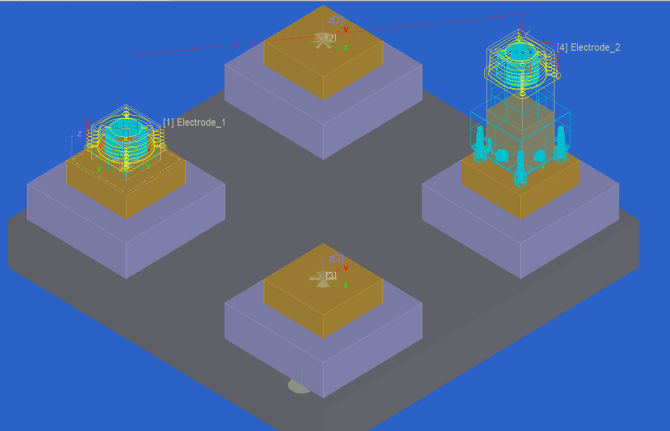

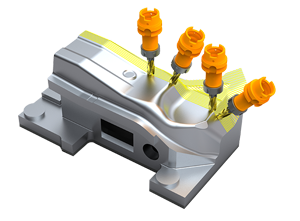

WorkNC MPM (Multi Part Machining)

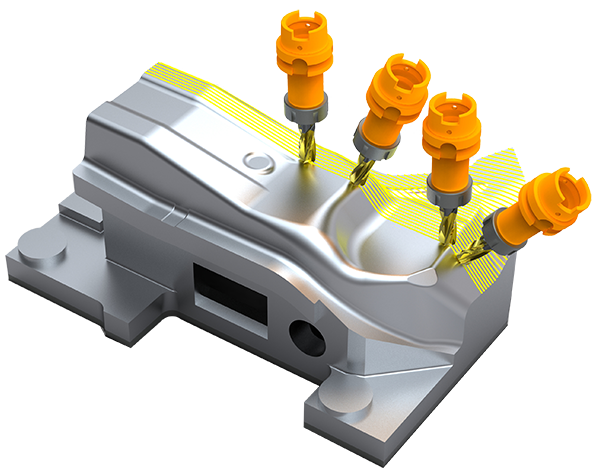

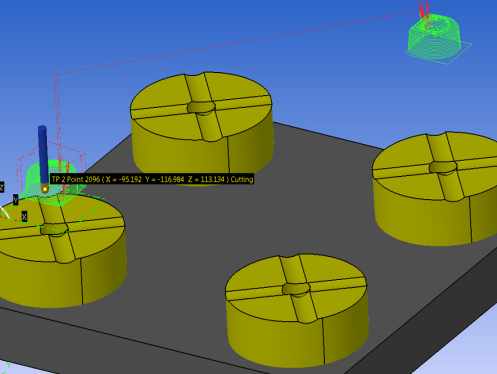

The WorkNC MPM module allows users to easily resolve problems arising from multiple part machining.

Features at a glance:

-

No programming is necessary on the machine,

-

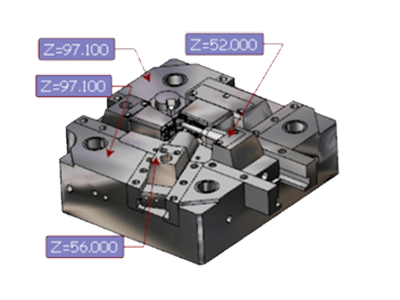

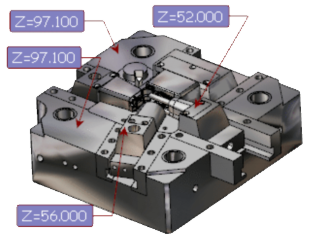

Simple and reliable part positioning,

-

Unsupervised machining,

-

Optimal use of clamping assemblies and palettes,

-

Significant reduction in number of tool changes,

-

Flexibility and adaptability during modifications,

-

Part symmetry and rotation without having to recalculate toolpaths.

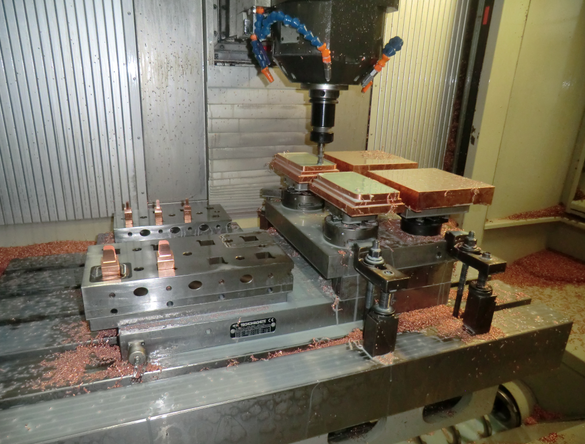

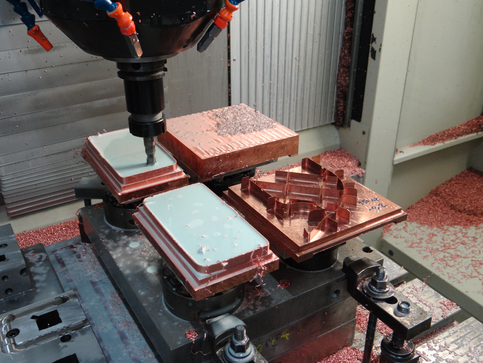

When machining several parts simultaneously on the same machine, operators are confronted by a number of problems arising from multiple tool changes (collision management, down time and lack of precision).

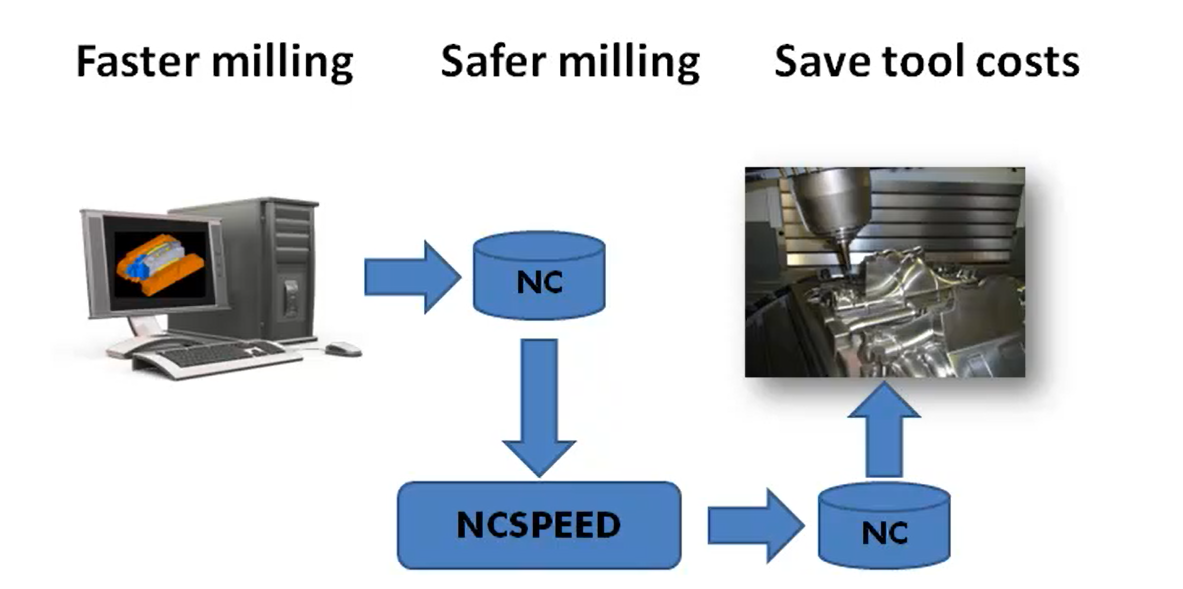

WorkNC's MPM module eliminates these problems and offers real gains in productivity by optimizing machining operations.

This is because no programming is required and no supplementary part origin data needs to be defined.

There is also a significant reduction in the number of required tool changes, problems due to incorrect tool numbering are eliminated, and there are no collisions between the parts.

The use of predefined palette systems ensures rapid and safe machining.

WorkNC Industry ...

WorkNC Industry ...