Amerimold, a two-day business trade show connects moldmakers, OEMs, and rapid product development professionals. Visitors to the WorkNC booth (428) can discover WorkNC’s Version V 22 which provides revamped 5-axis strategies due to its new ergonomics and improved programming possibilities. The 5-Axis module offers greater flexibility, simplicity of use, and enhanced machining capabilities.

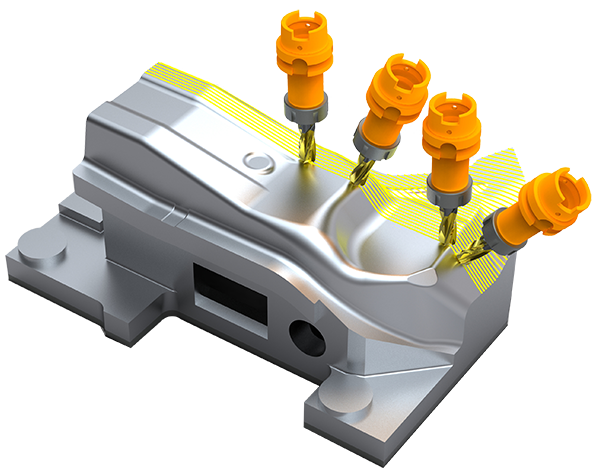

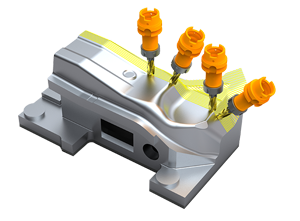

Mold & Die 5-Axis Machining

As more companies are investing in 5 axis technology for milling mold & die components, a growing numbers of 5-axis machining centers are becoming available. As many advanced technologies reach the market, new entries bring innovation that provide high functionality for lower costs.

Simultaneous vs. Positional

Discussions involving 5-axis machining usually include the definition of simultaneous and positional machining and what they mean. Five-axis simultaneous machining involves the rotation and linear movement happening at the same time (simultaneously) during the milling process.

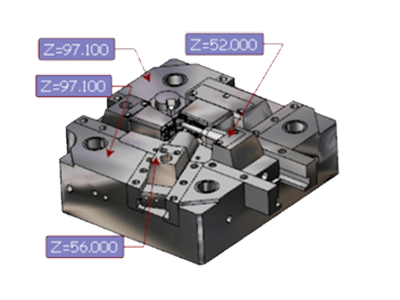

Five-axis positional refers to 3+2 machining, this occurs when the mill rotates in an angular position and mills with linear moves only. The part does not rotate while during the milling process.

From a practical standpoint, most all 5-axis simultaneous milling machines can also do 3+2 axis machining. However, not all 3+2 axis milling centers can do 5-axis simultaneous.

Five-axis for Moldmaking and Diemaking:

Five- (3+2) axis machining has been common in mold- and die-machining for some time, especially when programming slides. According to Jeff Jaje, Marketing & Business Development Manager, WorkNC, there are several reasons why a business would choose to invest in this technology, such as:

-

Being able to mill deeper into a part easily, allowing the end-user to use fewer, or no, EDM burning operations.

-

Having the capability to mill more of the part with shorter tools, which will increase tool rigidity, reducing vibration and deflection, providing better surface finishes and shorter milling times.

During the show, end-users will be able to see demonstrations on the benefits of 5-axis machining for mold- and die-machining, as well as the benefits of the Auto-5 automatic machining module.

WorkNC:

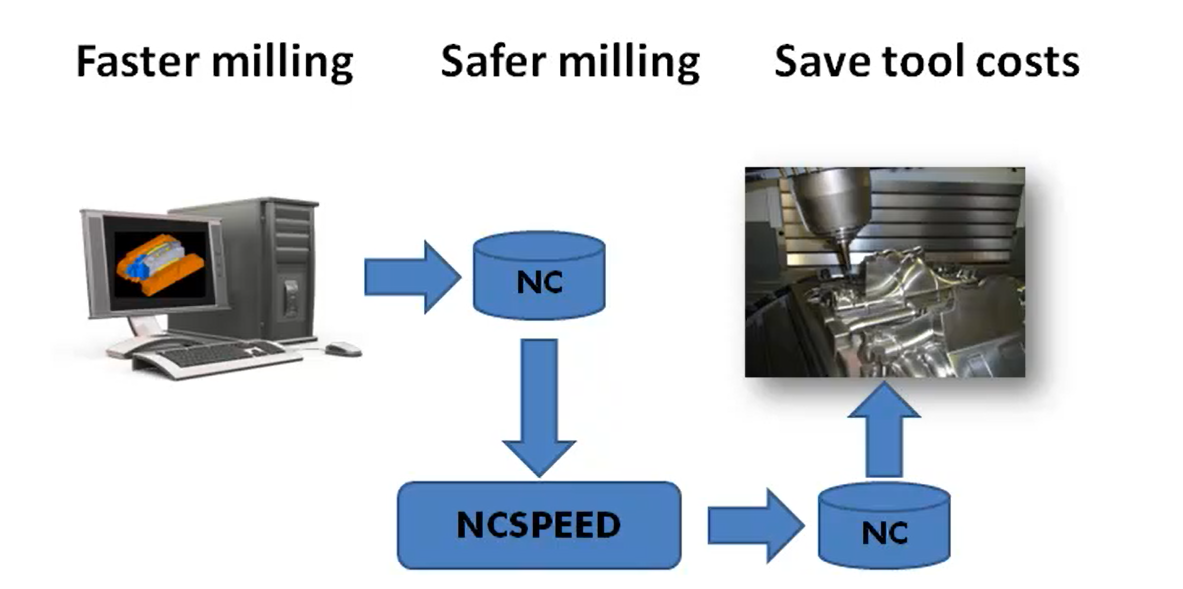

WorkNC increases the ability to assist CNC manufacturing centers or job shops to run “lights out” with enhancements to their dynamic stock model. Utilizing this technology allows the software algorithms to know the condition of the stock during cutter-path calculations. This allows the cutter-path to have consistent cutter engagement which extends tool life while reducing air time. Overall, it provides high levels of confidence in the reliability of the roughing and finishing cutter-paths, allowing the milling machines to run unattended.

Drop by and visit us Booth 428.

|

WorkNC Industry ...

WorkNC Industry ...