Main Modules

Integrated CAD & Analysis functions

-

Standard translators : IGES, DXF, STL,

-

Direct translators: UGS®, Catia® V.4/V.5,V.6 Parasolid® ...

-

Mold Analysis Functions,

-

3D surface modeling functions,

-

Advanced intelligent surface morphing for filling simple or complex cavities,

-

Automatic 2D Features recognition and cycle definition for drilling, counterboring, reaming, tapping...

-

Automatic mold and die core separation.

High performance CAM functions

-

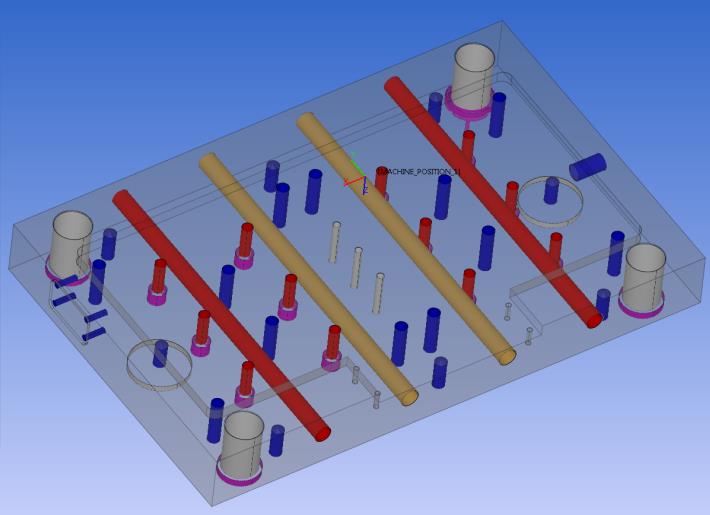

Automatic geometry and machining zone detection and management,

-

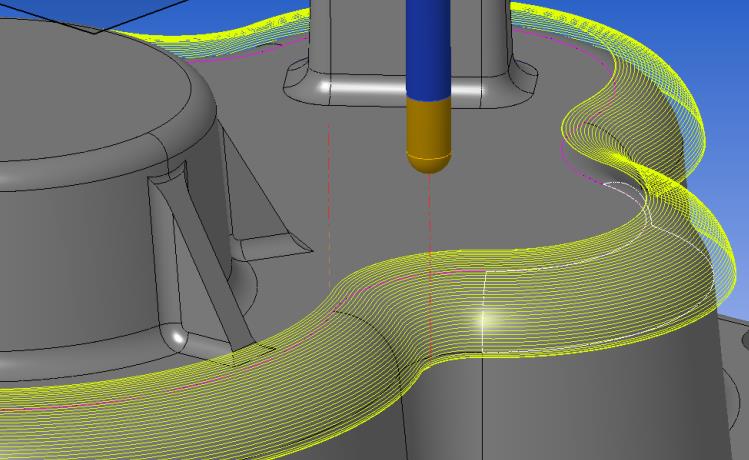

Specific fluid and progressive toolpaths designed for High Speed Machining,

-

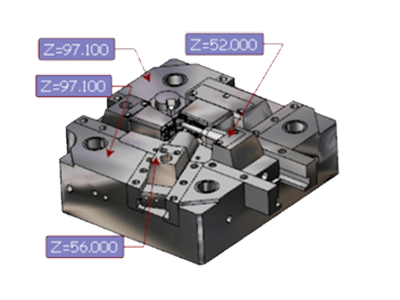

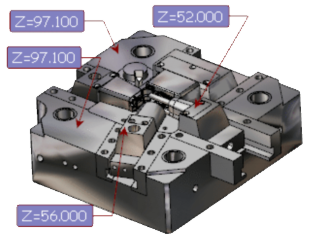

Full user stock definition (block, CAD, STL),

-

Dynamic 3 and 3+2 stock Management (Real time toolpath updated),

-

Complete tool and holder collision check with automatic stock update,

-

Powerful toolpath editor,

-

Virtual 3D machine representation and machining simulation (dynamic editing of points and vectors),

-

Powerful tool and holder library (holder components managed),

-

Automatic HTML workshop documentation,

-

User predefined machining sequences for automatic machining,

-

Machining from STL files and point clouds,

-

Batch mode calculations,

-

Comprehensive postprocessor generator (NURBS, cycles, circular interpolation...).

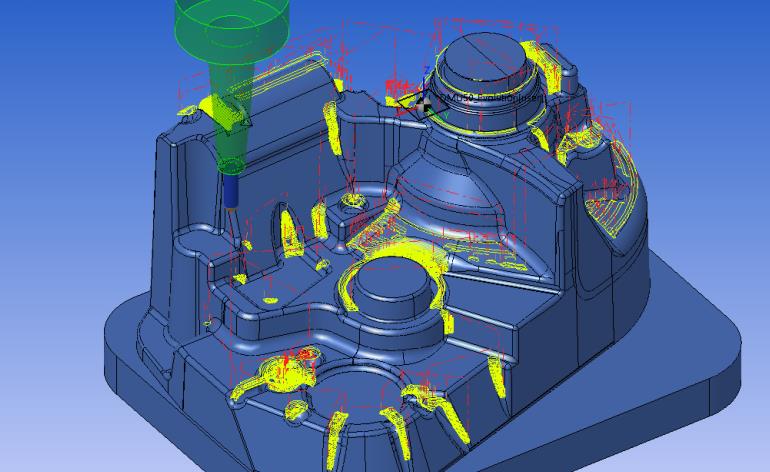

Powerful and optimized roughing toolpaths

-

Global Roughing and Re-roughing toolpath designed and optimized for HSM machining,

-

A range of specific toolpaths with trochoidal, spiral or plunging movement

-

Roughing strategies use the automatic Tool and Holder collision avoidance check with an automatic update of the stock,

-

Automatic calculation and machining of rest areas based on dynamic stock.

Powerful and optimized finishing toolpaths

-

A wide range of Finishing toolpaths optimized for HSM machining,

-

Z Level finishing, Planar finishing, Flat surface finishing, Contour finishing, Edge finishing,

-

3D Display of rest-material areas,

-

Automatic 5 Axis conversion possible

-

Re-machining toolpaths enable automatic rest material machining with increasingly smaller tools.

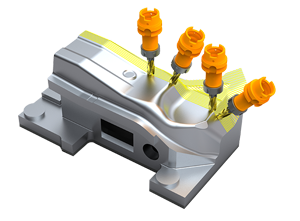

Intelligent 2 and 2.5 Axis toolpaths

-

Range of 2 and 2½-axis strategies,

-

Pocketing, Contouring, Curve machining, Engraving, Rib machining, Facing, Drilling, tapping ...

-

Automatic Drilling Module,

-

Automatic features detection, Pre-defined drilling sequence selection, Automatically generated drilling operations, Deep hole and intersecting hole drilling management,

-

Customized Postprocessor.

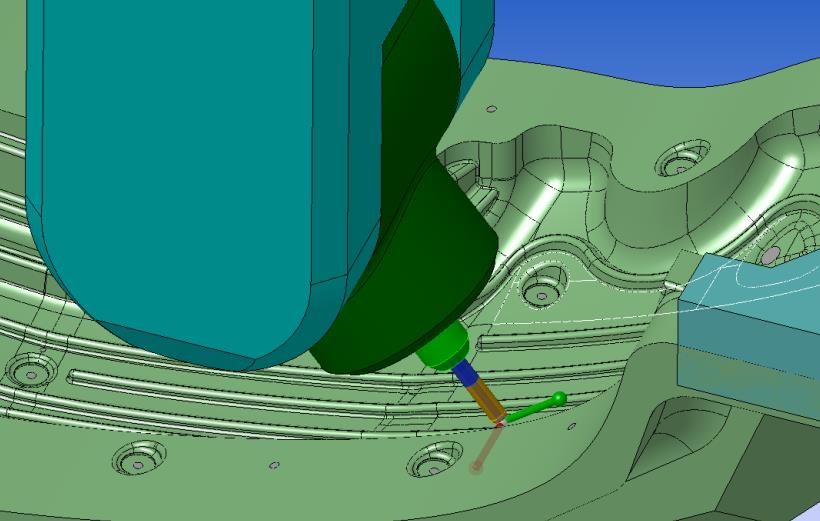

Automatic & Simultaneous 5 Axis toolpaths

-

Automatic 3 to 5-axis toolpath conversion - Auto 5,

-

Wide range of Simultaneous 4 and 5 Axis toolpaths,

-

5 Axis Rolling, Planar finishing, Spiral Blade, Impeller, Tube, Laser ...

-

Collisions detection and machine limits management

Other Features

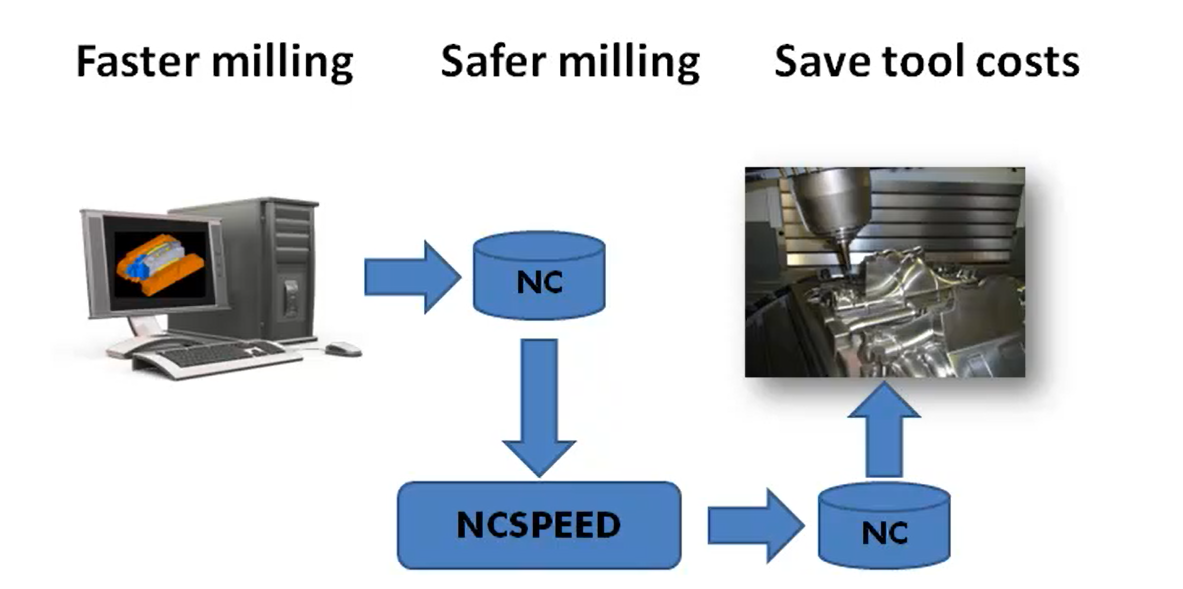

WorkNC is renowned for its automatic functions and supreme ease of use.

WorkNC's automated functions allow users to generate toolpaths easily and automatically.

Automatic Geometry Preparation

-

Unlimited size and number of surfaces

-

Detection of non-machined areas

-

Handling of twisted and triangular surfaces

-

Handling of discontinuities

-

Handling of superimposed surfaces

-

Linking of all surface elements

-

Collision checking on surfaces edges and corners.

Batch Mode Calculations

As you may know, most other CAM softwares lock up the entire user interface on a given job. WorkNC is so flexible you can work on multiple jobs simultaneously.

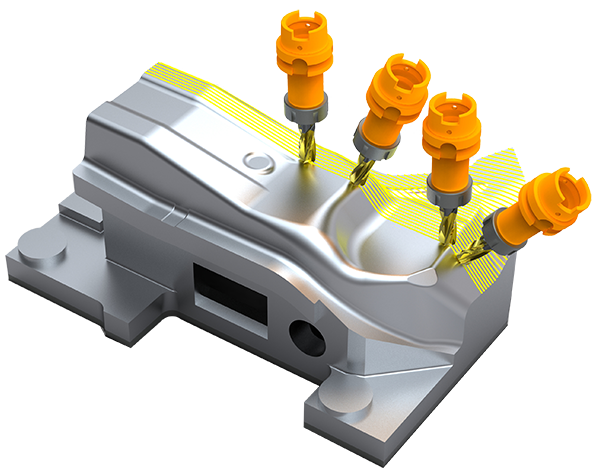

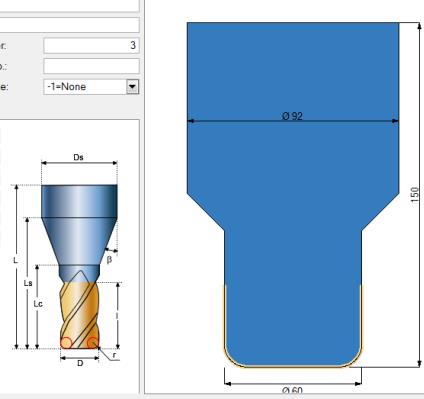

Tool Holder Collision Detection

Create you tool holder library dynamically in WorkNC. Use defined tool holders for checking collisions between the holders and part geometries.

WorkNC allows you to select your tool holder and advises the required tool length to use. Or you can input the known tool length and WorkNC will automatically split your cutter paths into logical portions for various available cutters!

The toolpath is automatically modified to avoid potential tool holder collisions with the part geometry, based on the use of a shorter tool length.

The complementary cutter path can now be milled with a longer tool.

Tool Library

Create a WorkNC library for your own tools and for tools available from your suppliers' catalogues. The Tool Library database allows you to define new tools and manage existing ones for WorkNC.

A wide variety of parameters can be associated to each tool in the library.

Users can save time and be more productive by automatically loading these parameters into the current toolpath parameters menu when the required tool is selected.

Machining Sequences

Standardize your processes, on-the-fly, with WorkNC's "Standard Machining Sequences"...

WorkNC keeps a record of your series of cutter paths, holder collision checks, tolerances, tools, etc... so you can use the information again-and-again on similar jobs.

Toolpath Setup Sheets

Data output and journal files pertaining to each job is automatically output from WorkNC. Customization of desired output documentation is also possible.

STL Files

WorkNC reads binary and ASCII stereolithography, "STL", files quickly. STL files are commonly used for rapid prototyping. WorkNC can also refine the STL data for optimal cutting. All WorkNC toolpath types are supported for the machining of scan data.

Mechanically scanned data is also supported and optimized with WorkNC.

WorkNC Industry ...

WorkNC Industry ...