Automotive

Ever since the 80's WorkNC has been proving its effectiveness for automotive applications time and time again...

Major vehicle manufacturers have reported significant reductions in lead times and improvements in quality, thanks to WorkNC. WorkNC's ease of use, calculation speed, the ease with which it can be integrated with existing systems, and its consistent rules based manufacturing methods are some of its key advantages.

Down the supply chain, WorkNC also delivers significant benefits. Companies specializing in cubing models and vehicle sized model stacks need control over the direction of machining as this can have an effect on the appearance of the finished product. Additionally, in many cases hand finishing is unacceptable, making the reliability and versatile of WorkNC particularly relevant.

Within this sector, reliance on and interpretation of CAD data is well established. The ability of WorkNC to manipulate designs and prepare them for production is crucial for success.

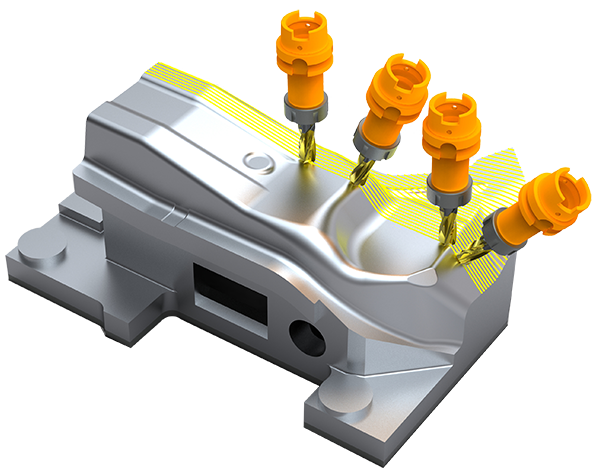

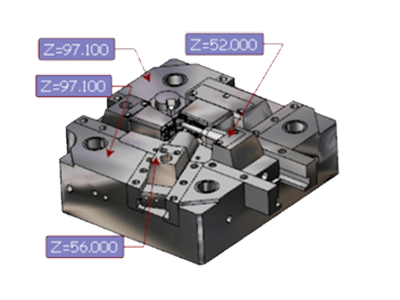

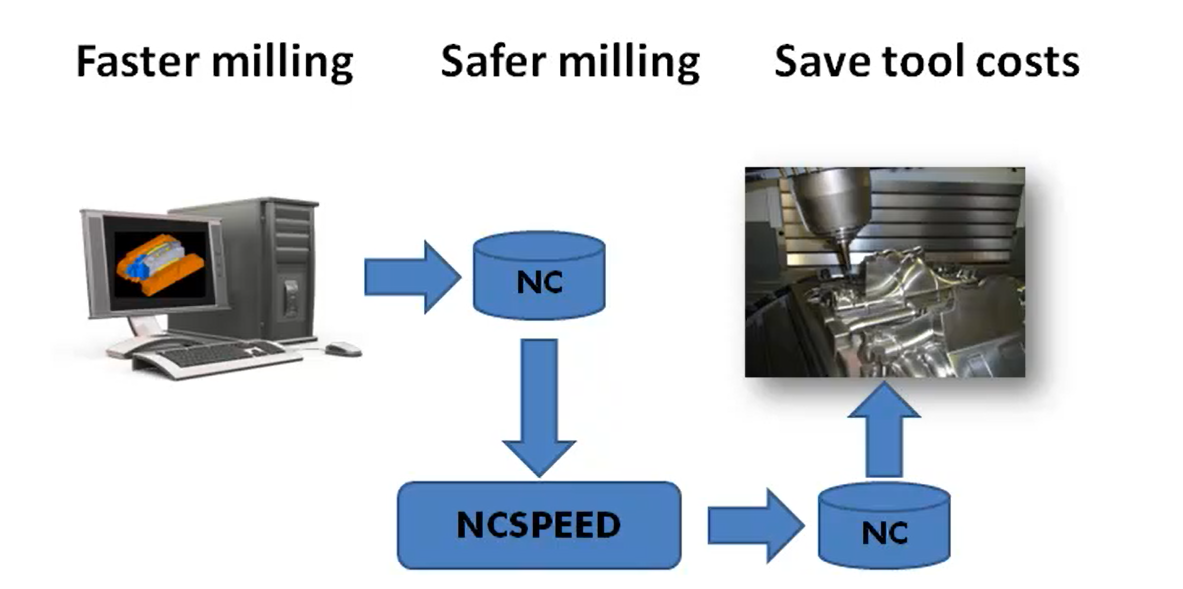

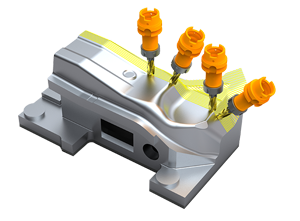

Tool and moldmaking feature heavily in the automotive industry. WorkNC's CAD data management, routines to machine hard materials, and techniques for maximizing cutting speeds and minimizing wasted machine movements all contribute to faster production and higher productivity.

This can be further enhanced by WorkPLAN Solutions, the ERP manufacturing management platform for custom manufacters. These software packages help companies to control key business drivers including quotations, costs, production and quality in order to achieve optimum profitability.

WorkNC Industry ...

WorkNC Industry ...