Whether NC programming is done on the shop floor or by a separate programming department, it can always be advantageous for the shop floor to be able to load the CAM data.

WorkNC Toolpath Viewer provides machine operators the ability to load, analyze and simulate the CAM programming prior to running it on the mill. They can post process for their mill, but they cannot edit or change a cutterpath. This can provide more information than printed process sheets, allowing for fewer work interruptions later.

Features at a glance

-

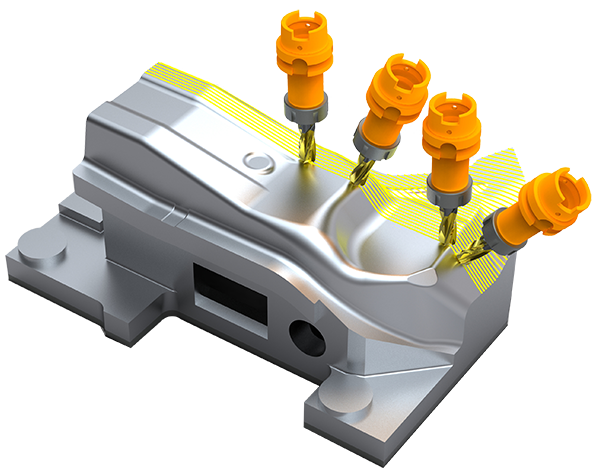

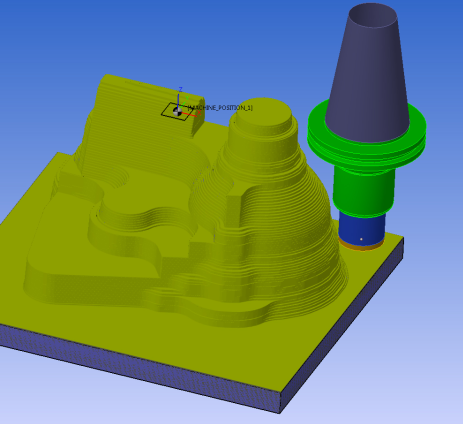

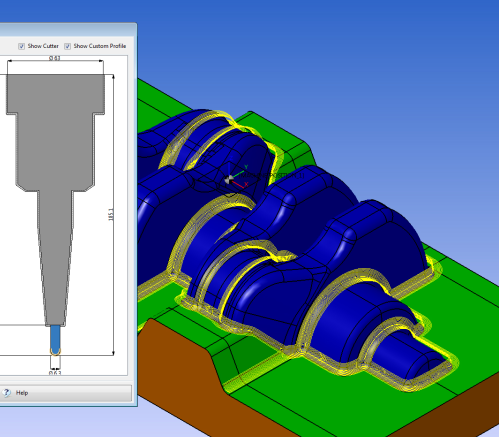

Display and simulate cutterpaths

-

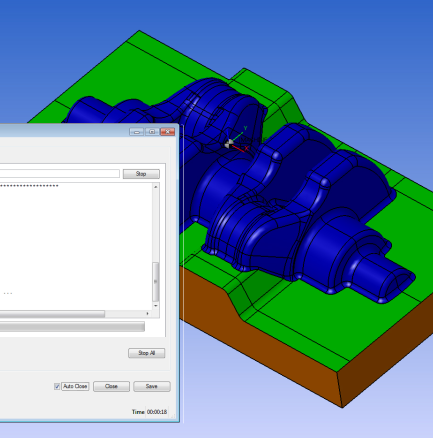

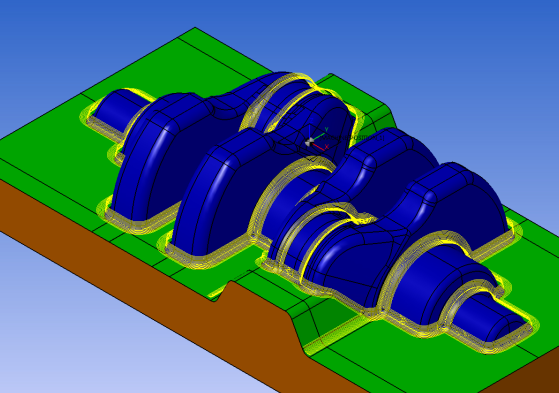

Display stock condition before and after each operation

-

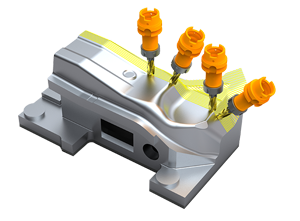

Perform machine simulation and collision checking

-

Post process the cutterpaths

-

Go paperless

-

Not tying up a full WorkNC license for part viewing and post processing

WorkNC Toolpath Viewer is an ideal tool when not programming directly on the shop floor. This low cost yet high value product allows you to open WorkNC CAM files for viewing, analyzing, simulating, verifying and then post processing without the need for tying up a full WorkNC programming license. Machine operators can load a WorkNC workzone and check the part or cutterpath anywhere, without interrupting a programmer or stopping what they are currently doing.

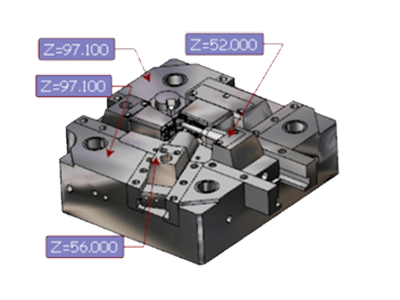

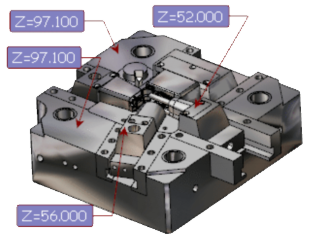

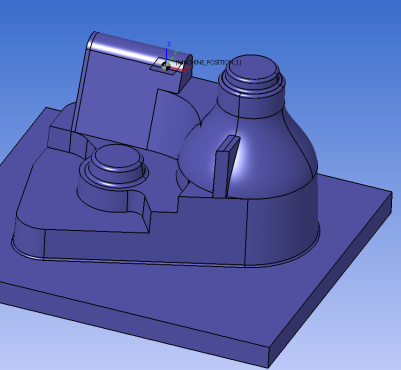

WorkNC Toolpath Viewer is the perfect complement to programming with WorkNC. Users can analyze the CAD data for features such as radii, draft angles, backdraft, undercuts and do section cuts anywhere on their data. They can verify whether the part will be milled completely, or if residual stock will remain.

Besides analysis of the CAD geometry, users can simulate the cutterpaths. Users can check the condition of the stock at each stage of the milling process, seeing where material to mill remains. They can verify keyways, hole locations and other features. WorkNC Toolpath Viewer works in 3+2 and 5-axis also, allowing for a visual, and computer calculated, double check of all machine rotation angles.

Go paperless by using the WorkNC Toolpath Viewer. View all process documentation related to the job without the need to print it out. Examine all programmed feedrates, spindle speeds, tool lengths, tool holders and more before running the part on the mill.

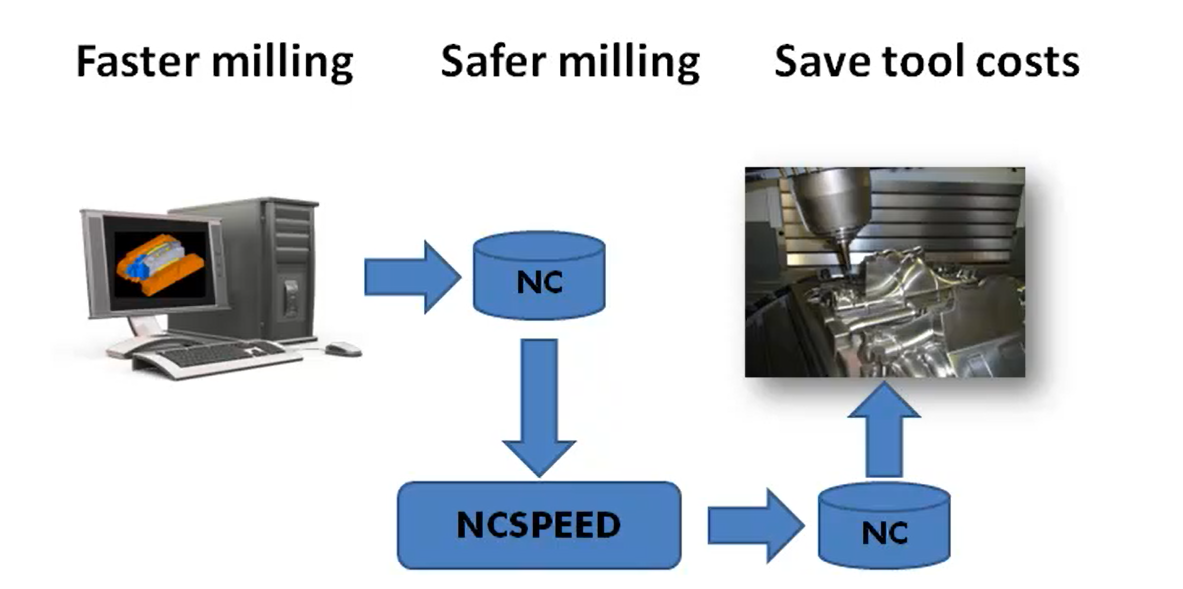

Once the milling machine to be used is known and available, WorkNC Toolpath Viewer can post process the toolpath for that individual machine. This allows the programming department to get ahead on jobs, and the running of the job once a machine is available. This saves from the scheduling irregularities that often occur in a fast moving environment, and allows the shop flexibility in reducing unscheduled mill downtime. This also allows you to optimize for the mill, for example, you may rough a part on one mill, move it to a second mill for finish operations and a third mill for 5-axis work.

WorkNC Industry ...

WorkNC Industry ...