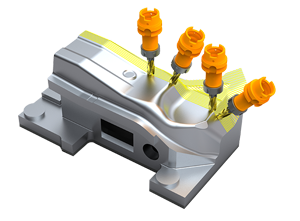

The production of

complex dies and moulds is part of your daily routine. To stay ahead of the

competition, fast and cost-effective machining is essential. This requires a

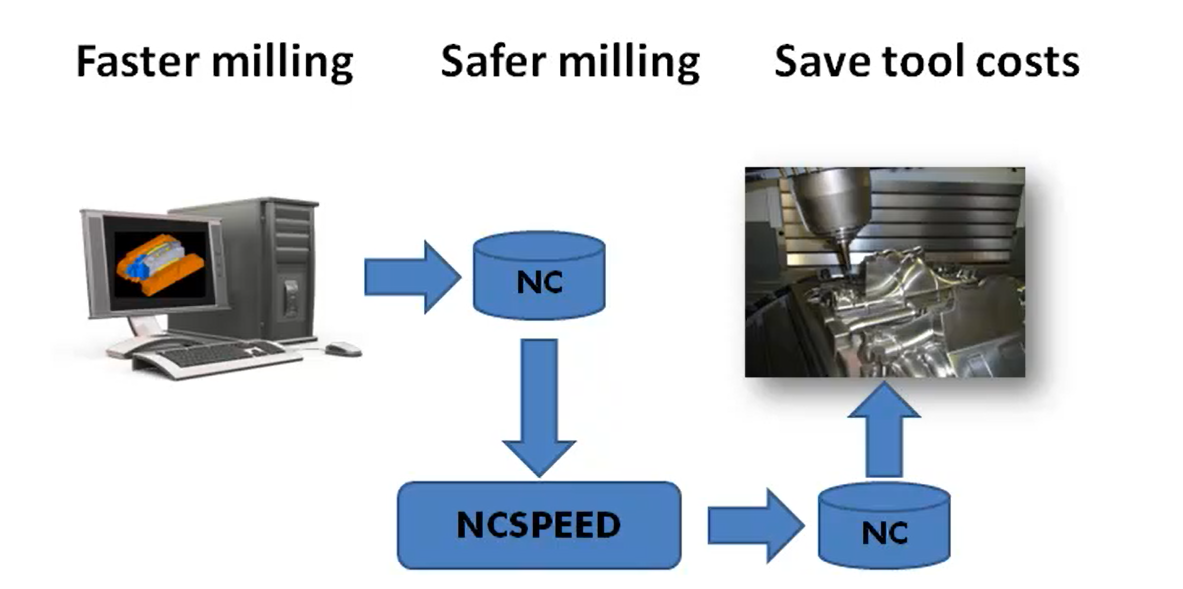

close and efficient interaction between all elements of the process chain CAM

system, milling machine, control system and cutting tools. By automatically

adapting the feed rate to changing machining conditions, NCspeed helps

you tap the unused potential of your operating resources. This optimizes the

performance of both machine and tool to cut milling times by up to20 percent.

Optimizing feed

rates to cut costs

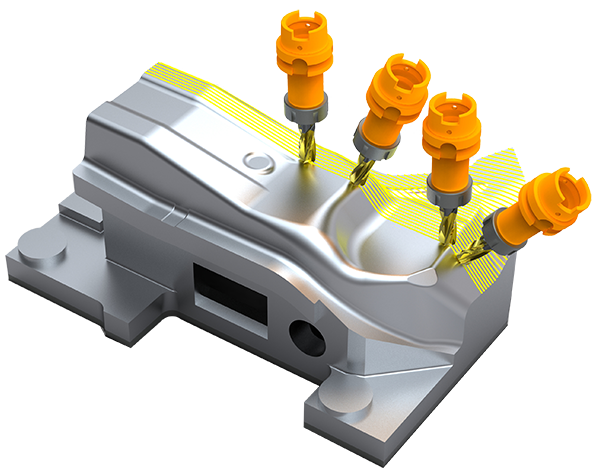

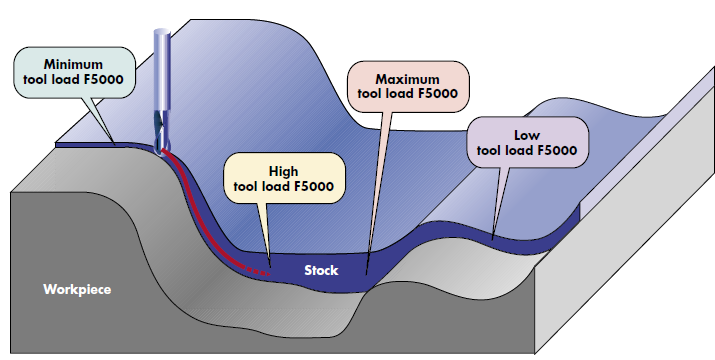

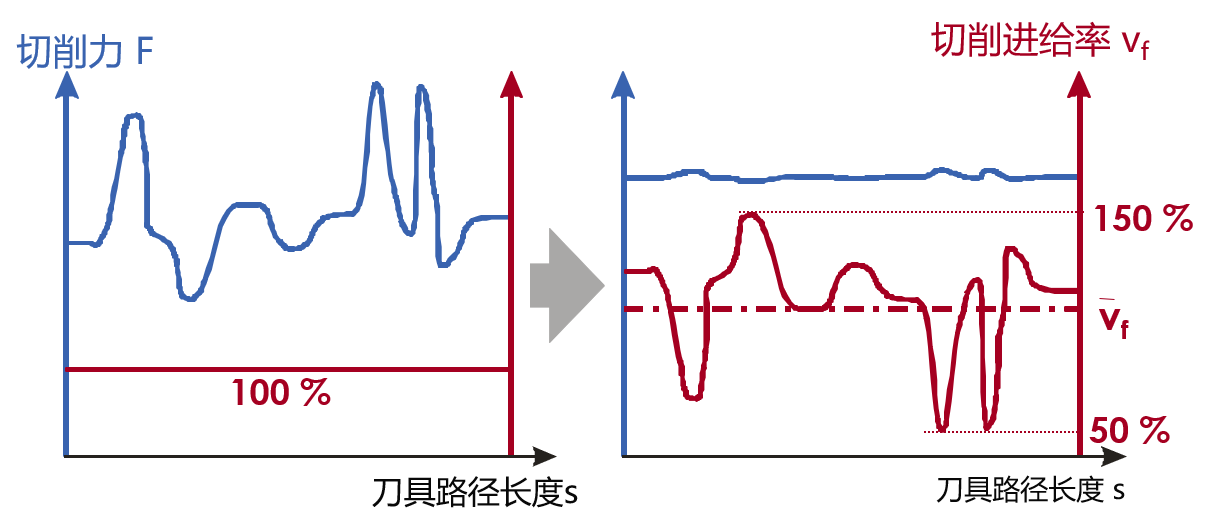

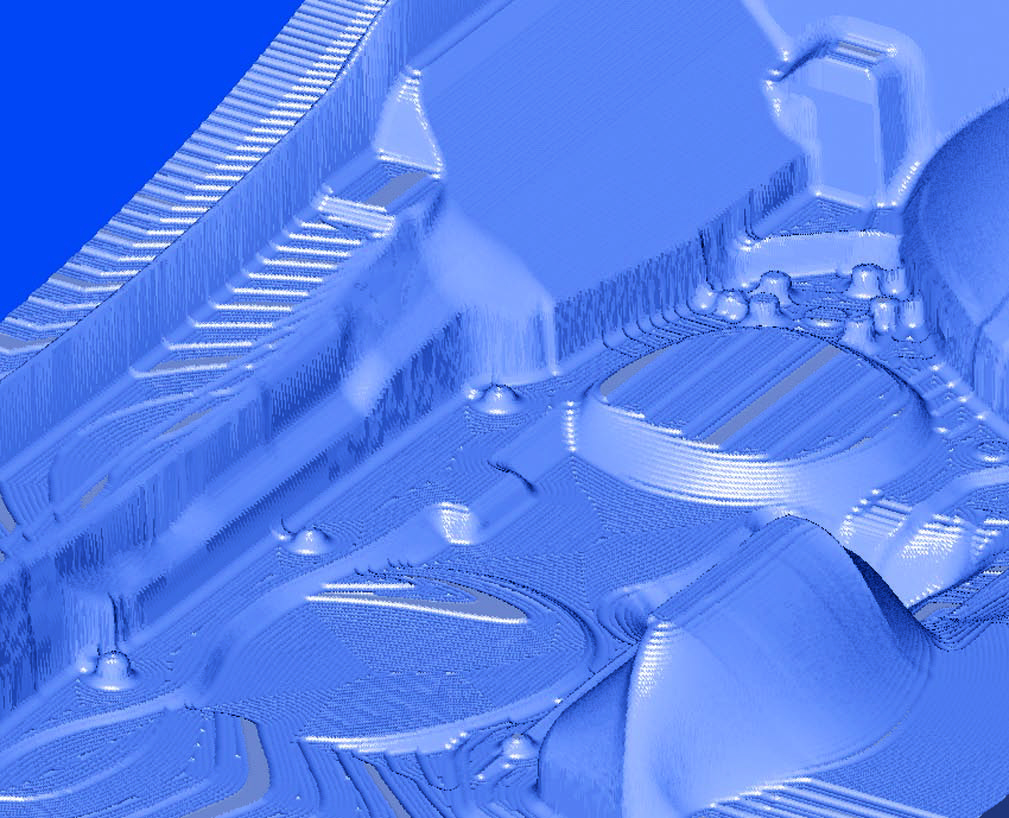

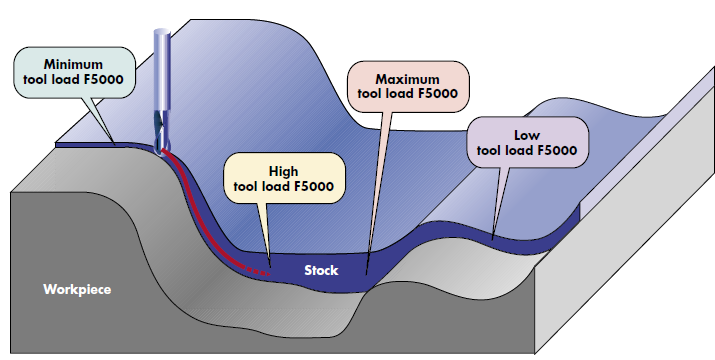

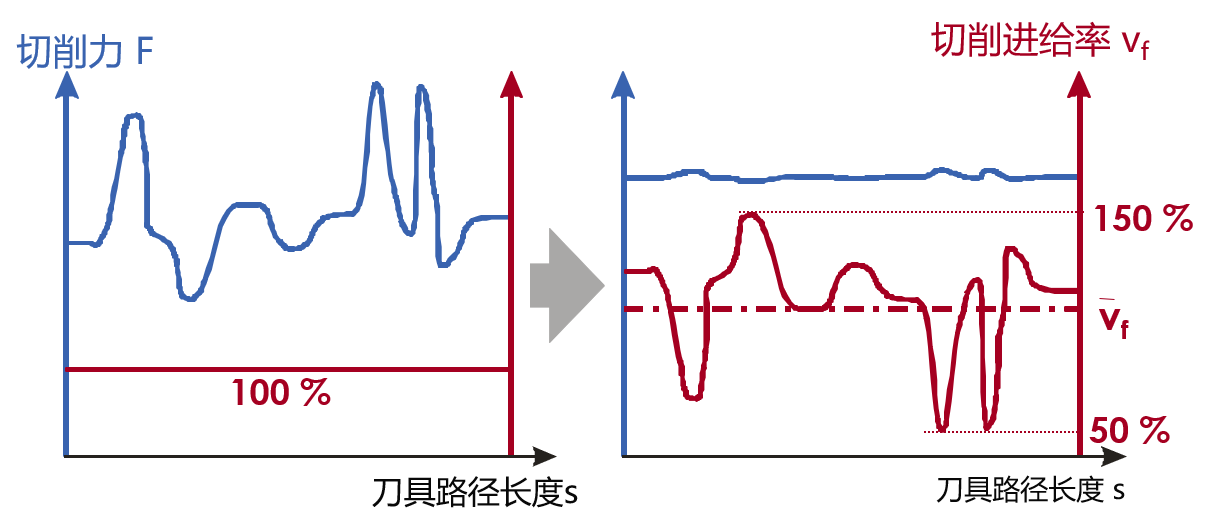

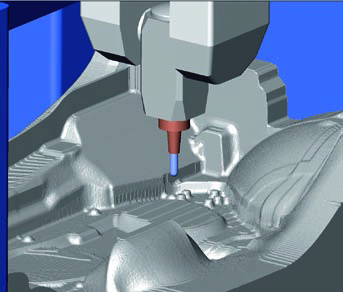

NCspeed analyzes and then optimizes your NC programs. Based on a

simulation of the machining sequence, NCspeed calculates the volume of material

to be removed for any tool position as well as the resulting tool loads. In

areas with low cutting volume and favourable milling conditions, NCspeed

increases the feed rate. In critical areas the feed rate is not changed. With

the modified NC program, the machine tool works with a higher average feed

rate to cut machining times and optimize the utilization of your available

machines.

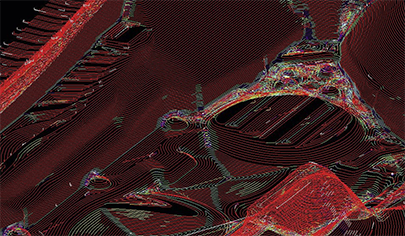

Optimized NC program: the colours indicate

the federates

Optimized NC program: the colours indicate

the federates

Red

= fast , blue = slow

Key

feature:Fast, reliable milling

In a simulation of the machining process, NCspeed determines the loads

that would be generated in the actual process and compares these values with

the tool's user-specified load limit. NCspeed then automatically detectsany

critical areas and reduces the feed rate to prevent costly tool damage and

scrapped workpieces.

Key feature:

Reducing tool costs

One might assume

that the feed rate adjustment works purely on the principle "less material

= faster the feed rate". This is far from the truth: Often, machining

conditions can be unfavourable even if only a small amount of material is

removed.

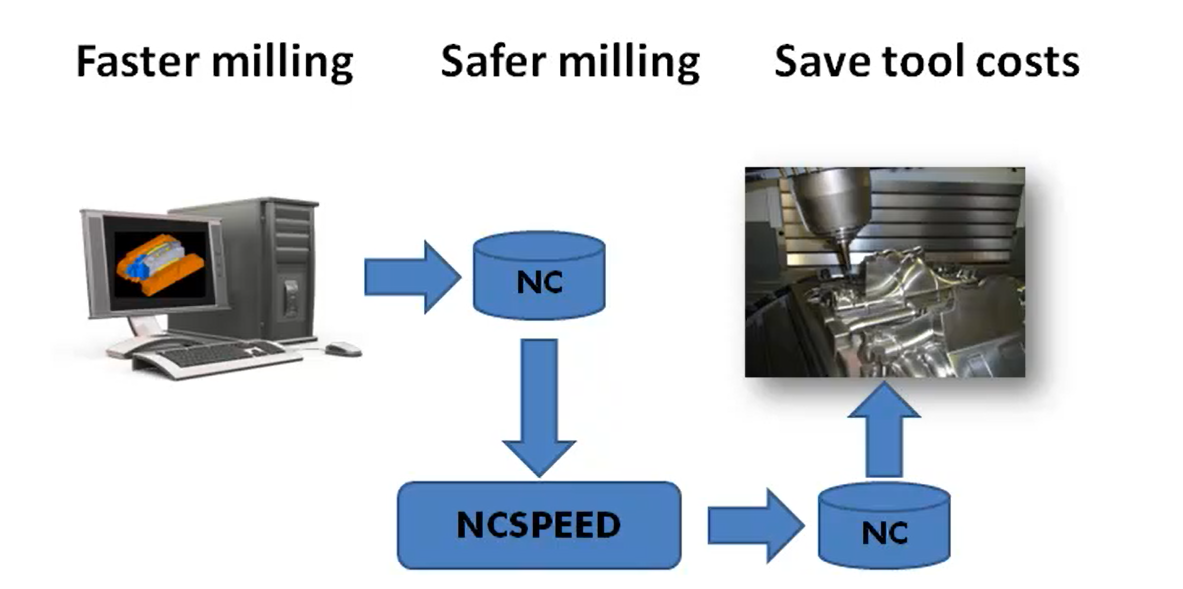

Key feature:

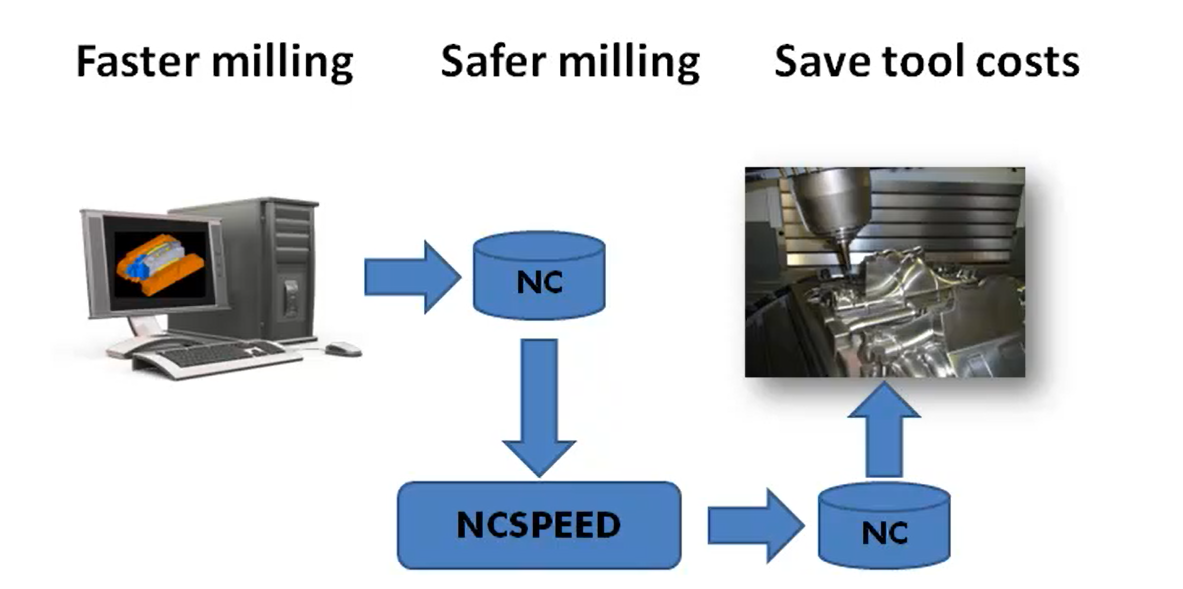

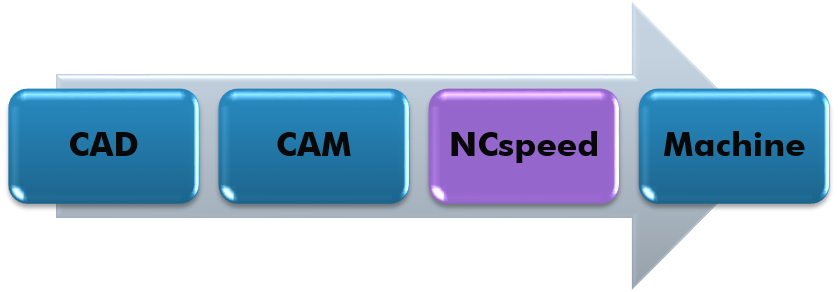

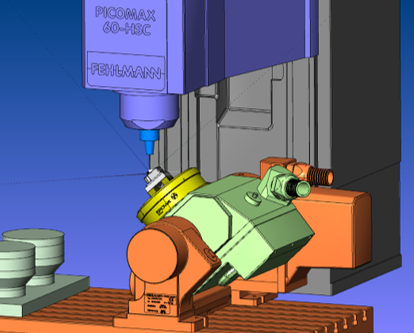

Processchain integration

The NC programs generated withyour CAM system are automatically processed

by milling machines and controllers. NCspeed integrates seamlessly into the

process chain, fitting neatly between CAM system andmachine controller. Highly

customizable, it interfaces with your CAM system, from which it receives the

information it needs to optimize the NCprogram. NCspeed runs almost fully

automatically with minimal user input.

Key feature: Fast

simulation

To make an optimization viable for one-off production, the software must -

inaddition to integrating seamlessly be fast so as to minimize processing

times:A fast optimization process cuts thetotal production times, reducing

the process's overall efficiency. NC-speedis capable of rapidly processing

evenvery large NC programs. Our customers include manufacturers of large sheet

metal forming tools with NCprograms exceeding I O0 MB in size.

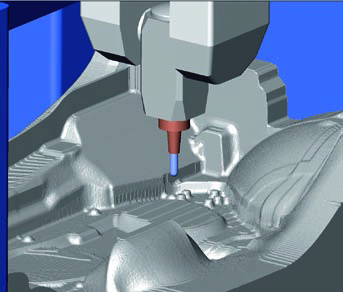

In roughing on a

constant Z-plane, for example, the cutting tool may encounter raised workpiece

sections located centrally within its path. Approaching these with a cutting

insert tool at highspeed can cause tool vibration, which would dramatically

reduce the tool inserts' service life. NCspeed's adaptive feed rate control detects

such situations and reduces the feed rate accordingly to increase tool life.

Key

feature:Staying in the picture

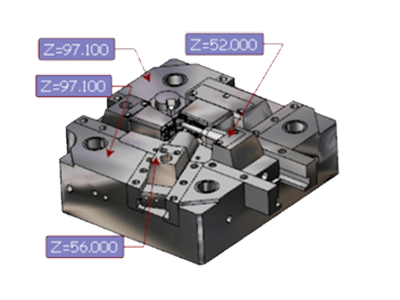

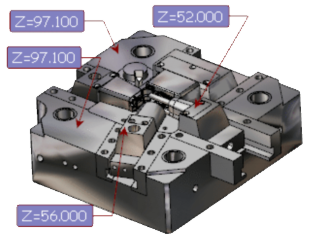

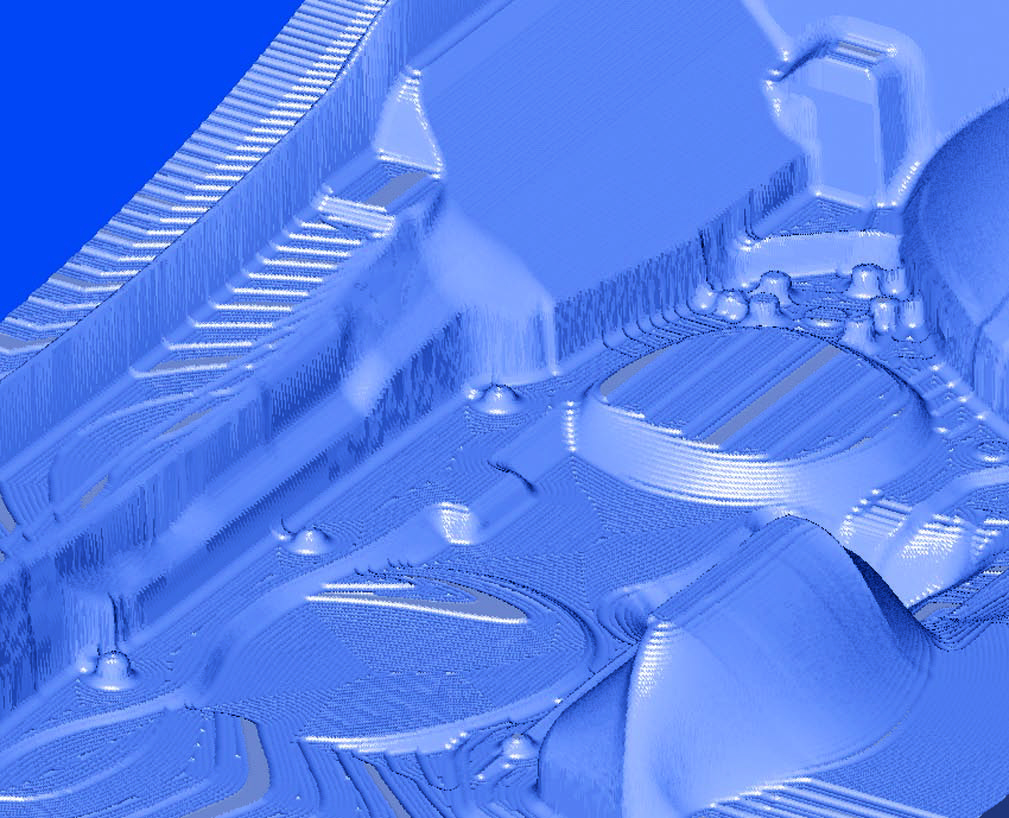

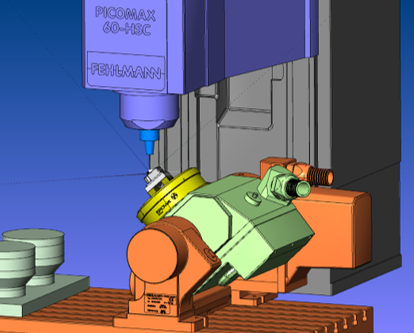

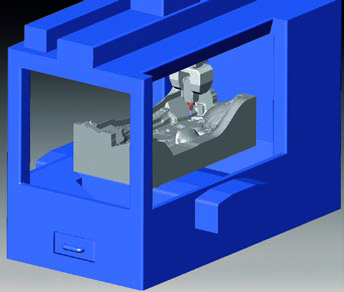

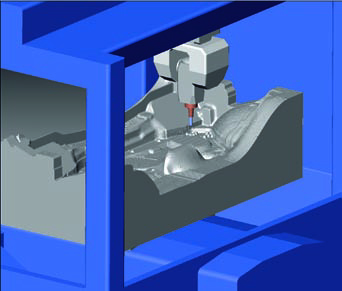

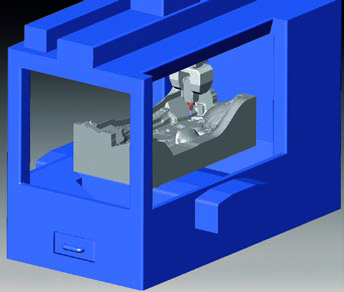

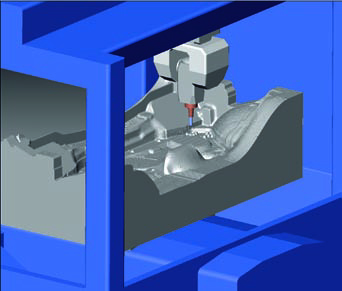

In addition to

ensuring the optimum feed rate at all times, NCspeed's machining simulation

generates a detailed, accurate image of the resulting workpiece. An analysis

of the quality of the workpiece surface provides valuable information about the

quality of your NC programs, which you canuse to further optimize your

toolpath files and eliminate potential problems in advance.

NCspeed also features

comprehensive collision checking functionality, which detects collisions between

tool, workpiece and all other machine components with a collision potential.

Based on the postprocessed data, the collision check reliably detects even

postprocessing errors.

WorkNC Industry ...

WorkNC Industry ...