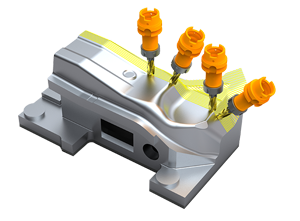

Job Preparation

There is more to programming than just creating cutterpaths. WorkNC contains specialized CAM-oriented CAD functions that can be used prior to programming. Automation tools, such as sequences, can be created to streamline programming. The less time you spend preparing your model for machining, the faster it can be machined.

Features at a glance

-

Automatic model preparation

-

Part analysis tools

-

Filling holes or other open areas

-

Curve creation

-

Tool Libraries and Sequences

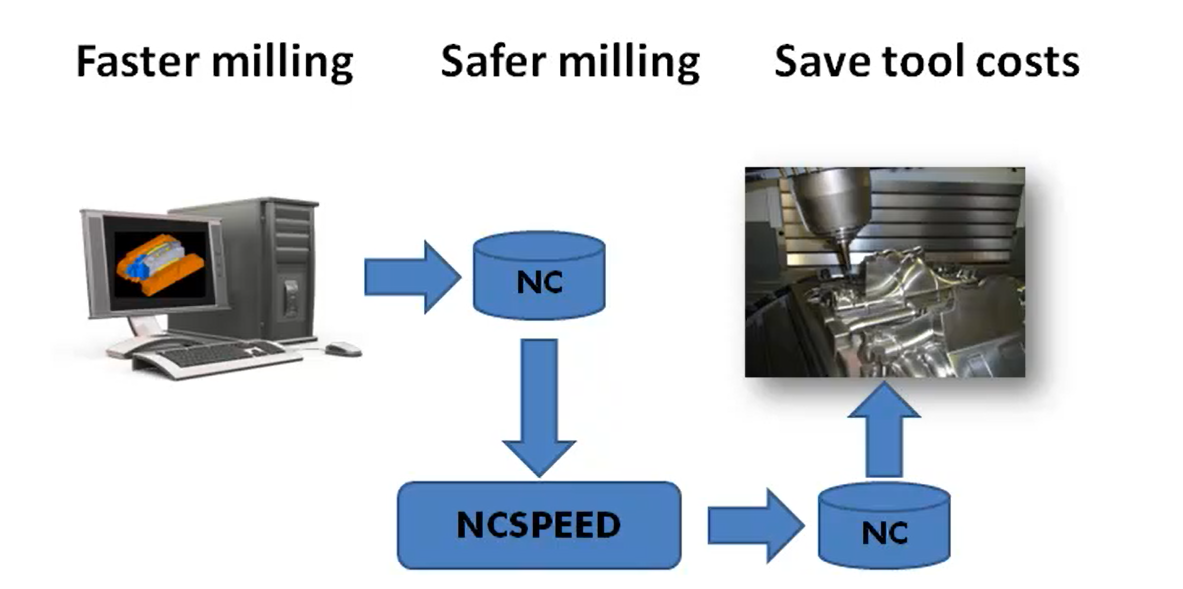

WorkNC provides many tools to augment or automate the machining process. Some are CAD tools that make machining easier, some are CAM automation tools while others are tools that may run automatically in the background. These CAM centric tools are all designed to optimize job preparation so that the user is independent of the design department.

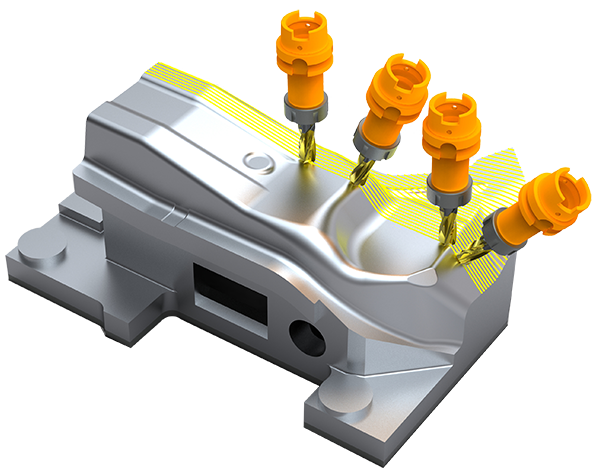

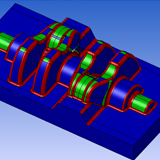

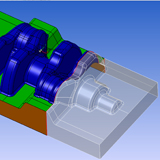

One completely automatic tool involves data integrity and preparation during part loading. Many CAM systems require hours of labor intensive CAD work stitching and healing part geometry before allowing you to make even a single cutterpath. WorkNC, on the other hand, is always ready to create cutterpaths immediately after part loading and initialization. During the initial part activation, WorkNC creates the necessary data elements necessary to create continuous, collision free, reliable cutterpaths the first time.

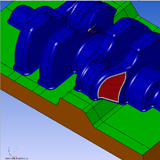

WorkNC’s CAD module contains many design tools to assist the CAM programmer. Analysis tools can be utilized to find corner radii of your part, what the draft angles of the part are, whether there are any undercuts, all flat areas, all vertical areas and more. You can view section cuts at any location, and even turn the section cut into a curve. Surface creation tools can be used to fill small gaps in data, you can blend faces or quickly cover holes or pockets before machining.

Curves can be created as well, either in space, from other curves or from 3D model geometry. These curves can then be used as input for 2D curve machining functions. Curves can also be used as boundaries to contain cutterpaths, or they can be used as drive curves when machining.

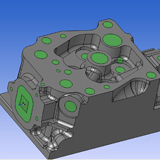

Other tools within WorkNC are utilized to further automate the programming process. Tool libraries can be utilized to store all of the tool parameters for a particular cutter and automatically enter the data when necessary. Sequences can be loaded to provide multiple machining operations, with all parameters at one time, i.e. a Hard Steel Roughing sequence. Sequences can be set up very simply from previously machined jobs.

WorkNC Industry ...

WorkNC Industry ...