用户简介

公司名字:

Dixence

业务:

工业橡胶注塑模具和冷流道模块制造

地址:

法国

公司网址:

www.dixence.eu

给Dixence带来的价值:

WorkNC提高了生产力和精加工品质

WorkPLAN统筹所有信息,例如销售订单、采购订单、时间管理、发货单和发票等,并可完全追踪与每个项目相关的信息

WORKPLAN记录关于材料数量、成本和任务时间的数据,快速计算模具成本预算,从而逐步提高盈利能力

加工设备:

三台Huron(优龙)、两台Mazak(马扎克)立式铣床、两台Mazak(马扎克)卧式铣床、HSM铣床

客户反馈:

“Our programmers often use standard

WORKNC toolpaths such as 3-axisFinishing and Contour Remachining(Contour Remachining), which wefind perfect for producing a

high-quality finish on curved surfaces where thereare no right angles.”

“我们的编程人员常常使用标准的WorkNC刀路,例如三轴精加工和轮廓再加工,我们发现这非常适合用于无直角曲面精加工,可以保证其高品质的表面。”

——Fabrice Provost, Milling Sector Manager

A company

specialising in industrial rubber injectionmoulds and cold runner blocks for

the automotive sector uses WORKNC to create3+2 axis toolpath programs across a

range of eight CNC machine tools andWORKPLANto consolidate a variety of

information from sales orders to invoices.

Dixence is an

SME operating with around 30 staff out of a1,500 m2 workshop and 500 m2

engineering department at Erbray, in WesternFrance.

Dixence是一家专门给汽车行业提供工业橡胶注塑模具和冷流道块的公司。Dixence利用WorkNC为8台机床创建3+2轴刀路,以及使用WORKPLAN整合从销售订单到发票的一系列信息。

Dixence是一家中小型企业,位于法国西部的Erbray,拥有1500平方的厂房和500平方米的工程部,约有30名员工。

Their main

business is designing and manufacturing toolingequipment, and manufacturing

moulds for all-rubber bonded inserts, and plastic,metal and rubber parts.

Managing Director Gérard Beloeil says these can beinjection, compression,

regulated transfer or cold plate moulds produced indifferent grades of steel;

pre-treated, hardened, and with a special coating.

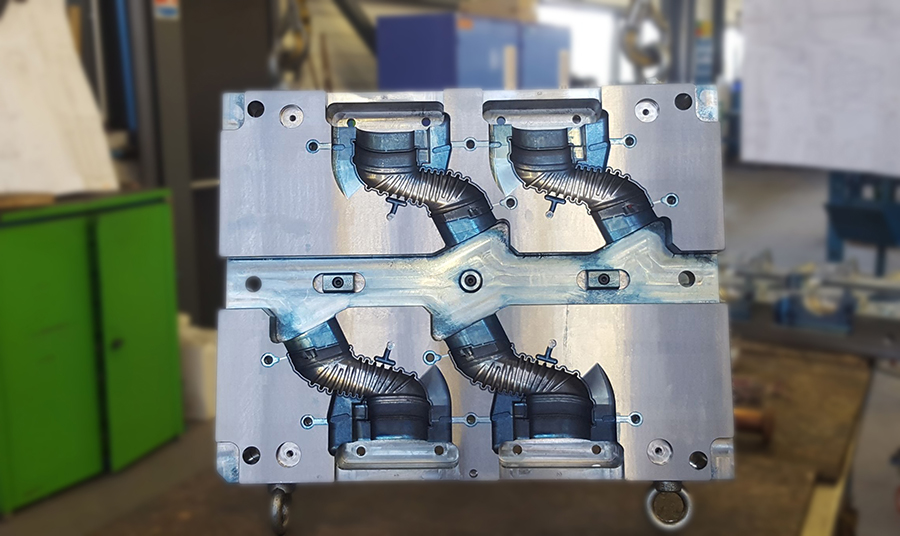

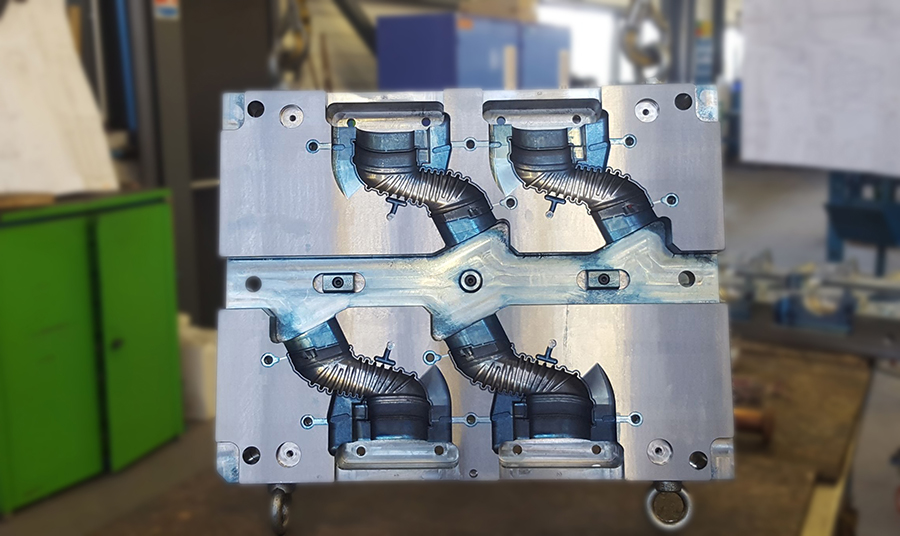

Dixence的主要业务是设计和制造模具设备,制造全橡胶粘合嵌件,以及塑料、金属和橡胶材质零件的模具。总经理GérardBeloeil说这些可以是不同等级钢材生产的注塑,压缩,调节转移或冷板模具; 经过预处理,硬化处理,并带有特殊涂层。

“The finished

parts are used to support gearboxes, engines,exhaust pipes, suspension systems,

engine sealings, and sound proofing.”

“成品部件用于支持变速箱、发动机、排气管、悬挂系统、发动机密封件和隔音。”

Working for

major suppliers of rubber parts around theworld, including France, Germany,

Spain, USA, UK, Russia, Turkey, Portugal,around 80 per cent of their output is

for automotive contracts, with the restgoing to customers in the energy,

cosmetics and railway industries. They haverecently made a REP V710 L 50 rubber

injection press available for validatingmoulds produced for the international

market. At the customers' request, mouldsare tested directly on-site at Dixence

avoiding any costly part returns…givinga real guarantee of quality.

Dixence服务于包括来自美国、德国、西班牙、美国、英国、俄罗斯、土耳其和葡萄牙等全球范围内的主要橡胶产品供应商。Dixence出口约80%的产品主要用于汽车行业,然后是能源、化妆和铁路行业。Dixence最近制造了一台REP V710 L 50橡胶注塑压机,用于验证为国际市场生产的模具。按照客户要求,模具直接在Dixence进行现场测试,避免任何昂贵的零件退货,真正保证加工品质。

About

three-quarters of the total production goes throughWORKNC, which Milling Sector

Manager Fabrice Provost says is fundamental toensuring that the moulds coming

off the machine tools are of the high precisionrequired. “The software’s 3D

functions are particularly important to us as weuse 3+2 axis machining, but

can’t program 3D manually。And since newenhancements have been made

for 2D operations such as manual and semi-automaticdrilling, weuse all 2D

toolpaths as they’re now more flexible.”

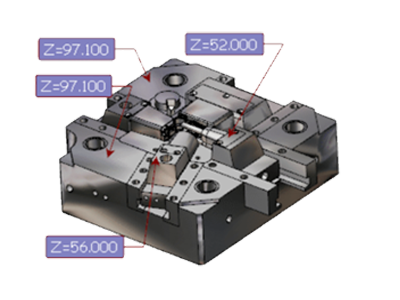

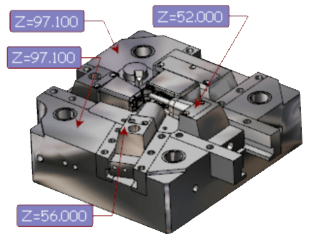

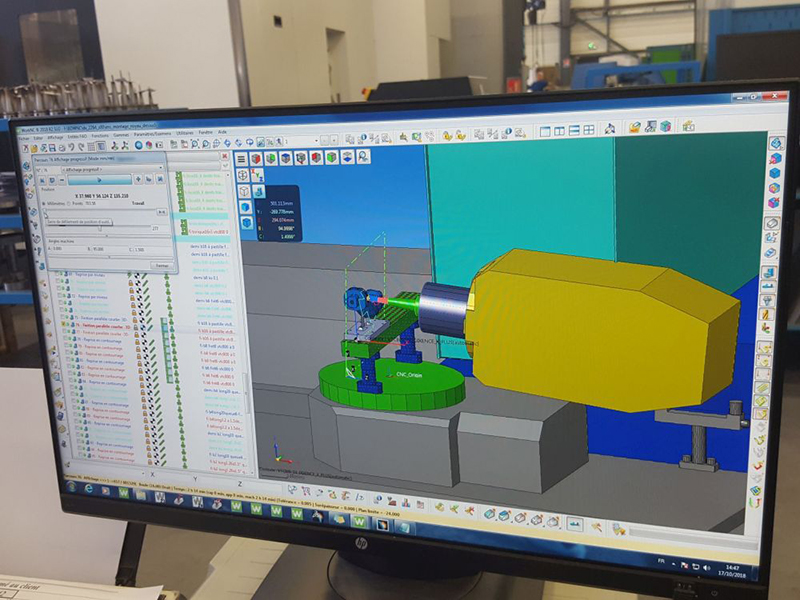

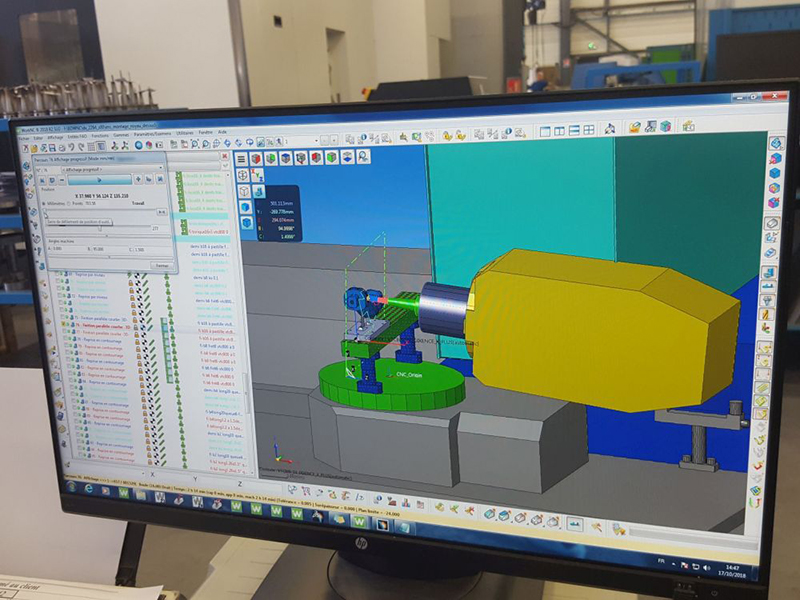

Dixence公司大约四分之三的产品都是由WorkNC完成,铣加工部门经理Fabrice Provost说WorkNC是保证成品精度的基础。“软件的3D功能对我们来说非常重要。因为我们使用3+2轴加工一样非常重要,但是不能手动操作3D。而自动2D功能提高后(例如手动和半自动钻孔)变得更加灵活,所以我们现在使用所有的2D刀路。”

WORKNC programs

three Huron and two Mazak verticalmilling centres, and two Mazak horizontal

palletised milling centres to produce the moulds and blocks, along withone HSM

milling centre for machining electrodes. “It’s this software/machine tandem

that allows us to achieve ahigh level of precision. The two go hand in hand.”

WorkNC驱动三台Huron(优龙)和两台Mazak(马扎克)立式铣床,以及两台Mazak(马扎克)卧式铣床生产模具和模块,以及用于加工电极的HSM铣床。“WorkNC无缝串联我们的机床使我们能够获得更高的加工精度。WorkNC和我们的机床是相辅相成的。”

Initially, the

mould CAD files are sent to theEngineering Department to check the project’s

feasibility and to determine thedifferent steps required to produce the tool.

Each part of the mould isidentified and listed, and a bill of materials is

inserted into WORKPLAN. Basedon that information, a set of documents is

generated, containing full detailsabout the mould, which will be used by the

purchasing document and shopfloor,allowing work to start on toolingelements.

Machining information aboutthe mould’s individual components means the milling

and turning team can assignthem to specific machines, and the files are opened

in WORKNC for the toolpathsto be programmed.

首先,模具CAD文件被发送给工程部门,以检查项目的可行性以及确定生产工具所需的不同步骤。识别和列出的模具的每一部分,并把物料清单插入至WorkXPLAN。在这些信息的基础上生成包含所有关于模具的完整详细信息的一组文件。这些文件将由采购和车间使用,使得整个工作由工具元素开始。关于模具各个组件的加工信息意味着铣削和车削团队能够将工作分配至特定的机器,并在WorkNC中打开CAD文件以编辑刀路。

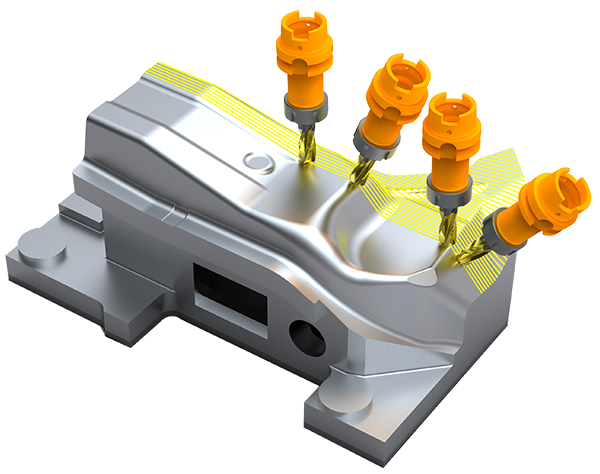

“Our programmers

often use standard WORKNC toolpaths suchas 3-axis Finishing and Contour

Remachining, which we find perfect forproducing a high-quality finish on curved

surfaces where there are no rightangles. And the comprehensive Global Roughing

functions are extremelyefficient, producing exactly the results we need.”

“我们编程人员常常使用标准的WorkNC刀路,例如三轴精加工和轮廓再加工,我们发现这些策略非常适用于无直角曲面,能够保证其高品质精加工。全面的全局粗加工非常高效,完全可以生产我们想要的结果。”

Even though some

parts they produce are similar, all mouldsmanufactured by Dixence are

different. Generally, they make two new mould toolseach week. They also produce

one cold runner block, which is positioned on themould, meaning they can

multiply the number of injection points forrubber-based components. “An

important feature of our process is that we designa cold runner block for each

project, so it is specific to each mould. Thisoffers a means of reducing material

costs for our customers, especially asrubber can’t be recycled.”

尽管有些部件相似,但是Dixence加工的所有模具都不一样。通常,Dixence每周会加工两种新的模具工具。Dixence也会生产一个新的冷流道块,用于定位在模具上。这说明Dixence能够成倍增加用于橡胶基部件的注塑点数量。

He says using

WORKNC has improved productivity andreduced errors on finished parts. “The

workshop functions round the clock,unsupervised during the night. With the full

range of WORKNC toolpaths, all ourmachines will soon be able to run during the

night, increasing productivityeven further over a 24-hour period.”

Fabrice Provost说使用WorkNC提高了生产力,减少了次品率。“车间24小时运行,晚上加工实现无人监督。全面使用WorkNC的刀路,我们所有的设备在晚上也能很快运行,从而在24小时内进一步提高生产力。”

Dixence also use

WORKNC’s sister brand, WORKPLAN as theirproduction control system. Gérard

Beloeil says they previously worked with anAccess database and paper-based

invoicing. “But with ever-increasing productionlevels we needed to avoid

duplicating data processing.”

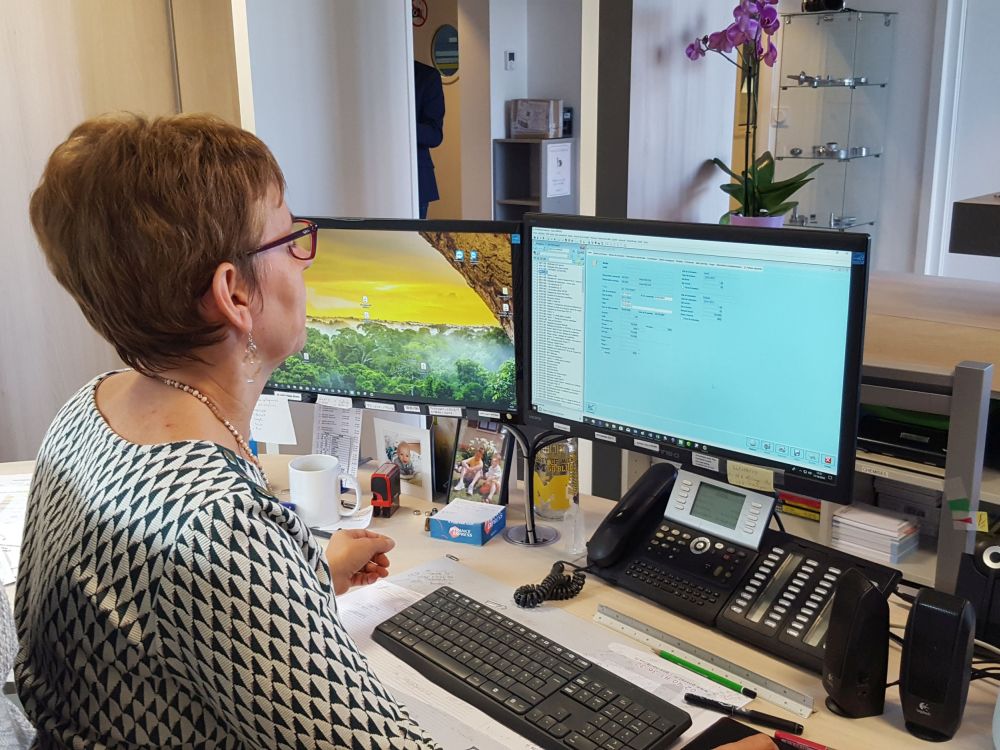

Dixence也使用WorkNC的姊妹品牌WORKPLAN作为他们的生产控制系统。Gérard

Beloeil说他们以前使用Access数据库和纸质版的发票。“但是随着生产水平的提高,我们需要避免重复的数据处理。”

With WORKPLAN

they consolidate allinformation, such as sales orders, purchase orders, time

management, deliverynotes and invoices, which is relative to each project.

“We’ve also got fulltraceability on purchasing, raw materials – including

quantity and cost – andpurchasing material for individual mould component,

which means we can makequick and accurate decisions.

Dixence通过WORKPLAN整合所有信息,例如与每个项目有关的销售订单、采购单、时间管理、发货单和发票。“我们还可以对采购、原材料,包括数量和成本,以及单个模具的采购材料进行全面追踪,这意味着我们能够快速而准确地做出决定。”

Anumber of

modules are particularly important to them:Job Management, which manages sales

related tasks and administration, fromorder confirmation through to

delivery…allowing easy access to allproject-related documents.

模块的数量对于Dixence而言尤其重要。工作管理,管理销售相关的任务和执行情况,从订单确认至发货,可以轻松访问与项目有关的所有文档。

The Purchasing

module includes their forecastpurchase budget based on the bills of material

directly imported into WORKPLAN,along with supplier quotations. “We can easily

monitor and control raw materialcosts and determine minimum stock levels.

采购模块包括了基于导入至WORKPLAN的采购清单预测的采购预算和供应商报价。“我们能够轻松监督和控制原料成本,以及决定最低的库存水平。”

The Time

Management function allows real timemonitoring of machine utilisation, the

status of outsourced tasks, and theremaining time required to finish a task.

“We often have similar tools toproduce, so we can simply look for a previous

project, copy it, and make thenecessary modifications.”

WORKPLAN的时间管理允许实时Dixence监督机器利用率、外包任务状态,以及完成一个任务所需的剩余时间。“我们经常使用类似的工件,所以我们可以轻松地查找以前的项目,复制它,并进行必要的修改。”

And thanks to

the Sales Activitymodule, order forms and invoices are generated with just a

few clicks, as allthe necessary information has already been fed into the

system. “This avoidsduplicated data entry errors, and means we can monitor

invoices daily, andchase payment to maintain a reasonable cash flow.”

得益于WORKPLAN的销售活动模块,只要点几下就能生产订单和发票。因为所有必要的信息已被输入在系统中。“WORKPLAN避免了数据重复输入错误,意味着我们能监控日常发票,以及追踪货款以保持合理的现金流。”

Concluding,

Gérard Beloeil says: “With all data aboutmaterial quantities, costs, and time

spent on tasks, recorded in WORKPLAN, wecan quickly calculate the cost budget

of our moulds, and progressively improveour profitability.”

总之,Gérard Beloeil说道:“所有关于材料数量、成本和任务花费时间等数据都会被记录在WORKPLAN中。我们能够快速计算模具成本预算,从而逐步提高我们的生产力。”

|

WorkNC

WorkNC