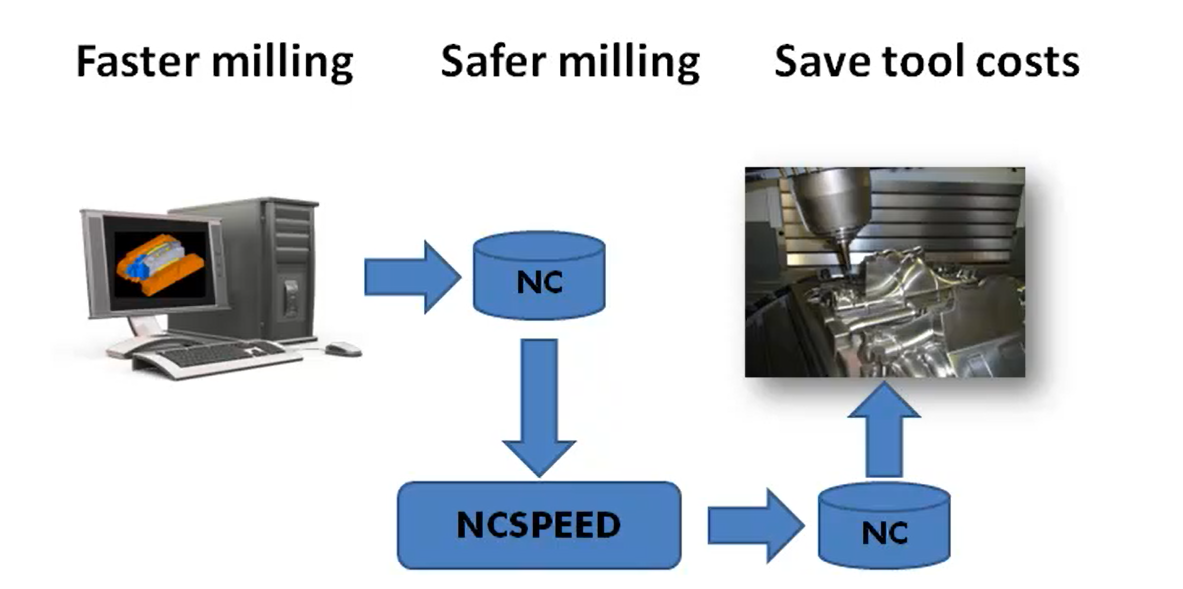

Speed up with new Feedrates

Your daily business is to manufacture complex dies and molds. To be fast and

cost-effective, you need seamless integration of CAM system, machine/controls

and milling tool. We help you to tap into the unused potential of your

manufacturing equipment. Continuously adjusting the feedrate to varying engagement conditions allows better operating conditions for both

machine and tool. Milling times can be reduced by up to20%. This

translates into real cost savings and substantial lead time reductions.

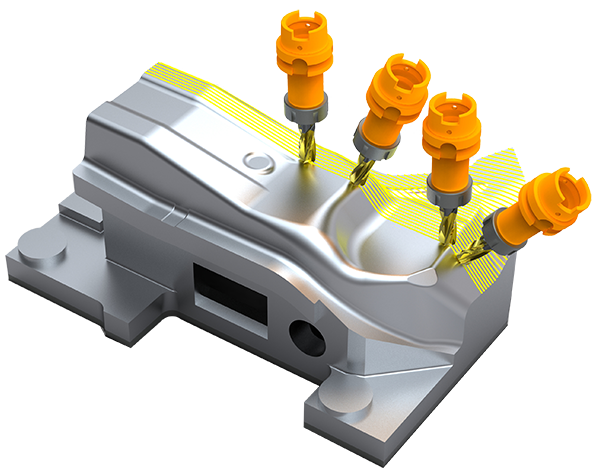

NCspeed is a software system for the simulation of 3- and 5-axis milling processes.

The milling process is optimized with regard to machining time and process

safety. Furthermore the checking of toolpath is possible.

Working method

Based on a volumetric simulation NCspeed can analyze the

material removal process during milling. This principle enables a visual

checking of the milling process. For this purpose NCspeed offers a shaded

visualisation of the continuously machined geometry. Due to this, it is

possible to detect faults in the NC-program before a machining crash occurs.

The optimisation component of NCspeed calculates the material volume to be cut by

the milling cutter and adjusts thefeedrateto the

actual engagement conditions. The more material is to be cut, the slower is

the feedrate and vice versa. Based on this

principle a new feedrate profile is generated.

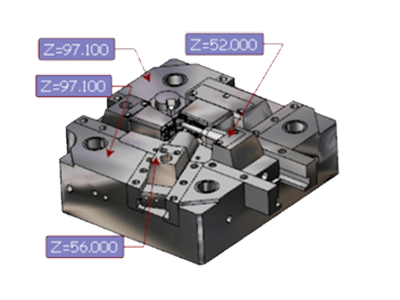

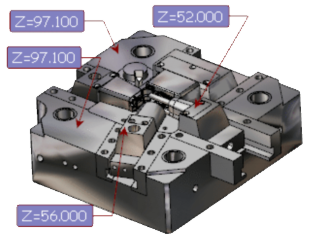

NCspeed works as a postprocessor. A toolpath is reading, additional feedspeeds are inserted and the optimised program is

written back. All common toolpath formats like DIN/ISO,Heidenhain conversational and APT- can be used. The toolpath generated by NCspeed are of the same dialect

as the original ones.

What is NCspeed NOT

NCspeed is no CAM-system. You can optimise existing toolpath but youcan not generate completely new toolpath. Basically

NCspeed inserts new feed commands. The geometry of milling paths is not changed.

The milling machine will move the same way as with the original program. The

only exceptions to this are the air cut removal and the optimisation of the

path connections.

When should NCspeed be used

The usage of NCspeed is recommended whenever the maximum usable feedrate in the milling process is limited by the cutter.

E.g. the machine can perform a feedrate of 10000 mm/min

with sufficient accuracy. The tool is only capable of performing a feedrate of 2000 mm/min to avoid tool damage in critical areas.

In this case the maximum feedrateis limited by the

tool and NCspeed offers a significant optimisation potential.

If the machine is already working at the feed limit, the feedrate optimisation can offer no (or only small) advantages. Presumed, you are

machining an easy to cut material, the maximum feedspeed of the machine is 10000 mm/min and this feedrateis

actually chosen. Because NCspeed cannot change the physical capabilities of

the machine, the optimisation potential will be low.

There are three exceptions:

-

The usage of very small cutters. In this case the danger of tool break

is present. NCspeed can increase the process reliability significantly by

avoiding of tool break.

-

Usage of long, thin cutters. This can lead to high tool deflections,

resulting in unsatisfactory accuracy. NCspeed can minimize the cutting forces

avoiding larger tool deflections.

-

Chatter vibrations, which often occur, when using long, thin cutters.

NCspeed recognize typical situations where vibrations can occur.and adapts the feedrate to avoid

these vibrations.

Basically there are optimisation potentials, unaffected by the

machine and workpiece material, by using the NCspeed features optimize air

cuts and optimize path connections.

WorkNC Industry ...

WorkNC Industry ...