For the rapid manufacture of prototypes and models and efficient management of the processes involved look to WorkNC...

Time to market for new products is important for success, and prototypes and models help to finalize the design. WorkNC is a powerful tool for rapid prototyping, providing an alternative to additive methods of model creation by machining components and models directly, or by machining a mold where parts are required in low volume. The resulting prototypes can be made in resin or the material intended for production to allow accurate assessment of functionality and appearance.

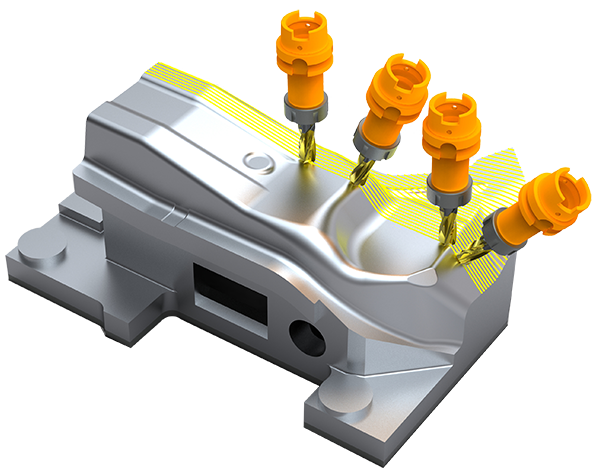

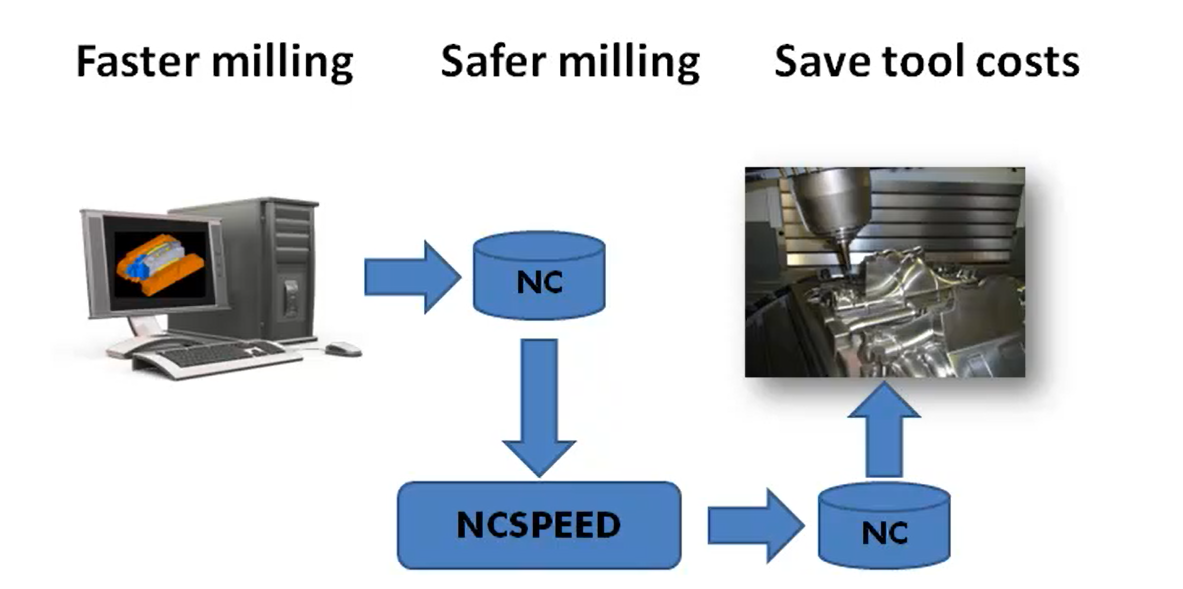

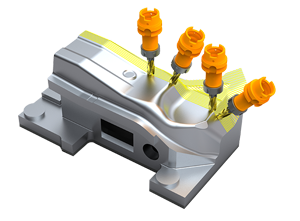

Working directly from the CAD model, WorkNC can create a split line and check draft angles to ensure moldability and machinability. The software's automatic programming will quickly produce a toolpath while avoiding tool and tool holder collisions. For 5-axis machining centers, which are commonly used by rapid prototypers, WorkNC's Auto 5 converts 3-axis toolpaths into 5-axis toolpaths, enabling more of the part to be machined in one setting and allowing the use of shorter and more rigid cutters, especially useful for achieving fine detail. In addition, WorkNC is renowned for the reliability of its toolpaths, so being able to run machine tools unmanned and produce a high quality surface finish will reduce production time to a minimum, eliminate hand finishing and keep costs down in this competitive industry.

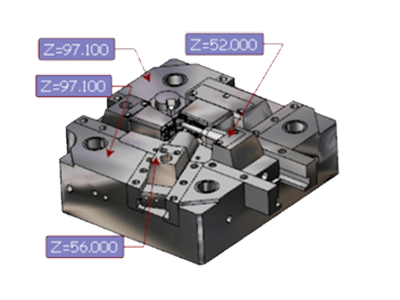

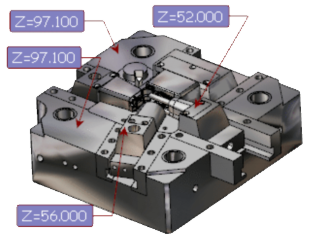

WorkNC also provides special layer milling routines, designed for machines that build prototypes by adding layers of material. The WorkNC Layer Milling Process (LMP) involves slicing the model and producing a machining profile for each layer. Furthermore, the software can provide a path for the application of adhesive between layers where necessary. As the layers are cut and added, WorkNC will generate the completed model, allowing the production of parts which would otherwise be very difficult to machine.

Keeping track of individual projects and ensuring they are completed on time and at a profit is demanding when delivery times for models an prototypes are measured in hours. WorkPLAN Solutions, the ERP for custom manufacturing management systems control capacity planning, provide accurate quotations and monitor costs. Real time information provided by the software highlights anomalies as they occur, allowing managers to take appropriate action to maximize productivity and profitability.

WorkNC Industry ...

WorkNC Industry ...