WorkNC 2D & Hole Machining

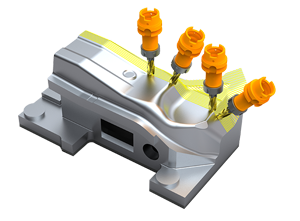

WorkNC’s 2D & hole boring functions provide a complete solution to milling simpler, prismatic parts, or to program all of the holes designed in your parts. WorkNC’s 2D and hole boring functions can work on curve geometry, surface or solid geometry, and can program the holes whether they were designed in the CAD model or not.

Features at a glance

-

Perfect for less complex, prismatic parts

-

Includes curve and surface milling functions

-

Completely automatic generation of drilling operations

-

Accounts for deep holes and intersecting holes

-

Holes can be in any angled inclination

-

Can mill in any inclination also

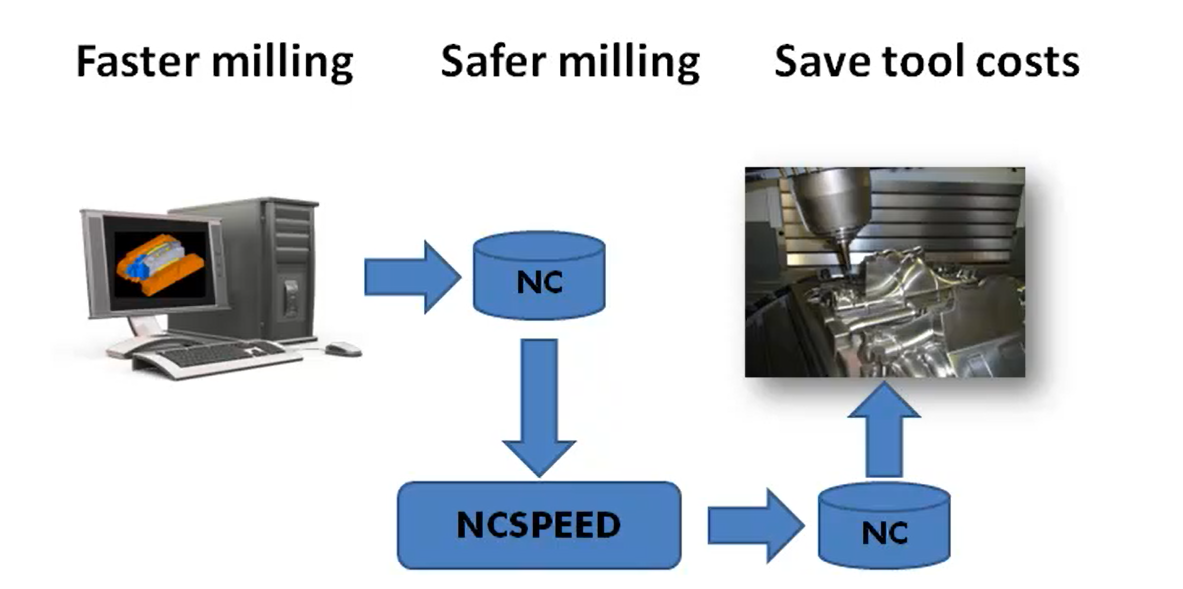

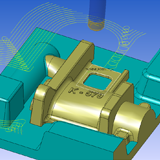

When it comes to simpler geometries, WorkNC has you covered. 2D cutterpaths on curves or surfaces are combined with automatic and manual hole programming functions to provide a complete solution for prismatic parts, or any and all of your hole boring needs.

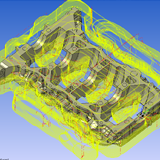

WorkNC contains 2D curve machining functions for machining directly from independent 2D entities or curves extracted from 3D models. To make programming even faster, many of the 2D functions can be done directly on a solid face without the need to extract curve geometry.

WorkNC’s 2D machining functions can perform 2D pocketing, profiling, curve rest machining, engraving, chamfering, facing and other common 2D milling tasks. Although these are traditionally referred to as 2D machining options, these curves need not be constrained to a 2D plane. Functions like engraving, rest machining and profiling will work on non-planar 3D curves just as easily.

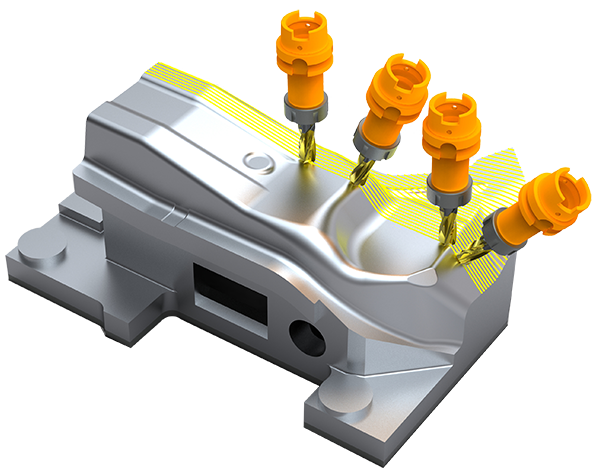

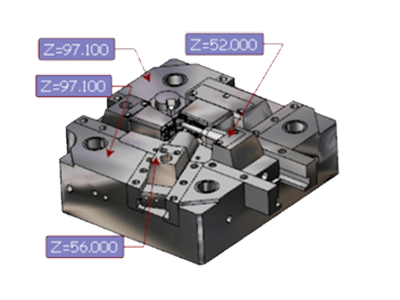

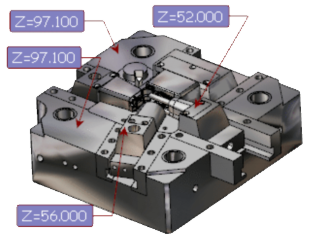

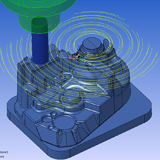

Feature Recognition is used for automatic hole machining. WorkNC can find and mill all cylindrical shapes, regardless of the vector or plane. Pre-defined templates allow for programming hundreds or thousands holes in just seconds. Intelligence is built in for safely machining deep holes and for instances where you have intersecting holes in your parts.

Besides the automatic hole detection and milling, you still have full functionality for manual hole functions. This is used when you just need a quick hole, without adding it to your template ahead of time. Even if the holes are not designed into your CAD model, you can still program them through the use of simple point sets.

WorkNC’s 2D milling functions, as well as the automatic and manual hole milling can be used along any machining vector. Advanced 3D features such as tool holder and machine collision checking can be used on these 2D cutterpaths with your solid or surface model to ensure a safe milling environment.

WorkNC Industry ...

WorkNC Industry ...