Why WorkNC?

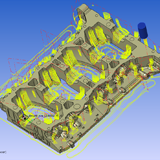

Mold and die makers, toolmakers, pattern makers, prototype makers, press and stamp toolmakers have long been acquainted with the powerful functionality of WorkNC.

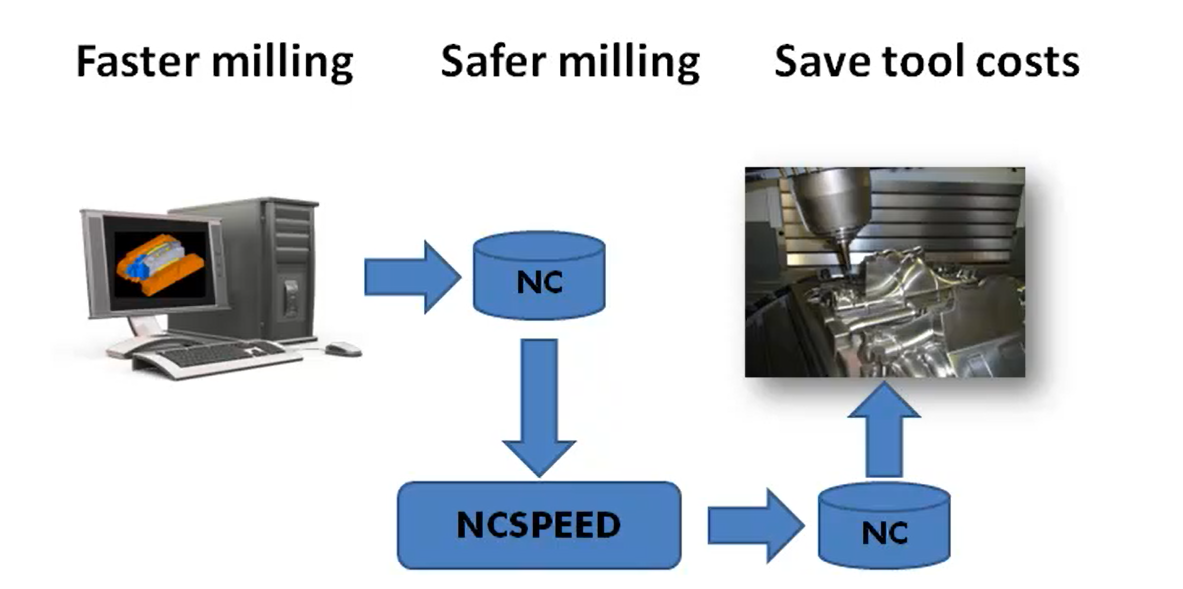

The easy to use, high performance CAD/CAM solution for machining complex geometries, WorkNC combines ease of use, fast calculations, toolpath reliability...

WorkNC increases your productivity in a world where the competition is fierce and helps ensure market gains in largely diversified sectors of manufacturing : automobile, aeronautics, household equipment, consumer goods, toys, sports and leisure articles, packaging, glassware, jewellery, optics, musical instruments, shipbuilding, prosthesis, ...

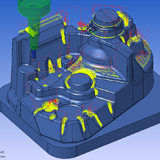

The Automatic Solution

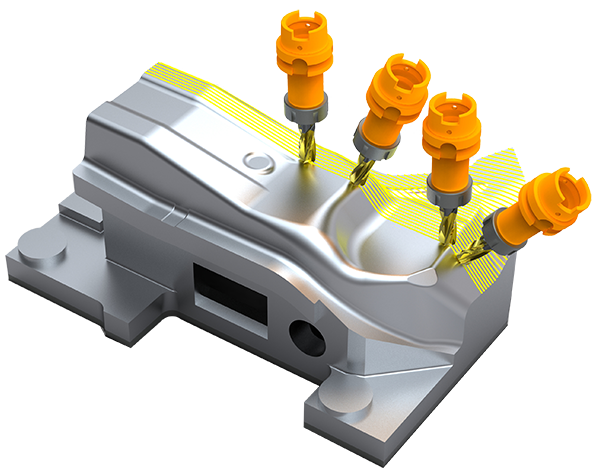

WorkNC is the closest system to "single button" programming and has several automatic toolpath types to fit your every need such as Roughing, Finishing, Optimization, Remachining, Contouring, Curve Machining and Hole Boring.

WorkNC takes the guess work out of your cutter path generation because it's AUTOMATIC. Just enter a few basic parameters to get your job running and the automated CAM software takes care of the rest. WorkNC provides its own lightening fast graphic toolpath editor and generic post processor generator program.

You don't need to be a computer expert to use WorkNC.

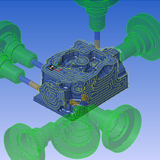

Increased Productivity

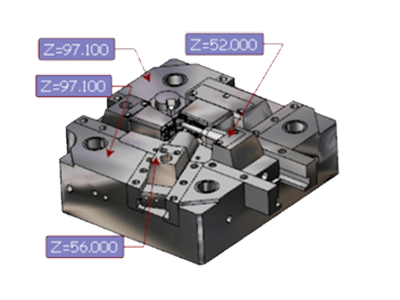

Significantly reduce preparation times and generate consistently optimized toolpaths. WorkNC eliminates any time wasting tool movements on the machine to considerably reduce machining times. Make the most of your know-how by saving projects in machining sequences and re-use them time and again on similar jobs.

Reliability

By employing the most advanced control technologies, WorkNC guarantees the upmost reliability of your generated toolpaths. Furthermore, WorkNC ensures the highest levels of safety when using High Speed Machining strategies.

Ease of Use

You will be won over by WorkNC's ease of use and refined ergonomics. With its user friendly interface and simple parameterization, WorkNC is perfectly at home either in the engineering office or directly on the shopfloor.

Batch Mode Calculation

Most other CAM software solutions lock up the entire user interface on a given job. WorkNC is so flexible you can work on multiple jobs simultaneously, even while calculating cutterpaths, and save considerable time.

High Speed Machining (HSM) Optimized

You will appreciate the reliability of WorkNC toolpaths in a High Speed Machining environment. All the functions required to optimize the investment made in expensive HSM machines are included as standard features in WorkNC.

Maximum Autonomy

With WorkNC and it's integrated CAD module you have the necessary tools at your disposal to economically produce any type of tooling equipment.

During the machining preparation phase you will find it easy to add protective surfaces, define drilling points, mask holes, recover curves and rest material boundaries to make additional electrodes etc...

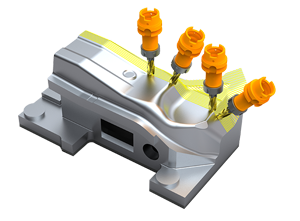

Fast Calculation Times

WorkNC supports task threading and parallel processes on multi-core processors. What does this mean for WorkNC users?.....

* Task Threading: certain cutterpaths will run multiple threads. That means individual portions of the cutterpath will be calculated at the same time. Computers with multi-core processors will run those threads individually, on separate cores, decreasing calculation times. It is not just cutterpaths that can be multi threaded, but other calculations as well. For example, Auto 5 will be able to take advantage of this technology for faster calculations.

* Parallel Processes: multiple cutterpaths in the workzone can be run simultaneously, as long as one is not dependant on another. For example, a Planar Finishing can run at the same time as a Z-Level Finish, since one is not dependant on the other. However, a Global ReRough may need to wait on a stock model update before calculations start. Parallel processing will allow you to calculate more cutterpaths faster than ever before, taking advantage of your multi-core processors.

This is what one WorkNC user had to say..

“…the difference, without any fear of exaggeration, is like going from a piston engine to a jet engine.

I make complex high volume injection moulds and whereas before I could go and make a cup of tea whilst the computer was chomping out the code for say a large intricate electrode now I can't even get the kettle on! It's that big a difference…..”

WorkNC Industry ...

WorkNC Industry ...