用户简介公司名字:

Julien SA

业务:

模具制造商

地址:

法国

公司网址:

www.juliensa.com

给Julien SAa带来的价值:

高效交货时间、产品质量和专业性让JulienSA在竞争对手中脱颖而出

WorkNC强大的CAD和CAM功能解决了在技术上遇到的所有问题

WorkNC的CATIA接口使JulienSA能够重新建立关键的CATIA构造树

WorkNC强大的编程能力实现无人值守加工,工厂能够24小时运转

加工设备:

5轴加工设备:Breton(柏瑞通)、 Durango(杜兰戈)和Rambaudi(蓝苞蒂)

3+2轴加工设备:Goglio(高利尔)、FPT、Anayak(阿纳亚克) 和Soraluces(索拉露斯)

客户反馈:

“It

means the workshop operates 24/7. From middayon Friday and over the

weekend, it is fully autonomous, with automatic toolchanging and head

rotation. We couldn’t do that without WORKNC.”

“WorkNC使我们车间24小时运转,从周五正午到整个周末,完全自动化生产,自动换刀具和机床运行。没有WorkNC,我们就无法做到。”

—Sergio Couto, Programming Manager

A

mold maker serving the automotive industry says WORKNC software

givesthem a distinct advantage, setting them apart from their

competitors withsuperior lead-times, quality and expertize. And as a

Beta tester for WORKNC,they found that a new item of functionality,

subsequently introduced into thelatest release – 2019 R1 – slashed their

finishing machining times by more thanhalf on certain parts.

汽车行业的模具制造商JulienSA说,WorkNC带给他们独一无二的优势,使他们在交货时间、产品质量和专业性方面在竞争对手中脱颖而出。JulienSA是WorkNC Beta测试员。他们发现的一个新功能被引入至最新发布的2019R1软件版本中。这一功能加工使某些工件的精加工时间减少一半以上。

Operating

from three sites in France and one each in Turkeyand Slovakia, Julien

SA manufactures molds for interiorlinings, boot compartment trim, and

roof linings, along with parts forsoundproofing, foamed parts, and

aluminum and textile thermal barriers.

JulienSA在法国有三个工厂,在土耳其和斯洛伐克各有一个工厂,主要生产内饰件,行李箱内饰和车顶内饰模具,以及隔音部件,发泡零件,铝和纺织品热障的部件。

They

mainly produce single orderparts, or two to three small series molds

for foam parts. Based at the10,000 square-metre head office in Le

Creusot, France, Programming ManagerSergio Couto is responsible for

preparing production and implementing theproduct manufacturing process.

His department takes the lead on a range of aspects such as technical

issues, monitoring and qualitycontrol for toolingproduction.

JulienSA主要生产单件订单 或者2-3个发泡零件的小系列模具。Julien SA的总部位于法国Le Creusot, 占地面积10000平方米,编程经理Sergio Couto负责生产准备和生产过程执行。他的部门负责例如技术问题解决,监督和控制模具生产质量等方面的事宜。

Although

they make a small number of molds for theaerospace industry, most of

their customers are major automotive groups who need tight turnaround

times. Using WORKNC’s powerful CADand CAM capabilities, he says

practically nothing is impossible from atechnical point of view.

Julien SA生产航空航天行业的模具数量不多,他们很多客户主要是要求生产周期短的汽车集团。Sergio Couto表示,WorkNC强大的CAD和CAM功能让他们在解决技术问题上无后顾之忧。

The

software is installed on seven computers on thecompany’s network, and

drives three 5-axis machine tools: a Breton, Durango andRambaudi; and

four 3+2 machines: a Goglio, FPT, Anayak and Soraluces.

WorkNC配置在7台连公司网络的的电脑上,应用于3台五轴加工设备::Breton(柏瑞通)、 Durango(杜兰戈) 和Rambaudi(蓝苞蒂),以及4台3+2轴加工设备:Goglio(高利尔)、FPT、Anayak( 阿纳亚克)和Soraluces(索拉露斯)。

Explaining

how WORKNC is an integral and vital part oftheir full production

operation, he says the process begins after theirprogramming team

receives an assessment from the engineering office with thepurchase

order. “Firstly, we analyse the CATIA file of the part to be

produced,allowing us to isolate items which need to be precize, and to

determine what’sfeasible.

Sergio Couto解释了WorkNC在他们整个生产过程中不可或缺的原因。他说,整个编程工作起始于他们编程团队收到工程办公司采购单的评估。“首先,我们分析待加工件的CATIA格式的文件,使我们挑选出需要精确的项目,决定可行的项目。”

“With

the aid of WORKNC’s CATIA interface we canre-establish the CATIA

construction tree, whichis crucial, as that data is of paramount

importance to our business. WORKNC isone of the rare applications which

allows this.”

“借助WorkNC的CATIA接口,我们能重新建立关键的CATIA构造树。因为这些数据对于我们的业务非常重要。WorkNC是为数不多支持这个功能的软件。”

They

then turn their attention to the number of parts theyneed to produce,

and create the models in WORKNC, addingoffset allowances, and any other

details required for accuratemachining.

他们随后准备需要生产的零件数量,在WorkNC中创建模型,增加偏置余量,以及其他实现精确加工的细节。

“The

next step is to prepare the production phase and runtoolpath

calculations. We establish machining schedules and adapt WORKNC

toolpathsto the specific machine being used.”

“下一步就是生产准备阶段和刀路计算,我们制定加工计划,并根据使用的具体机床调整WORKNC刀路。”

However,

Sergio Couto says that occasionally they don’tknow which machines will

be available, meaning they need to generate generictoolpaths. “This

highlights the importance of Machining Contexts in WORKNC,because we

often have to switch to another machine at the last moment.”

然而,Sergio Couto说道,有时他们不知道哪台机床是可用的,所以着他们需要编辑通用刀路。“这强调了WorkNC的工作目录的重要性,因为我们常常不得不在最后一刻转到其他设备。”

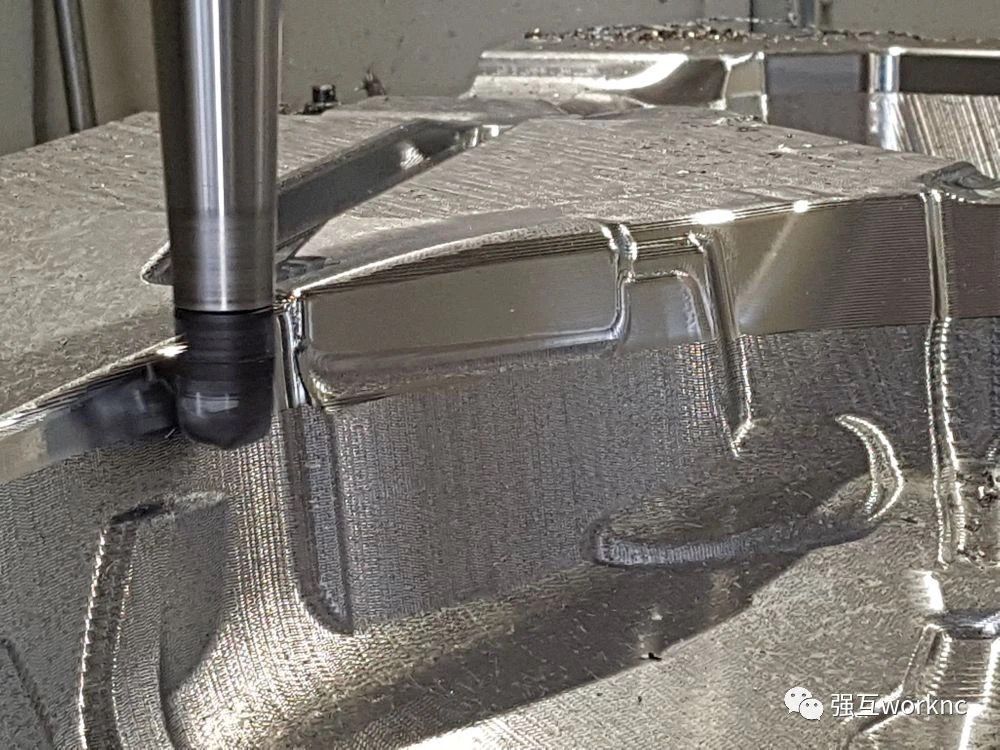

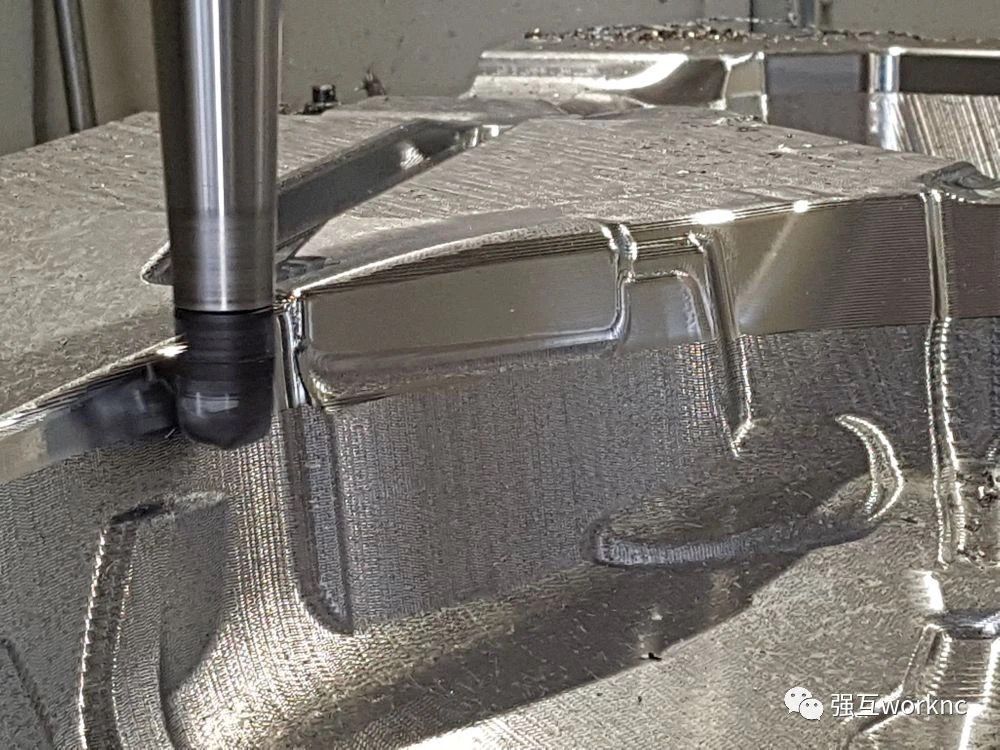

The

final phase is in the workshop, where WORKNC’ssimulation function

validates the process beforethe machines start cutting metal. And he

says WORKNC’s powerful programmingallows them to undertake lights-out

machining. “It means the workshop operates24/7. From midday on Friday

and over the weekend, it is fully autonomous, withautomatic tool

changing and head rotation. We couldn’t do that without WORKNC.”

最后上机前,在车间利用WorkNC仿真模拟功能验证刀路可行性。SergioCouto说,WorkNC强大的编程功能 使他们能够无人值守加工。“没有WorkNC,我们就无法实现车间24小时运转。从周五正午到整个周末,WorkNC完全自动化生产,自动换刀具和机床运行。。”

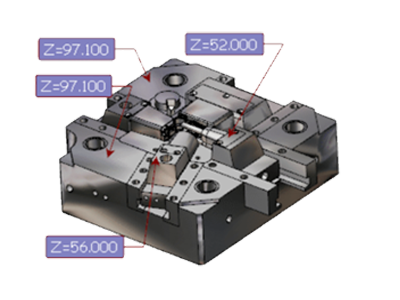

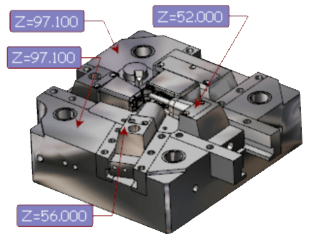

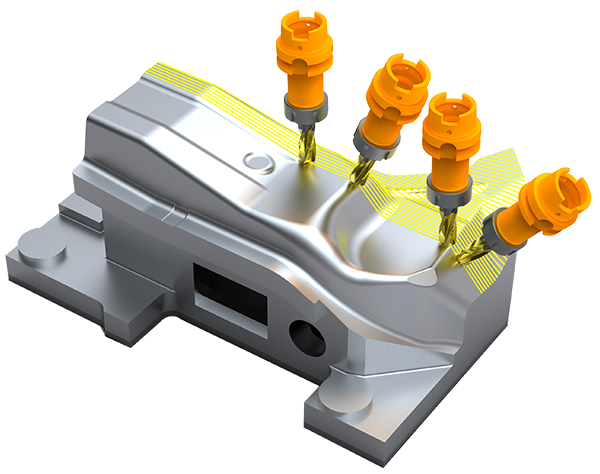

As

a Beta tester for WORKNC, Julien SA trialed a newfinishing strategy

which allows users to break free from previous constraintscaused by tool

shapes, and it has slashed their machining times by more thanhalf. As a

result of the trials, WORKNC 2019 R1 adds the Z-Level pattern to the

Advanced Toolform technology,allowing for tool shapes like barrels,

ovals and parabolic to be calculatedover the part surfaces, including

negative allowances.

作为WORKNC的Beta测试者,Julien SA测试了一种新的精加工策略,该策略让用户摆脱刀具形状的限制,使加工时间减少了一半以上。作为试验的成果,WORKNC 2019 R1在高级成型刀加工策略中添加了高等切削,允许在零件表面计算桶形,椭圆形和抛物线形状等刀具形状,包括可以用负余量进行计算。

Sergio

Couto says the results of using theAdvancedToolform strategy with

circular-segmentcutters compared to traditional methods, are

indisputable, having reduced their finishing machining timesfrom 32

hours to 14.

Sergio Couto表示,与传统的方法比较,支持异形刀具的高级成型刀加工策略的效果更加明显,已让他们的精加工时间从32小时减少到14个小时。

WORKNC,

part of the Production Software business of HexagonManufacturing

Intelligence, is fully integrated into every machining phase –analysis,

comparison, simulation, machining and verification. “Today, we also use

it to transmit data to the workshop, through WORKNC Viewer.

WorkNC是海克斯康智能生产软件之一,能够完全集成到每一个加工阶段的分析、比较、仿真、加工和验证。“现在,我们也可以使用它通过WorkNC Viewer将数据传递到车间.”

Summing

up the benefits of using WORKNC, Sergio Couto saystoolpath calculation

times are no longer an issue. “We manufacture some largeparts – 2m x

1.5m – and it’s very rare that calculationtimes are longer than eight

hours for all roughing,finishing, rest material, corner re-machining and

mechanicaloperations such as drilling and pocket machining. And it’s

auser-friendly application that’s so easy to learn…even for our

employees who’venever done any programming before.”

Sergio Couto总结了使用WorkNC编程加工的好处,表示计算时间不再是问题。“我们制造一些尺寸为2m x 1.5m的大型工件时,所涉及开粗、精加工、二粗、清角加工,以及例如钻孔和口袋加工等机械操作的所有计算时间不超过8个小时非常罕见。同时WorkNC是一款用户友好型软件,好学易用,同样适用于我们此前没有任何编程经验的员工。”

The

company has also invested in a mobilemeasuring arm from Hexagon, to

make precize measurements at differentstages of the manufacturing

operation. They use it to make immediate decisionsto either modify or

continue the process when a doubt arises, which he saysguarantees

security, saving time. “This all helps with the precision we need

toactually manufacture the part, ensuring it’s of high quality, and that

it canbe cleanly and accurately trimmed, which is particularly

important for itsfinal appearance, as many of the parts coming out of

our molds are visible tothe end user in the vehicles.”

Julien SA从海克斯康引进了移动测量臂,用于精确测量不同生产阶段。当遇到问题时,JulienSA可以利用它立即决定是选择修改还是继续,保证安全,节约时间。“这可以帮助我们保证实际加工件的精确性和生产品质,精确又清晰地削剪对于最终形状的形成尤其重要。因为我们加工的模具零件都是汽车外饰件。”

Concluding,

he explains why they first invested in WORKNC inthe 1994, and how it

has developed since then: “In the 90s mold makers startedreceiving files

from India and China, in which radii and planar surfaces didn’tconform

to the original part, and it was no longer possible to program

withCATIA. Even back then, WORKNC could rapidly generate a toolpath,

irrespectiveof a part’s complexity, and imperfect surfaces.

Sergio Couto解释了为什么他们在1994年引进WorkNC,以及之后WorkNC如何在他们公司得到重用:“20世纪90年代,模具制造商开始接受来自印度和中国的工件,但是这些文件中有一些不符合原零件的半径和面。仅用某一款软件就无法满足他们编程的需要。即使面对表面粗糙且复杂的加工件,WorkNC仍然能够快速产生刀路。”

“WORKNC

has developed in line with requirement of millingoperators, who had

previously programmed toolpaths directly onto the machinetools. We have

total confidence in working with it on a daily basis, andit helps us to

take issues such as holidays, sickness absences and machinedowntimein our stride. It means we can set ourselves apart as amold makers, ahead of our competitors.”

“WorkNC符合铣床操作员的要求,操作员把编辑好的刀路直接应用到机床上。WorkNC让我们对日常加工非常有信心。他能够帮助我们解决各种问题,例如员工假期,病假,设备故障等。WorkNC让我们在模具制造商中脱颖而出,使我们远远领先竞争对手。”

更多WorkNC资讯,扫码关注微信公众号:qh_worknc

|

WorkNC

WorkNC