保持整个编程过程的完整性,同时允许多个编程人员在不同地点共同处理一个程序。

“You might rough a job and the guy finishing it may be in another building.” Joe explains. “In most cases shops have programmers who can only create rougher programs, and experienced programmers creating finishing paths.”In those cases, a programmer is able to complete the roughing portion of a program, export the stock model with the new parameters, and pass that model off to another programmer.

“你可能负责编辑粗加工刀,而编辑精加工刀路的那个人可能在另外一栋大楼里。”Joe解释道。“在大多数情况下,粗加工刀路由车间的编程人员完成,而精加工刀路由经验丰富的编程人员完成。”在这些情况下,编程人员完成粗加工刀路编辑后,用新的参数导出模板,再把它传给其他的编程人员。

“The software knows what’s left, and where the tool went — and it’s just simpler to give someone a model that’s been worked on,” Andreas says.

“Instead of me scrolling through 14 layers of toolpath, it’s just easier to start with a new model,” Joe adds.

“软件知道余下的工作,以及刀具切削路径。WorkNC模板编程非常简单,只需要给负责的人一个在运行的模板即可。”Andreas 说。

“与其让我浏览14条刀路,还不如从新模板开始操作更加容易,”Joe 补充道。

Embracing New Technologies 拥抱新技术

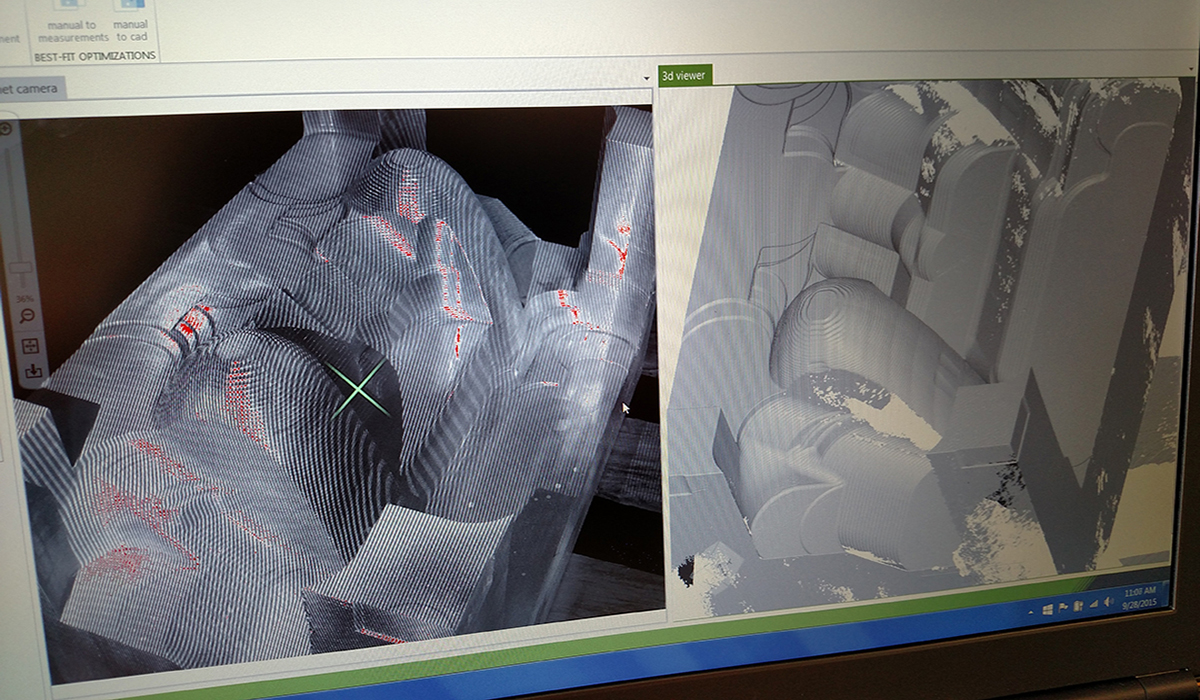

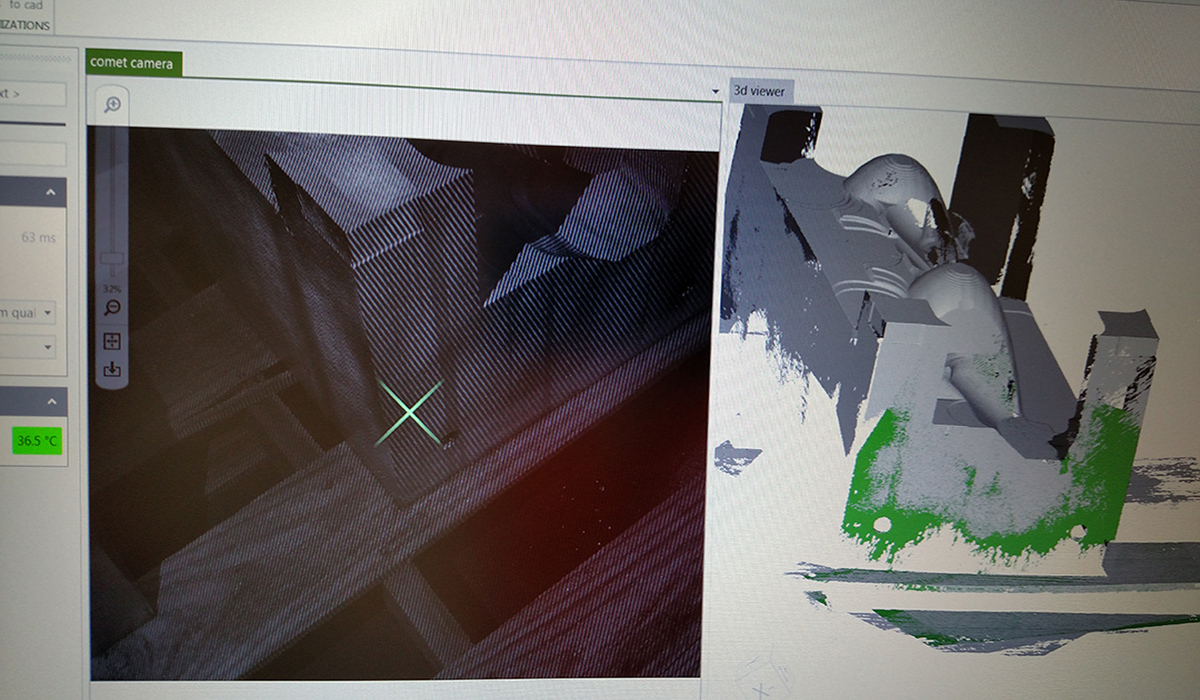

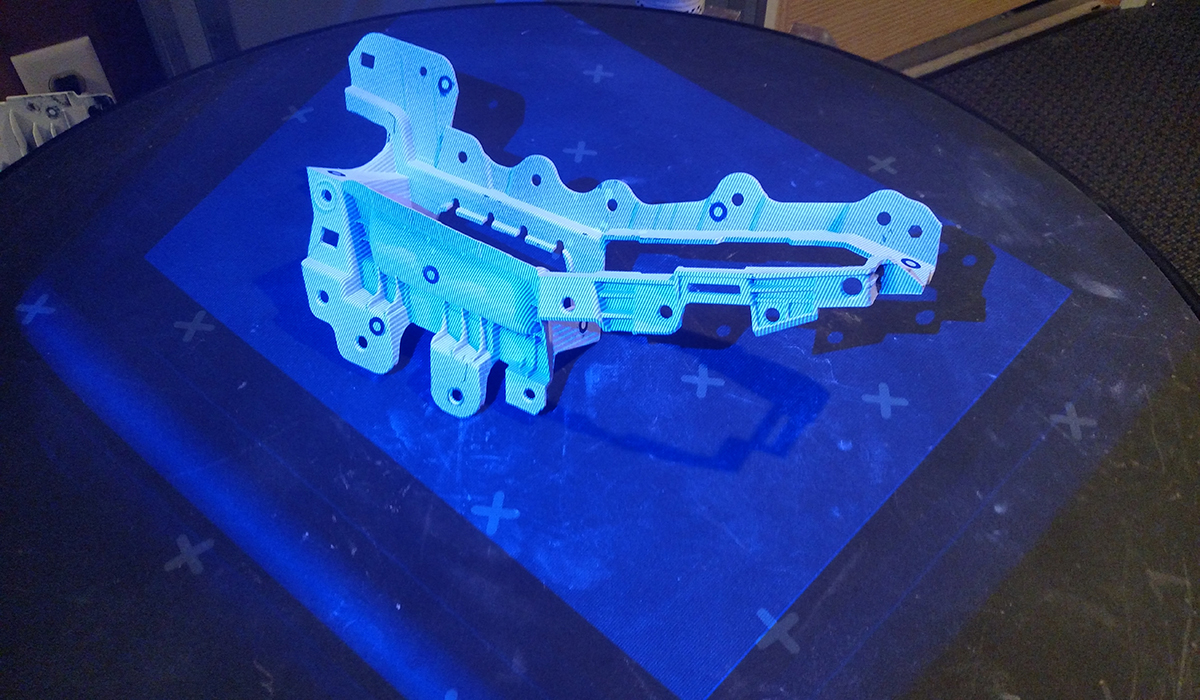

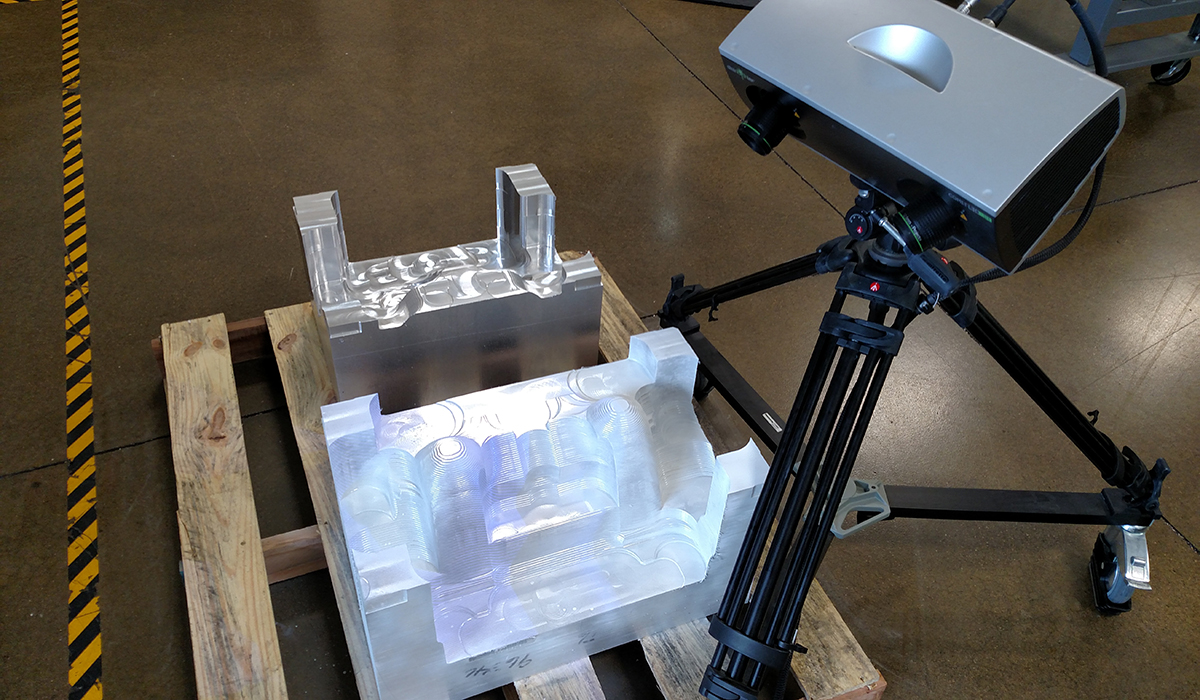

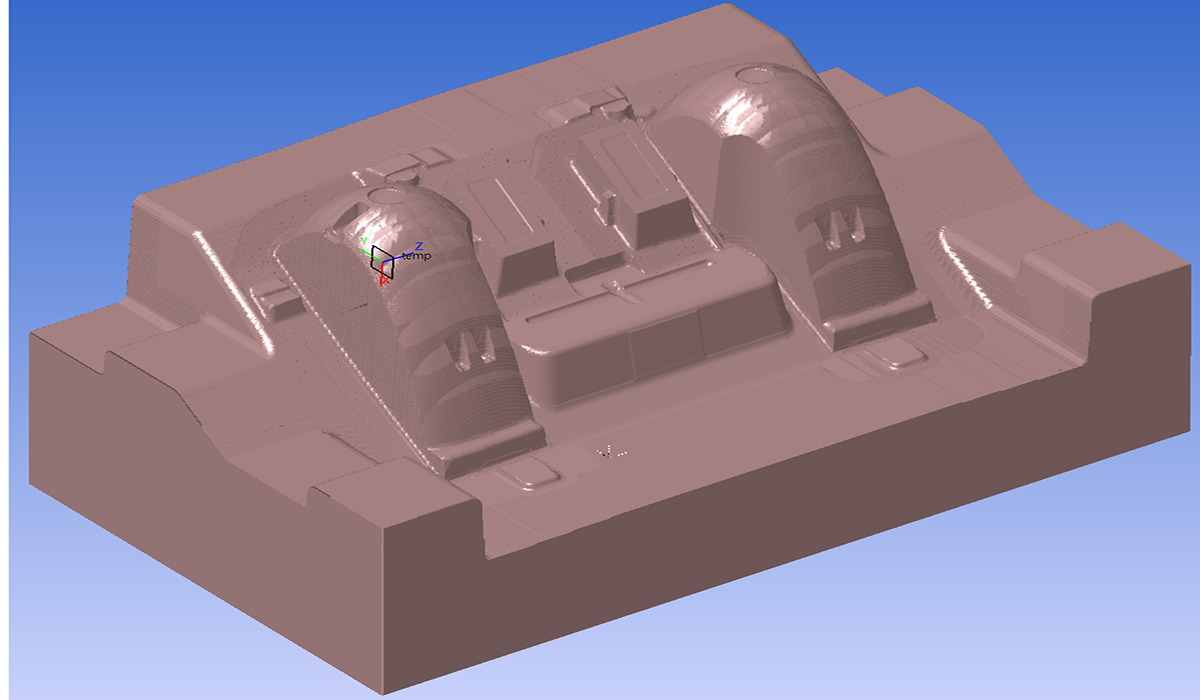

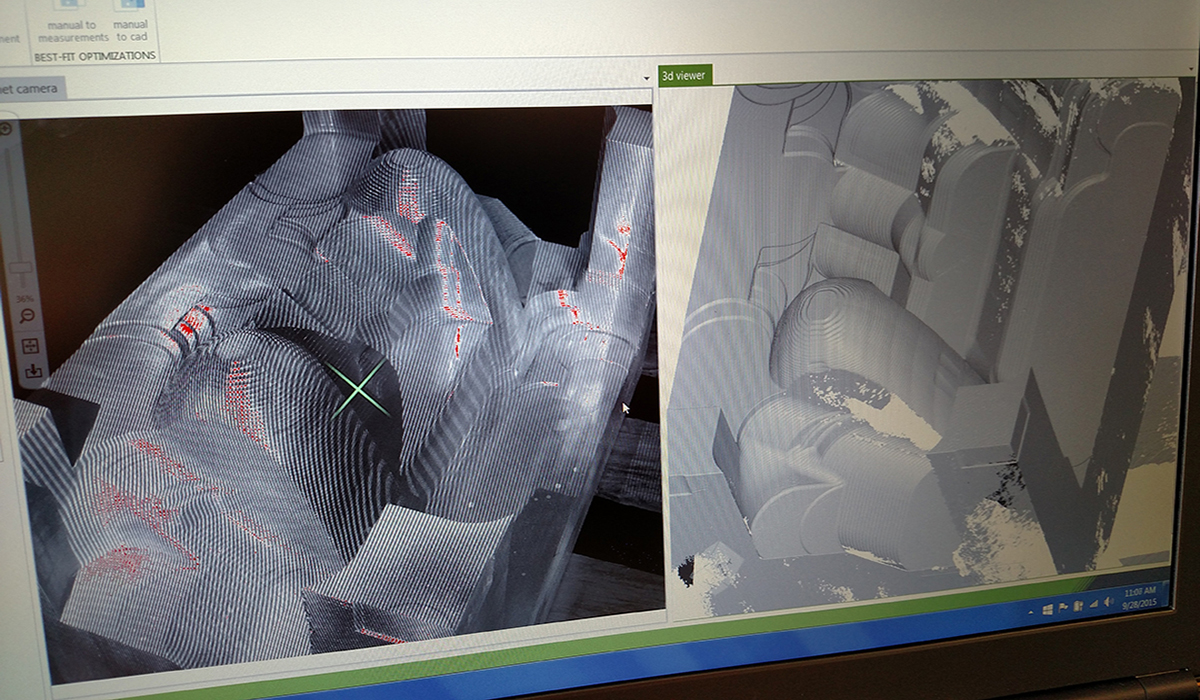

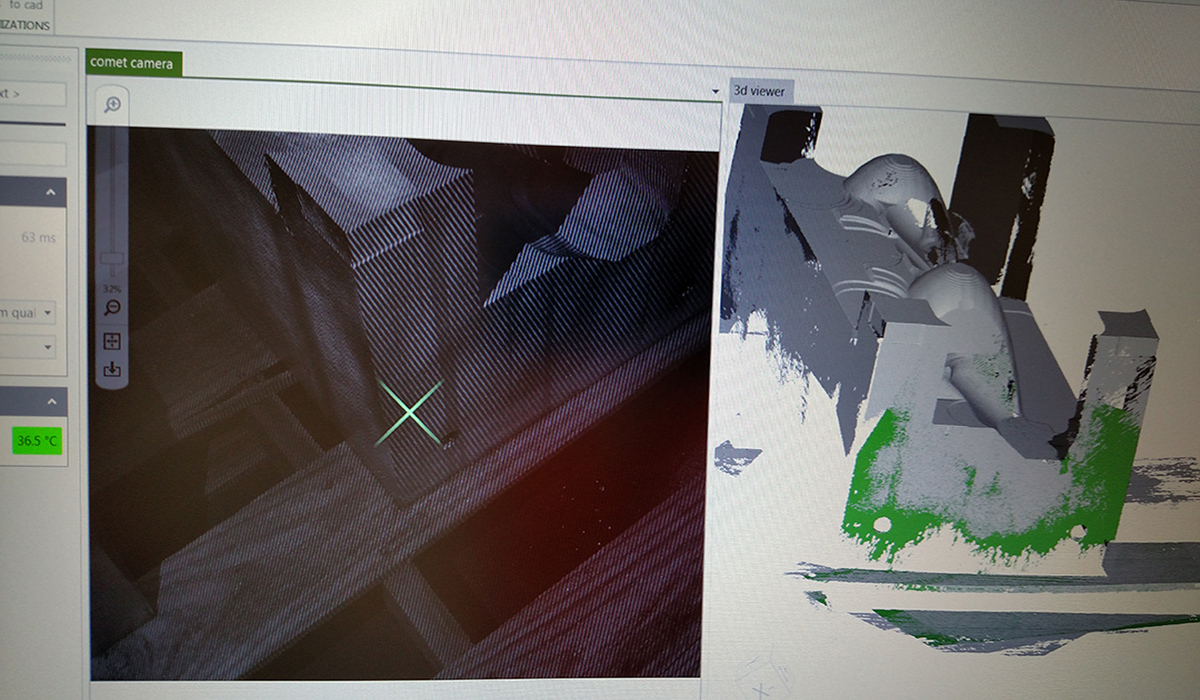

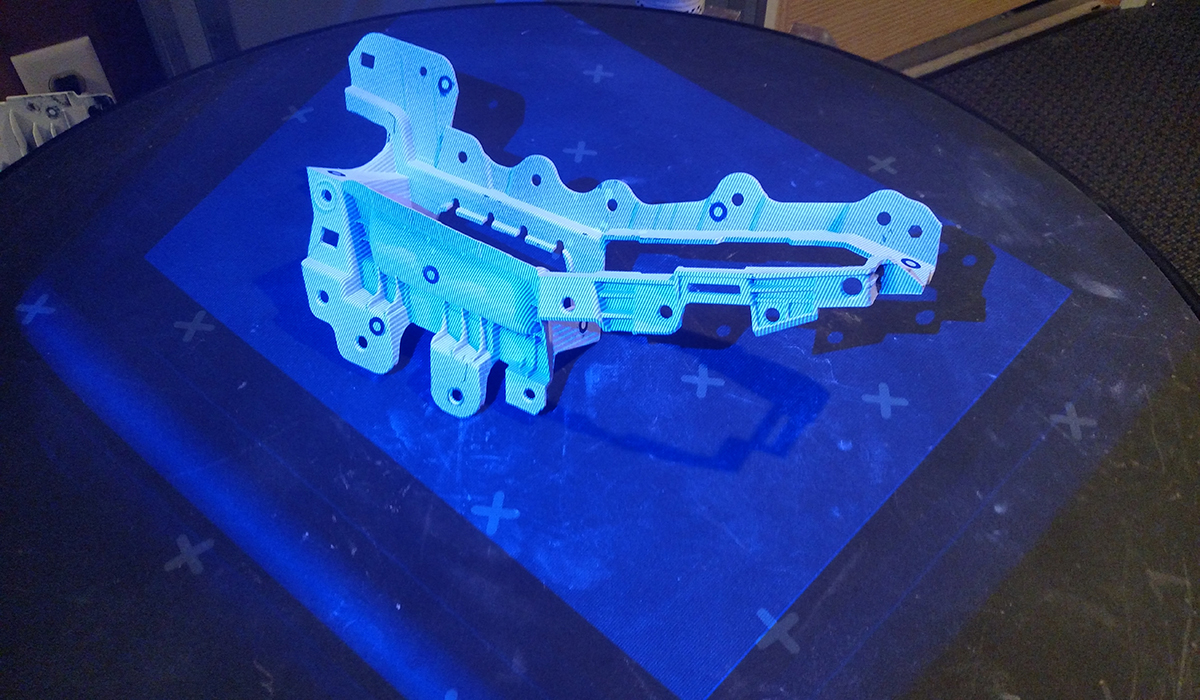

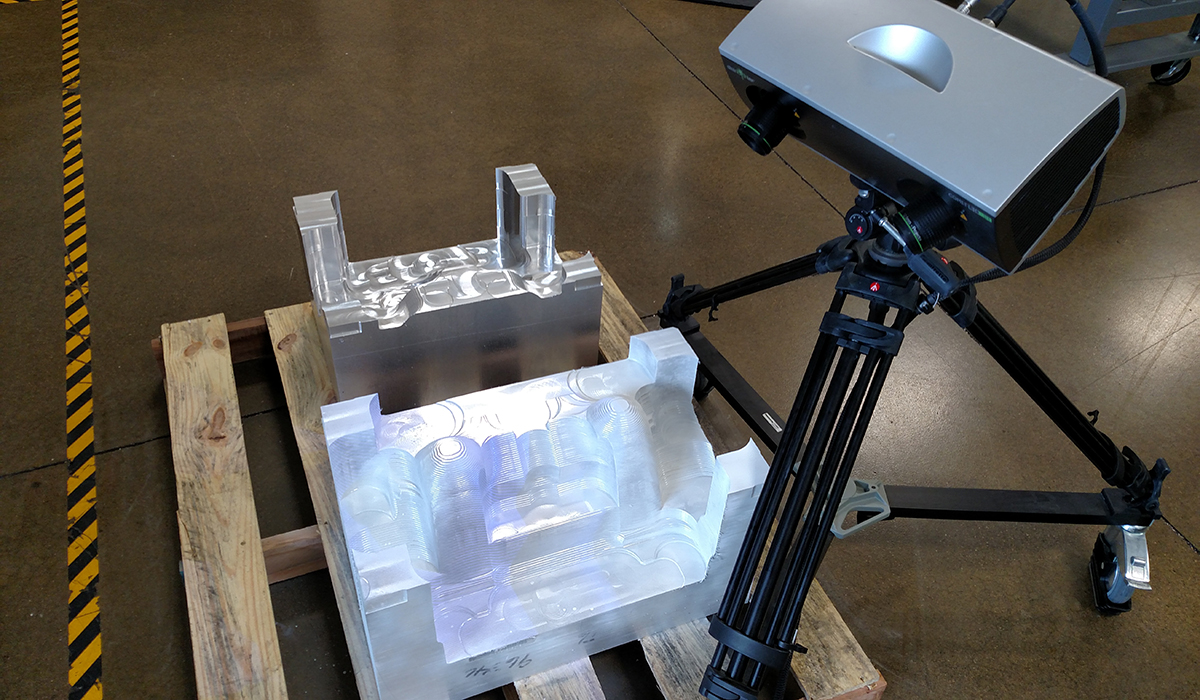

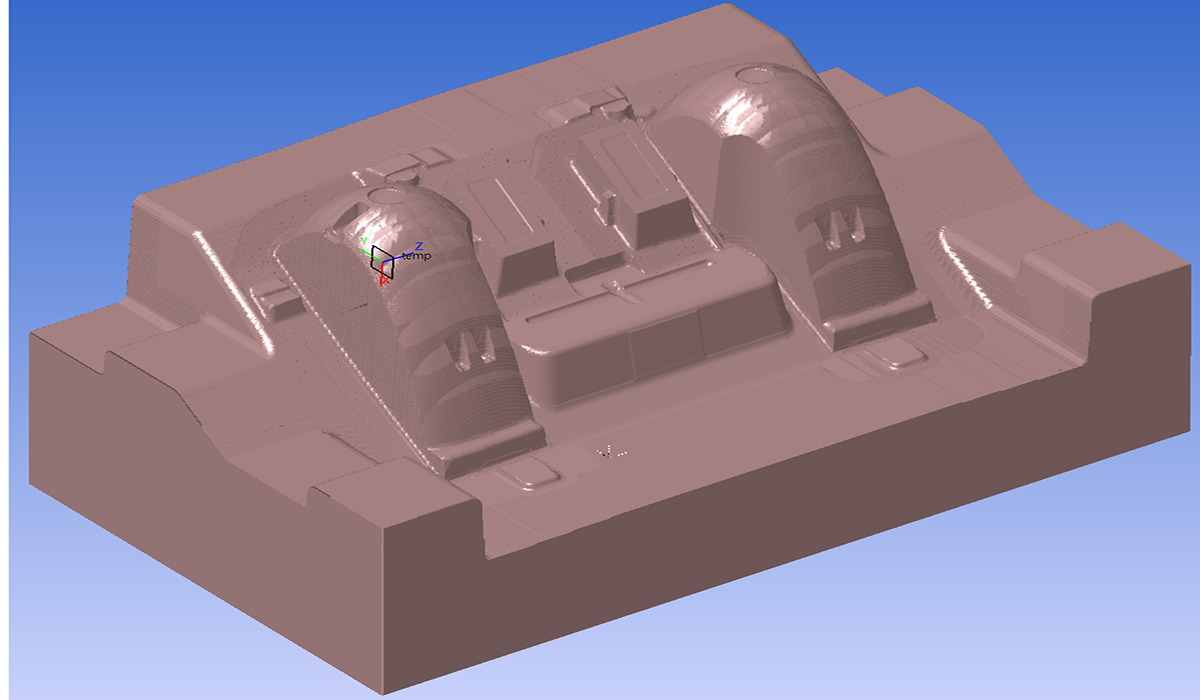

In no instance is Andreas and Joe’s willingness to embrace new and emerging technologies more apparent than it their use of scanning and engineering technology.Sable uses a free-standing Steinbichler Comet L3D 5MP Blue-LED scanner to scan existing parts for reproduction, and to scan parts with dimensions or pallet placements that are challenging to pinpoint. Once the part is scanned, the scanner creates an .STL file that can then be imported into WorkNC.

扫描技术和工程技术的运用, 说明了Andreas 和Joe在任何情况下都很乐意去接受新技术。Sable使用摄像机脚架式Steinbichler Comet L3D 5MP 3D蓝光LED扫描仪扫描现有零件,用于复制加工。扫描难以定位的不同尺寸零部件或底盘。一旦扫描成功后,扫描机会创建一个.STL格式文件,然后将其导入到WorkNC中。

“It’s not so much saving time as knowing where you are,” says Joe of the use of a scanner for identifying part dimensions and exact location. He adds that, with jobs involving raw castings or the use of palletized machines, the use of the scanner enables the programmer to get an accurate fix on a workpiece.

“扫描仪识别零件尺寸和其所在的确切位置,为我们节省了很多时间”Joe 说。他又补充道,在涉及生铸件或使用托盘式机器的工作中,扫描器的使用能够让编程人员准确锁定工件位置。

“Without scanning rough-cut work pieces or casted parts, it would require our programmers to spend numerous hours to re-qualify existing machined areas,” Joe says.

“未经扫描的粗切工件或压铸零部件,就需要我们的程序员花费大量时间重新鉴定现有加工区域,”Joe说。

“You can’t run your machines unattended if you don’t know where your parts are.” Andreas adds. “The technology for scanners has grown exponentially in the last three to four years.”

“如果你不知道零件的准确加工区域,就不能让机床在无人看管的情况下运行。”Andreas补充道。 “扫描仪技术在过去三到四年内呈指数增长的状态快速发展。”

Most notably, scanners are able to manage data much more quickly than ever before. The ability of CAM systems like WorkNC to utilize the data further drives the development of scanning for manufacturing purposes.

最值得注意的是,与以前的技术相比,扫描仪能够更快的速度进行数据管理。而像WorkNC这样的CAM软件有效利用数据的能力进一步推动了生产管理中扫描技术的发展。

Sable’s Steinbichler scanner, paired with its CNC machinery and WorkNC, makes it possible to complete work that would have taken a week or more in just a few days.

Sable把 Steinbichler扫描仪搭配CNC加工中心和WorkNC使用,使需要花费一周或更长时间的工作可能在短短几天就能完成。

“For example,” Joe says, “one of our customers supplied Sable with tuned V-6 throttle bodies, hand ported and polished. By laser scanning the first hand-worked throttle body, our engineers created a solid model for CNC machining. It took the guy a week to make the first part — but it only took me 90 minutes to complete the same part with our CNC equipment.”

“例如,”Joe说,“我们的一位客户向Sable提供了经过调整的、抛光的、装有手动气门的V-6节流阀体。通过激光扫描手动操作的第一个节流阀门后,我们的工程师为CNC加工中心创建一个实体模型。工程师花了一个星期只能完成加工中心模型的第一部分,但是我利用WorkNC只用了90分钟就轻松完成了。”

Though Sable has clearly met with success in part because of his pioneering spirit, Andreas is quick to point out that realizing his company vision was, in some aspects, a group effort.“We are very dedicated to our customers,” he says, “and appreciate everyone involved with helping Sable Engineering grow into the company we are today.”

尽管是Sable的开拓精神,使他在零部件加工行业获得了成功。但Andreas又很快指出,从某些方面讲,一个团队的共同努力帮助他实现了公司繁荣发展的愿景。“我们致力于满足客户需求,”他接着说,“同样感谢每一位参与帮助Sable发展的人。正是在他们的帮助下,Sable才能发展得像今天这么好。

WorkNC

WorkNC