NCspeed

optimising the Die Surface milling process for a large Stamping Die

Evaluation

test in Dagenham Tool&Die Ford Motor Company

1.

Summary

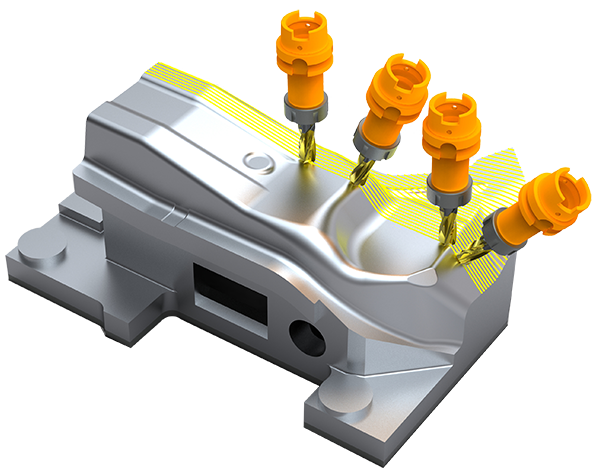

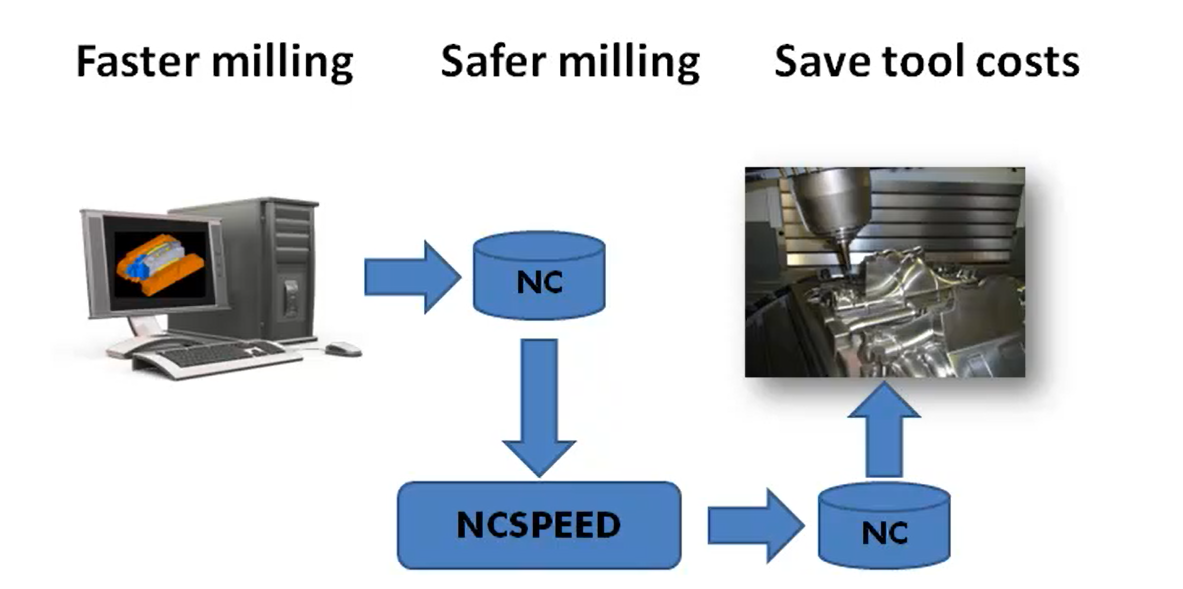

The software NCspeed from FORMTECGmbH is an optimisation system for

NC-programs in the field of die and mould making process. NCspeed acts as a

post-processor on standard MCD output and adapts the programmed feed rate to

the actual cutter engagement conditions. The software reduces the feed rate in

areas, where the milling tool has to cut high volumes of material whilst in

uncritical areas with less or none material the feed rate is increased

significantly. This results in total machining time savings of about 20% and more

depending on the cutting strategy while achieving a better process stability at

the same time with no manual intervention from the machine operator.

In this evaluation pilot at Ford's Tool&Die shop in Dagenham more

than 40% machine time savings have been realised for the pre -finishing milling

operations. The predicted improvement of the milling process stability could be

proved in reality which may allow the operator to securely run more than one

milling machine, a contribution towards man-less machine aperation.

2. Test environment

The MCD output of Jaguar's X400 lift gate inner punch die unit was

optimised with the NCspeed software. The previous NC programming was done with

a CAM- System using alltaday's commonly used strategies as roughing-in-plane,

copymill and rest material in 3and 3+2 axis mode with toroid and ball end

cutlers. The surface geometry of the part is symmetric and therefore one half

of the workpiece could be milled with NCspeed and the other conventionally,

letting the machine operator control the mill's feed. This enabled US to

compare the actual milling time.

3.

Test results

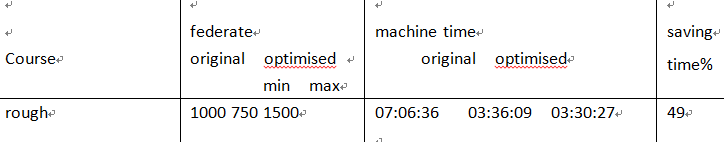

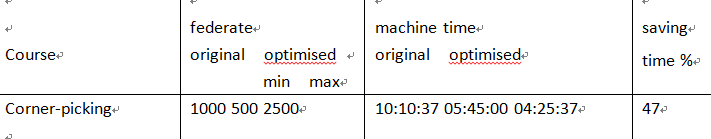

3.1. Roughing

The selected CAM-strategy for roughing was roughing-in- plane. This

commonly used method with its toroid cutters usually

uses the conventional climbing option which generally results in a higher degree

of air cuts and approaching/retracting movements

with a total increase of machining time. As

NCspeed simulates the actual material stock condition, air cuts are speeded up

and reduced (67 vs. 147 meter) and the cutting force on the cutter is kept constant

by controlling the feed rate accordingly. In total, the milling time of this NC

operation is decreased, results are shown in the next table.

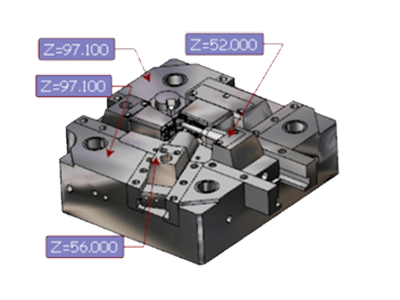

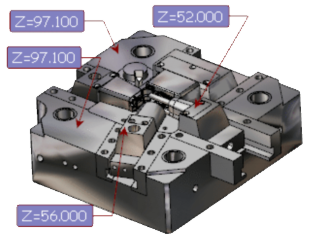

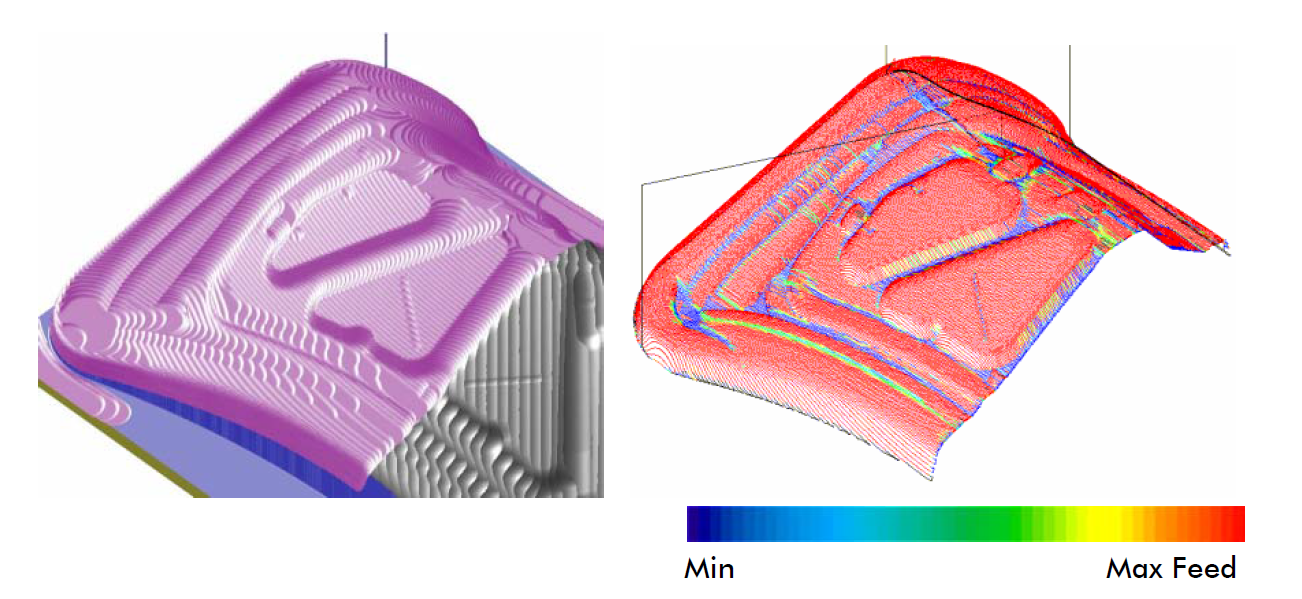

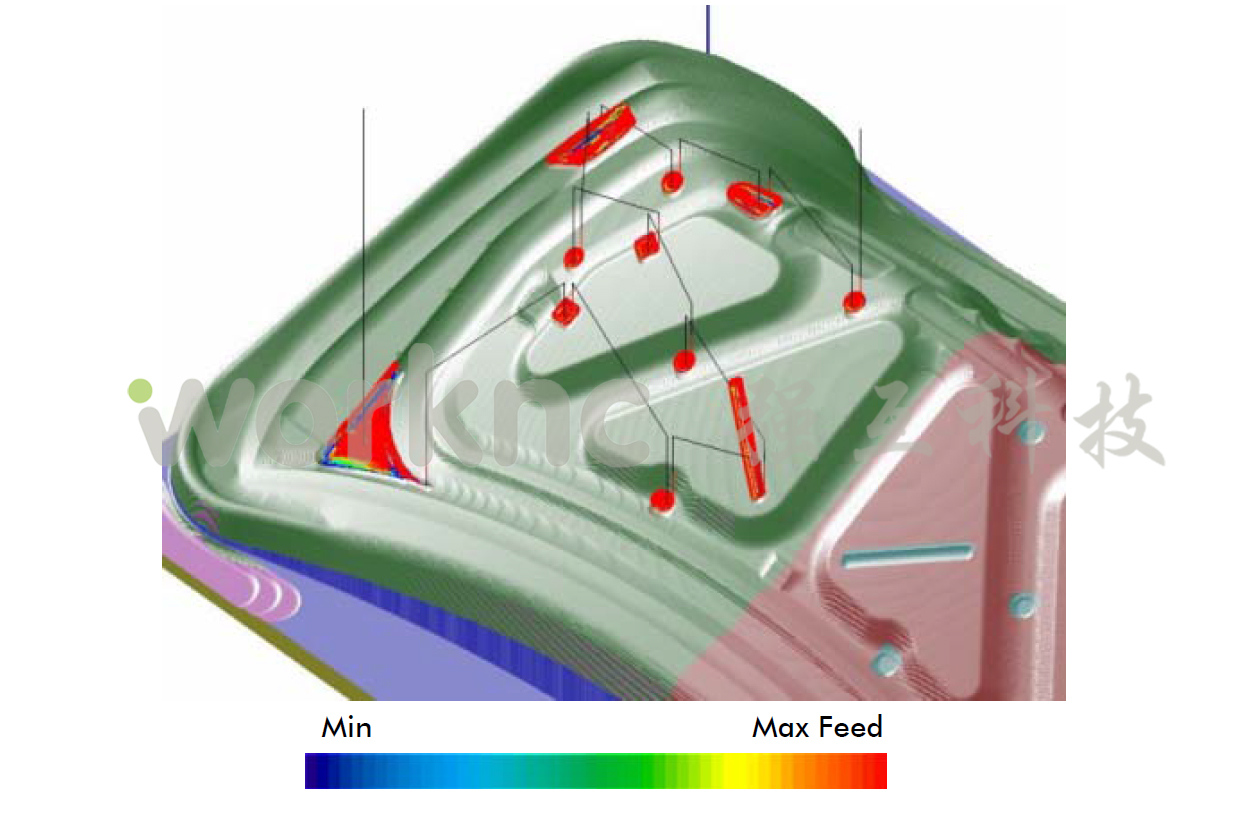

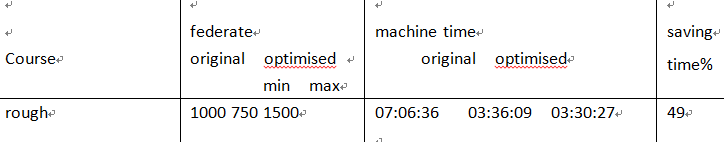

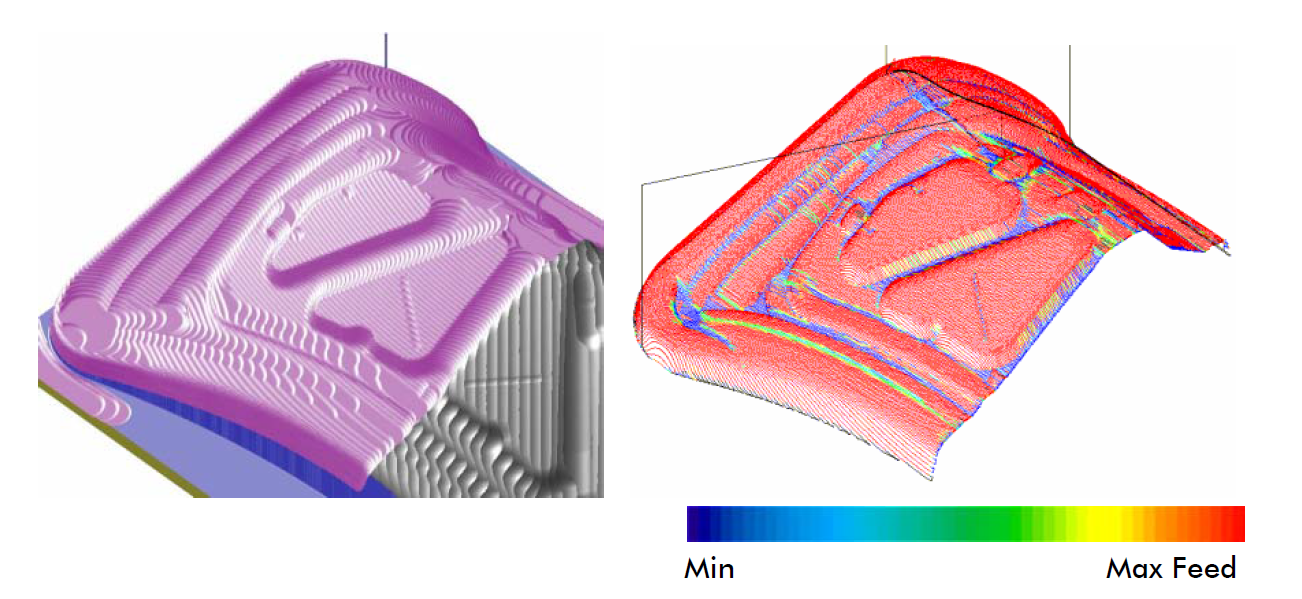

3.2. Semi-finishing

The first roughing process with its large cutter usually leaves much

material in areas where the cutter can not plunge in. The NC programmer must

take notice of this situation and plan the following milling strategies

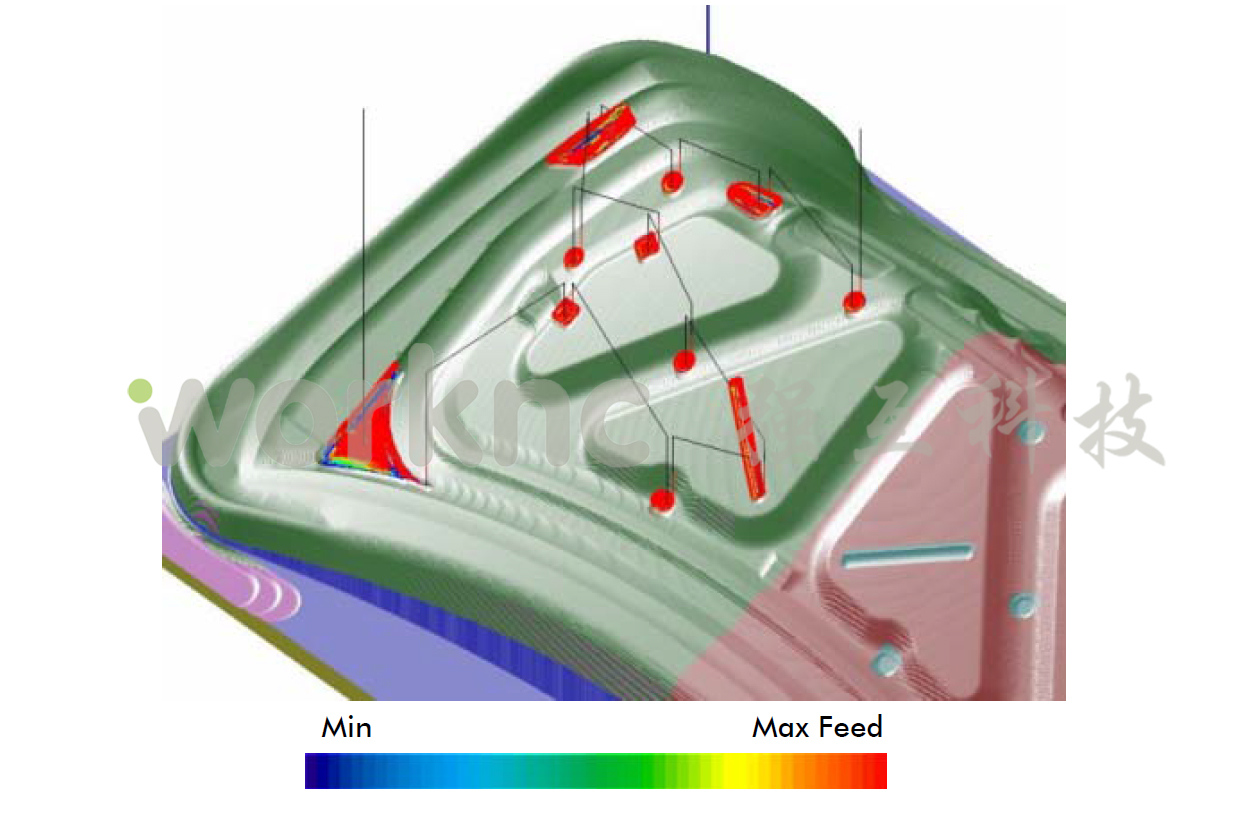

accordingly. As NCspeed simulates and displays the actual material situation it

is also a valuable tool for the NC programmer to plan and set up the next NC

operations as can be seen in the left picture.

Based on the calculated material stock NCspeed simulates the cutting process

and adjusts the machine feed to keep the cutter's stress as constant as

possible. Blue coloured areas in the right picture indicate critical engagement

conditions of the cutter with low feed rates detected and automatically

adjusted by NCspeed. Specially all grooves and corners in the left picture are

critical spots. Compared to the machine operator who dsiminishes the feedrate

at the controller's level manually the simulation with NCspeed guaranties a

saver process and an efficiency improvement of 59%.

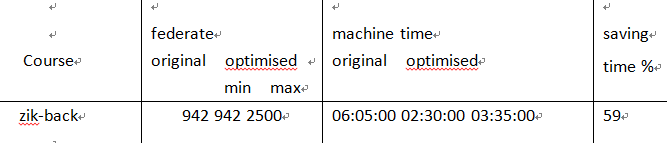

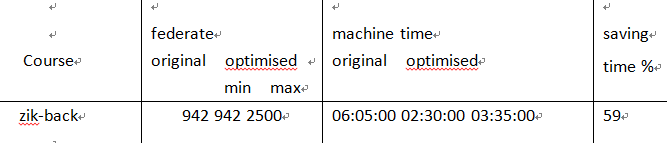

3.3. Restmaterial Clean-up

To get a uniform material offset on the die surface and to be prepared

for the final High-Speed Cutting the rest material along grooves and convex

corners must be cleaned. The CAM-System calculates the affected regions and

delivers the cutter paths. NCspeed simulates the cuter's stress situation and

adjusts the feed rates.

The savings in machine time are again tremendous. With the NCspeed

optimised NCprogram the machine operator had not to approach the workpiece

slowly and carefully and the NC programmer also encouraged him to push the

start button and let the program run because he already checked and verified

the milling process during the computer simulation.

3.4. High Speed Finishing

The NC programmers experience in defining appropriate milling strategies

and the ability of today's CAM systems yield to a

very proportional material of set of usually 0.2mmacross the workpiece's

surface. Therefore generally speaking there is nothing or very little that

can be optimised with NCspeed in this final High Speed Cutting operation.

3.5. Machining Time Totals:

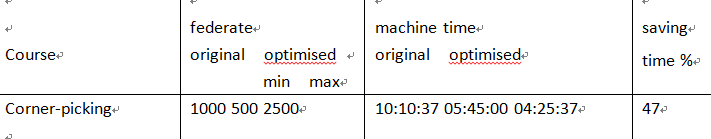

|

course

|

federates

|

machining time

|

Savings

|

|

original

|

optimized

|

original

|

optimised

|

|

min

|

max

|

time

|

%

|

|

profiling

|

|

|

|

0:10:44

|

0:10:44

|

00:00:00

|

0

|

|

roughing

|

1000

|

750

|

1500

|

7:06:36

|

3:36:09

|

03:30:27

|

49

|

|

zick-zack

|

942

|

942

|

2500

|

6:05:00

|

2:30:00

|

03:35:00

|

59

|

|

zick-zack front

|

|

|

|

1:08:00

|

1:08:00

|

00:00:00

|

0

|

|

zick-zack back_

|

|

|

|

0:49:00

|

0:49:00

|

04:25:37

|

0

|

|

corner picking

|

1000

|

500

|

2500

|

10:10:37

|

5:45:00

|

00:00:00

|

43

|

|

zick- -zack precut

|

|

|

|

0:15:00

|

0:15:00

|

00:00:00

|

0

|

|

finish top

|

|

|

|

3:55:12

|

3:55:12

|

00:00:00

|

0

|

|

finish bottom

|

|

|

|

8:27:36

|

8:27:36

|

00:00:00

|

0

|

|

finish left

|

|

|

|

1:27:34

|

1:27:34

|

00:00:00

|

0

|

|

|

|

sum

|

39:35:19

|

28:04:15

|

11:31:04

|

29

|

WorkNC Industry ...

WorkNC Industry ...