Many manufacturers have moved their CAM programming directly to the shop floor. Advantages often cited range from shorter lead times to programming flexibility on the shop floor.

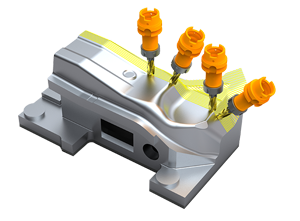

WorkNC, with its automatic functions and easy to use interface, is an ideal tool for shop floor machining.

Features at a Glance

-

Easy to use interface with a short learning curve

-

Efficient CAM programming

-

Fast calculations

-

Automatic milling routines

-

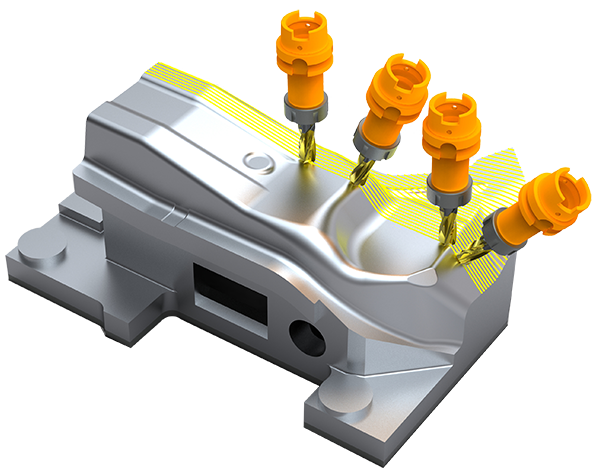

Tool holder collision checking for secure use of short tools

WorkNC has an intuitive user interface without unnecessary sub menus or excessive options. This streamlined interface allows for a short learning curve. Program your parts by inputting a few basic milling parameters and calculate collision free toolpaths. Automate the CAM programming through templates and libraries, to program your parts in the shortest time possible.

Automatic milling functions make programming even easier and faster. WorkNC contains automatic roughing and reroughing routines that utilize a dynamic stock model to keep track of the stock condition along the way. Automatic finishing, including rest milling, allows you to program the finest details quickly and efficiently.

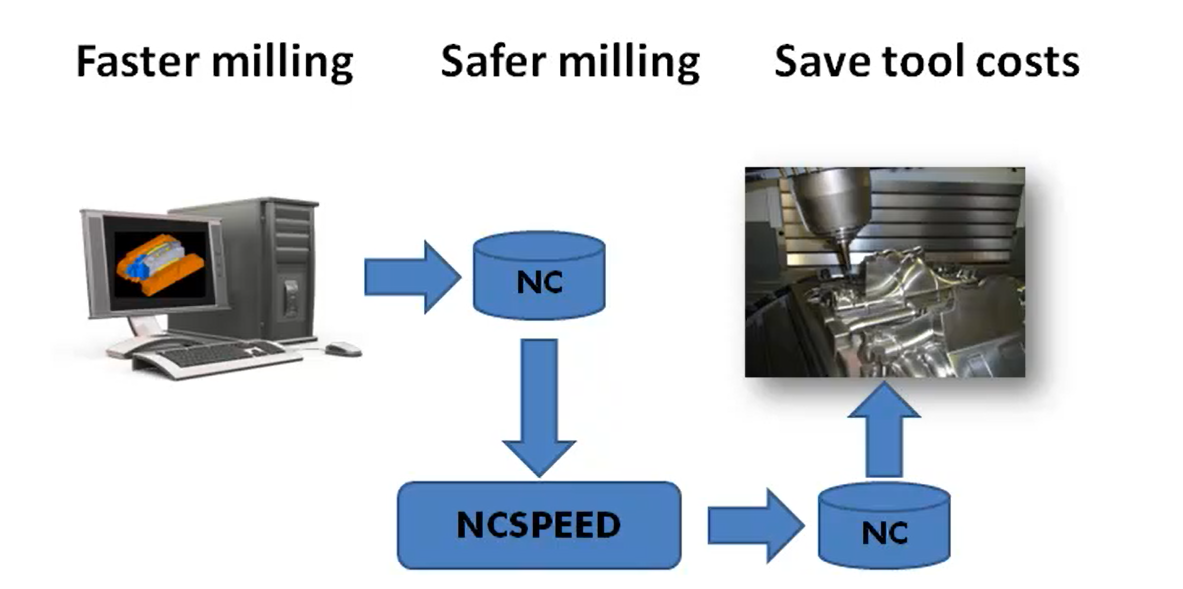

WorkNC is not just fast to program, but it calculates quickly also. Through the use of efficient algorithms, 64 bit programming, multi-threading and parallel processing; WorkNC is able to calculate cutterpaths on the largest, most complex parts in minutes instead of hours. Lightning fast calculations are combined with the automatic cutterpath functions to dramatically shorten the amount of time necessary to program your parts.

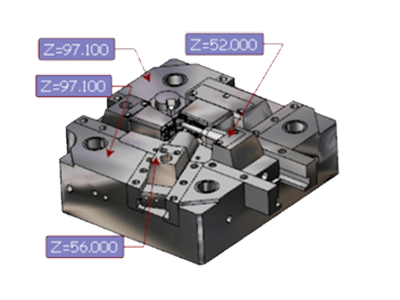

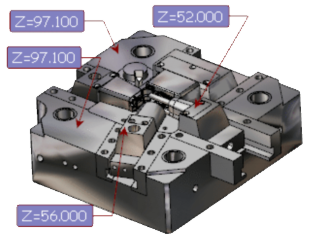

Fast programming means little without the proven reliability of the cutterpath calculations to back it up. WorkNC’s cutterpaths are automatically checked to be collision free during all stages of programming. WorkNC creates the highest quality cutterpaths available, where users are so confident in them that they often run them without performing a verification simulation. Cutterpaths can be checked with the tool holder to allow the use of the shortest tools, while maintaining a collision free milling environment.

Ease of use, fast calculations and high reliability make WorkNC an ideal choice for programming directly on the shop floor. Parts can be programmed as they are needed, condensing the amount of lead time needed for programming. Shop floor programming reduces the time necessary to implement changes or alterations. It allows those most familiar with the individual milling machines to program for them.

WorkNC Industry ...

WorkNC Industry ...