Engineering

To progress from an order to a finished product requires a considerable amount of technical expertise...

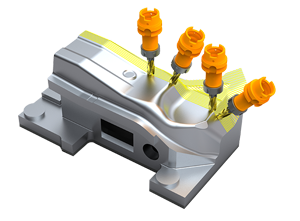

Design data can be supplied in many forms, including IGES, STEP and many other native CAD formats. Successful importing of the customer's data is just the first step. Surfaces and models may need repair, and designs may require modification or editing before production can commence. For moldmakers a tool has to be constructed around the cavity.

WorkNC includes powerful tools to facilitate all these tasks. The software is able to perform Boolean operations, patch surface gaps, analyze draft angles, and create split lines and much more….

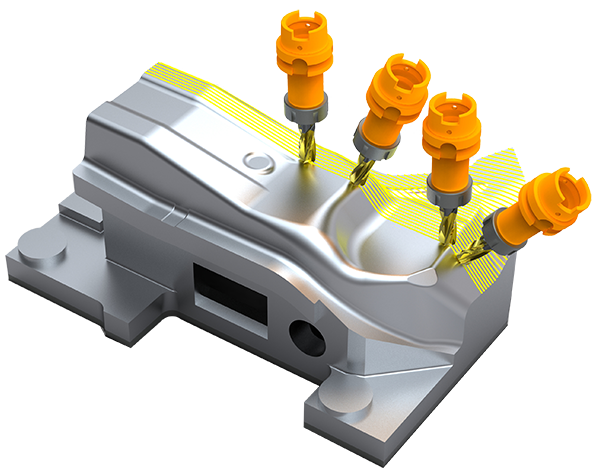

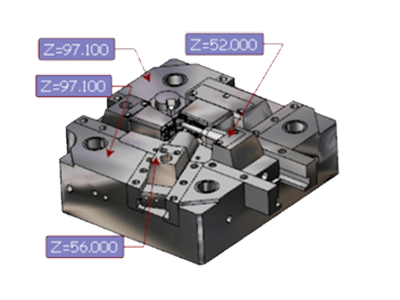

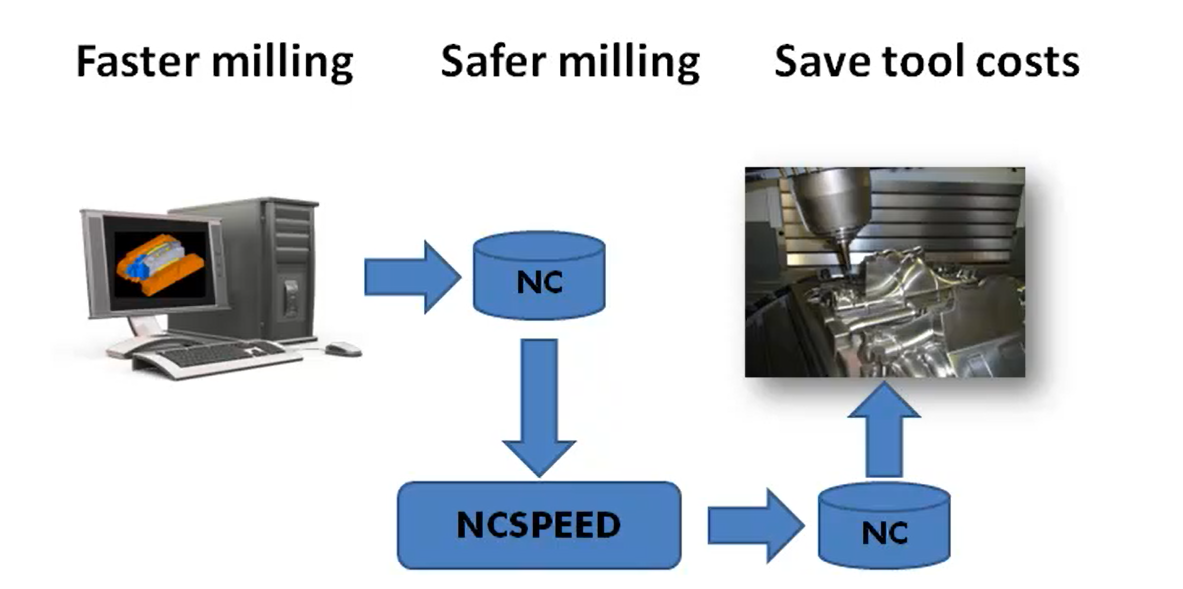

Once the part or mold is ready for production, WorkNC can rapidly and automatically build toolpaths. For consistency, existing methods can be stored and reused, capturing engineer's knowledge and experience. All the WorkNC toolpaths have been designed to produce optimized and safe cutting conditions, while verification and collision avoidance ensure reliability even for the most complex 5-axis paths, helping users to produce high quality products with the minimum of effort.

WorkPLAN solutions, the ERP manufacturing management solution can also help engineers to manage the process, keeping track of design iterations, hours worked, expenditure and the progress of production. The systems enable managers to monitor, in real time, all their key business drivers, allowing them to deliver products both profitably, and on time.

WorkNC Industry ...

WorkNC Industry ...