WorkNC 5-Axis Machining

WorkNC brings the benefits of 5-Axis machining to all users by taking the complexity out of 5-Axis machining. WorkNC 5-Axis includes powerful, easy-to-use programming and integrated collision avoidance.

With WorkNC, 5-Axis programming is easy, safe and reliable allowing you to automatically generate 5-Axis toolpaths for the majority of your jobs.

Features at a glance

-

Efficient toolpath generation

-

Easy toolpath preparation based on guide curveset, sections or surfaces.

-

Auto 5: Automatic conversion of 3-Axis toolpaths to 5-Axis

-

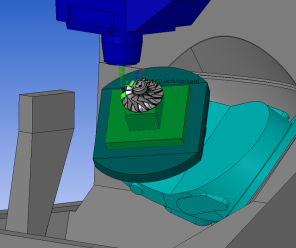

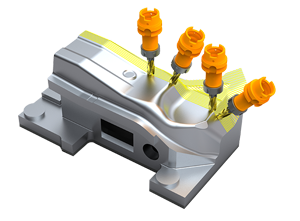

Specialized strategies for individual applications such as trimming, pocketing, blade and tube machining, impellers and laser cutting

-

Complete simulation.

WorkNC Auto 5

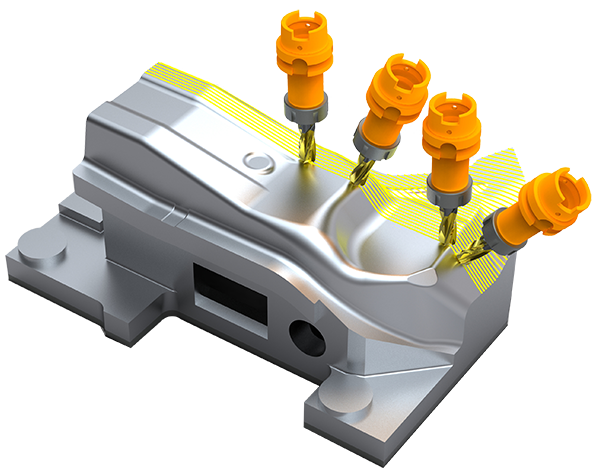

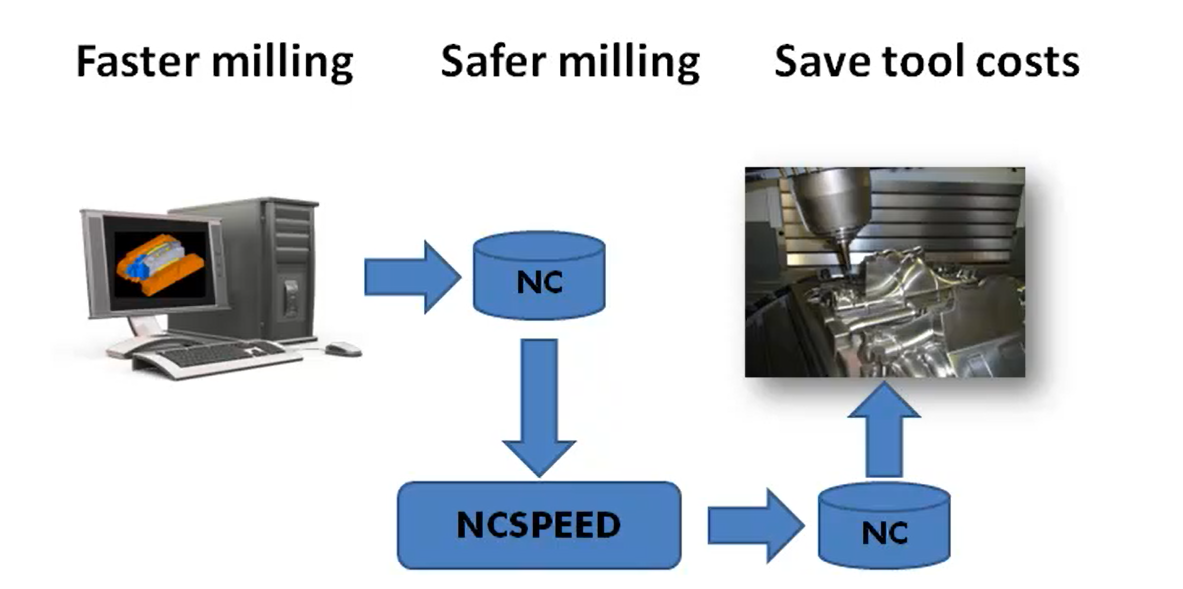

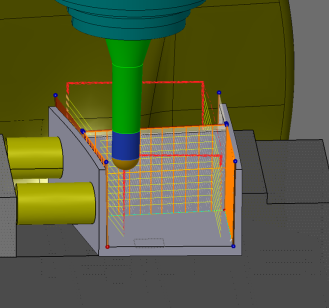

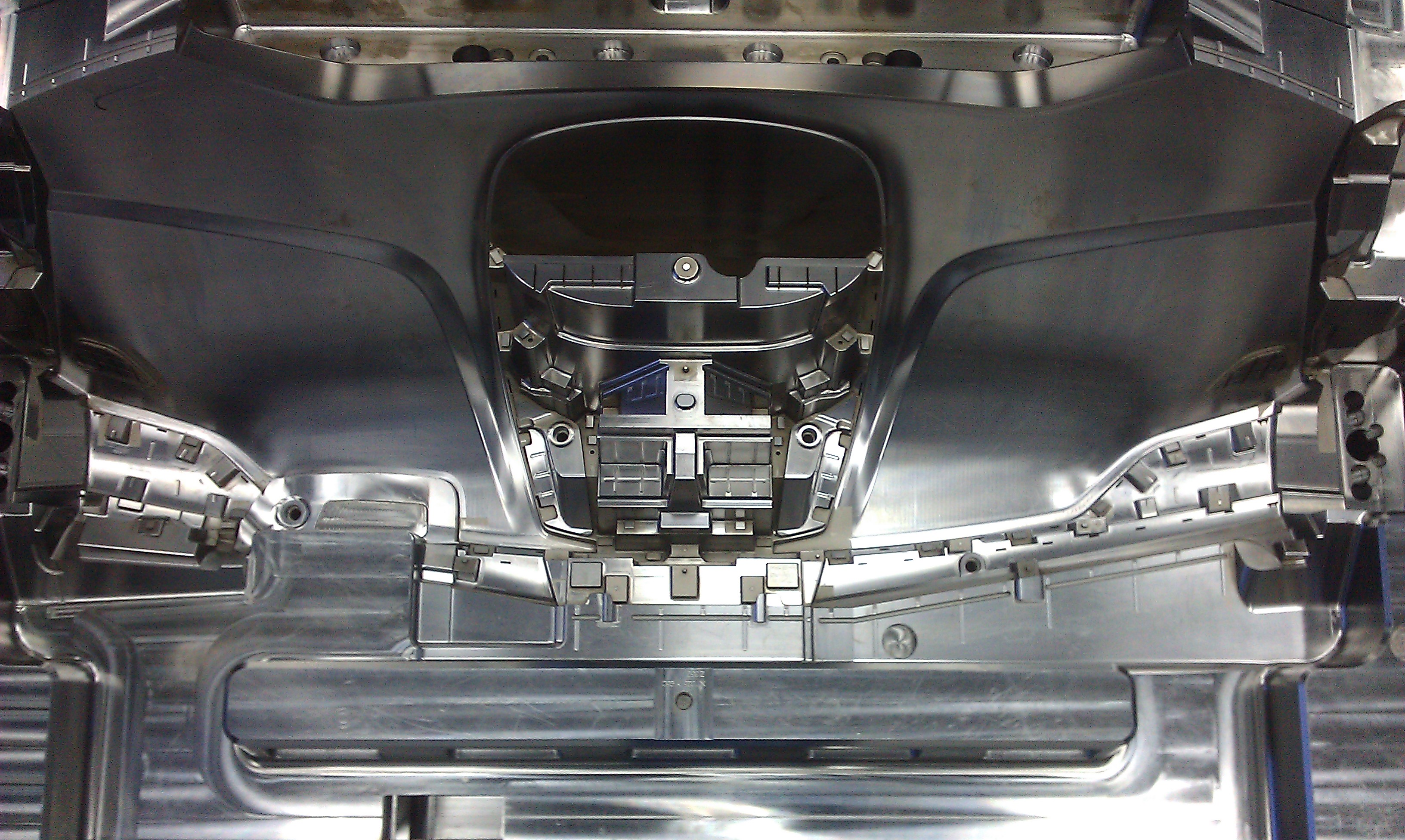

WorkNC Auto 5 is a truly unique and revolutionary innovation in the field of 5-Axis machining. Users can now automatically generate 5-Axis toolpaths based on existing 3-Axis toolpaths while taking into account the specific kinematics of the 5-Axis milling center selected.

WorkNC Auto 5 automatically generates collision free 5-Axis toolpaths from existing 3-Axis toolpaths. It enables the use of short, rigid cutters and allows more of the job to be finished in one setting, reducing the number of electrode burning operations required to finish a component.

Simultaneous 5-Axis Machining

The WorkNC Simultaneous 5-Axis Machining module enables the user to directly generate 5-Axis toolpaths in relation to the 3D geometry of the part.

These continuous 5-Axis toolpaths enable users to quickly machine the most complex parts with the highest level of reliability reducing the number of different setups for machining completely a part.

Easy to use, WorkNC's different strategies will allow you to rapidly generate 5-Axis toolpaths specifically for your machine in no time.

Standard toolpaths are sorted into 3 categories (based on guide curveset, sections or surfaces) to make job preparation easier and to ensure quick toolpath creation.

For optimum results, the user can get a preview of his toolpath and make changes - for smoothing, adding lead angles, determining tool direction – to ensure maximum tool life.

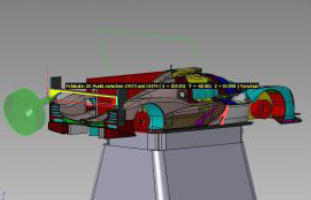

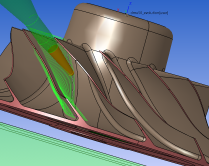

5-Axis Graphical Display and Simulation

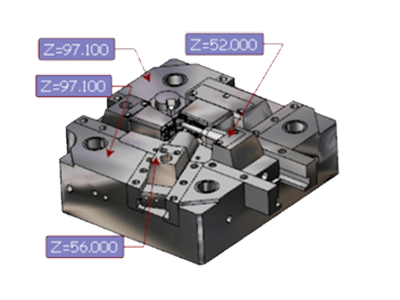

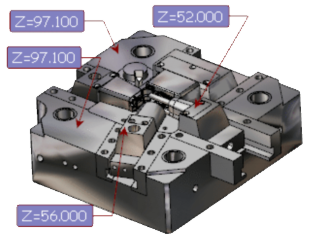

Ensures efficient display for the simulation of 3, 3+2 or 5-Axis toolpaths together with the kinematics of the selected machine.

The 5-Axis graphical display also detects potential collisions between the different moving elements (parts, tools, tool-holders, machining heads, ...). Users can also create their own new virtual 5-axis machine representations.

WorkNC's 5-Axis machining solution has been designed and tested to be as easy and as reliable to use as WorkNC 3-axis machining.

The WorkNC 5-Axis machining solution is the best choice for reliable, productive results.

WorkNC Industry ...

WorkNC Industry ...