Fast moving, prestigious and cutting edge aptly describes the motosport industry...

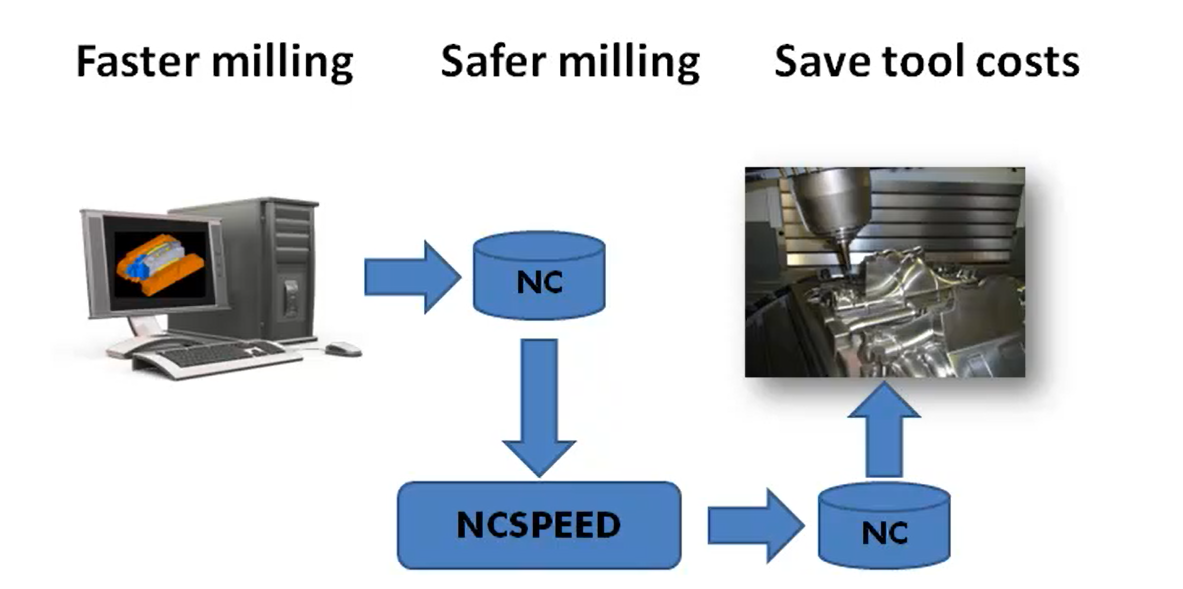

WorkNC provides companies supporting this sector with the ability to quickly respond to rapidly changing requirements and at the same time easily handle the most complex machining tasks.

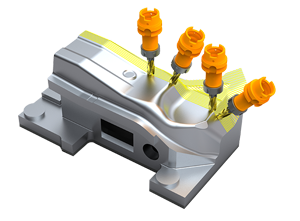

5-axis machining of composites and models, high speed machining of hard materials, and cutting of deep cavities and intricate shapes are typical of these. WorkNC has dedicated 5-axis toolpaths, plus its unique Auto 5 function which automatically transforms 3-axis cutterpaths into 5-axis. High speed machining with troichoidal movements makes cutting hard materials simple, extending tool life and producing a high quality surface finish.

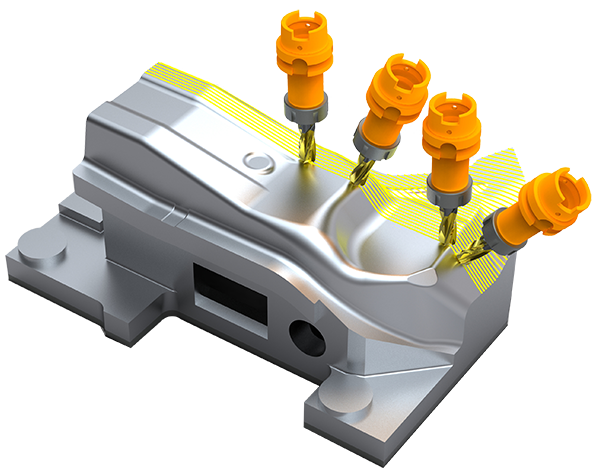

Collision avoidance for the tool and tool holder makes it possible to cut the deepest cavities with confidence, while the ability of the software to dynamically update the stock model allows very small tools to be used without the risk of breakage.

Engineers in motor sport are highly capable, and have multiple demands on their time and expertise. The easy, automated programming in WorkNC simplifies their workload, enabling them to optimise the use of their time which will, in turn, ensure that quality standards are maintained and delivery targets achieved.

Creating rapid and accurate quotations for the specialist parts required by motor sport companies, and the control of costs and progress, is crucial to profitable operation. WorkPLAN Solutions, the ERP management solution is geared towards custom manufacture and track the production process. Historical information and real time reporting offers managers the tools to monitor key business drivers, using factual and up to date information, enhancing performance in all areas of their business.

WorkNC Industry ...

WorkNC Industry ...